Wax oil filtration and separation control device and working method

A technology for filtration separation and wax oil, applied in the direction of filtration separation, separation method, purification by filtration, etc., can solve the problems of low device control flexibility, inability to realize wax oil pressure, temperature monitoring and filter element blockage, etc., to achieve The effect of saving manual operation cost, stable operation and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

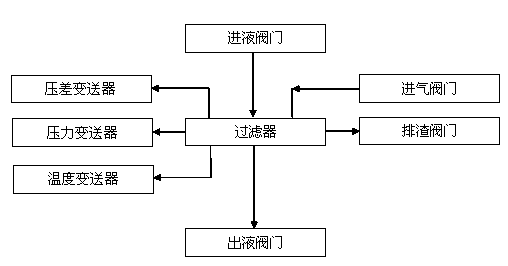

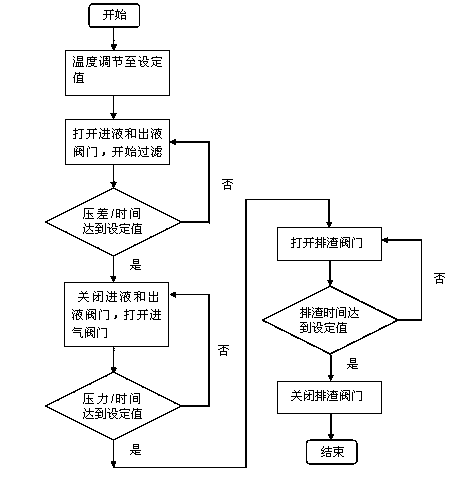

[0016] Such as figure 1 As shown, the specific embodiment of the present invention mainly includes the following steps: the filter transmits a temperature signal through a temperature transmitter, the temperature is raised to 80-90°C via a heating device, the filter inlet valve and the clear liquid outlet valve are opened, and wait The processed wax oil enters the filter, the impurities are separated and intercepted by the filter element, and the clean wax oil is discharged into the next-level processing unit through the filter outlet. When the pressure transmitter feedbacks the inlet and outlet pressure difference to the set value (0.3 MPa) or reaches Set the upper limit of the filtering time (12 h), the filtering is terminated, and compressed nitrogen is introduced. When the feedback gas pressure of the pressure transmitter reaches the set value (0.1MPa) or reaches the set intake time (5min), the intake is stopped at this time , Open the slag discharge valve, and the filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com