Binary nitric acid nanometer molten salt heat transfer heat storage medium and preparation method thereof

A heat storage medium and molten salt technology, applied in chemical instruments and methods, heating devices, mechanical equipment, etc., can solve problems such as narrow operating temperature range, low thermal conductivity, poor thermal stability, etc., to increase thermal conductivity and heat transfer The effects of area, thermal conductivity improvement, and thermal conductivity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of nitric acid nano molten salt of the present invention has two kinds of options:

[0070] 1. Small-scale production for laboratory research can use the following steps:

[0071] Step 1: Compose a binary nitric acid molten salt system in proportion, put it into a vacuum heating furnace and heat to remove gas and water to make it into a molten state, and heat at a temperature 50-100°C above the phase transition temperature of the molten salt.

[0072] Step 2: Add the nanoparticles in proportion to the molten binary nitric acid nano-molten salt system in step (1), magnetically stir the molten mixture for 0.5-1h, keep it warm and ultrasonic for 0.5-2h, and cool naturally to obtain uniform and stable binary nitric acid nano molten salt.

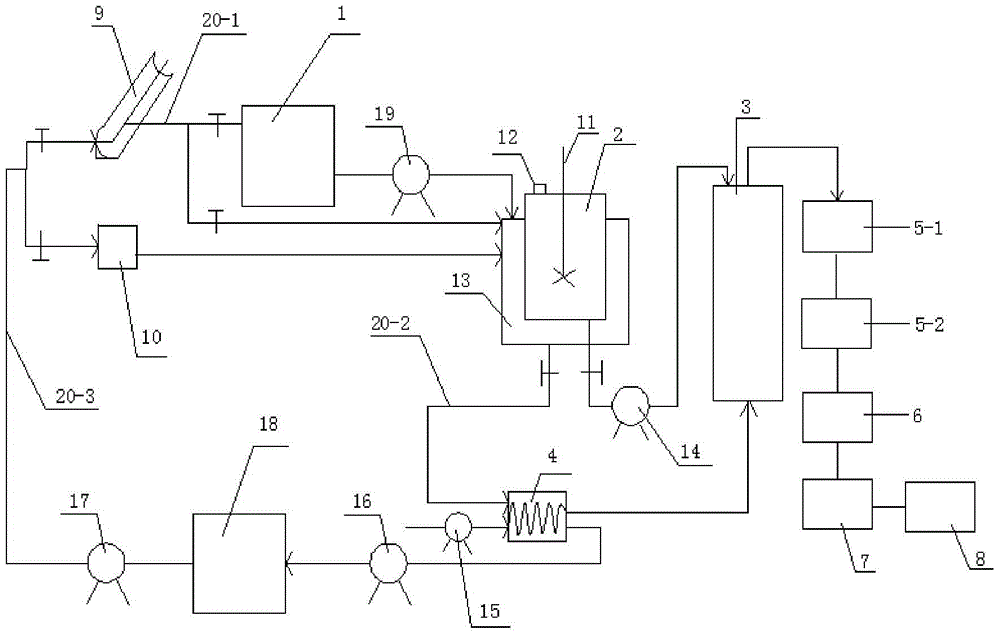

[0073] 2. Large-scale production preferably adopts the following processes and supporting molten salt preparation equipment:

[0074] Molten salt preparation equipment: the equipment includes a heat source device,...

Embodiment 1

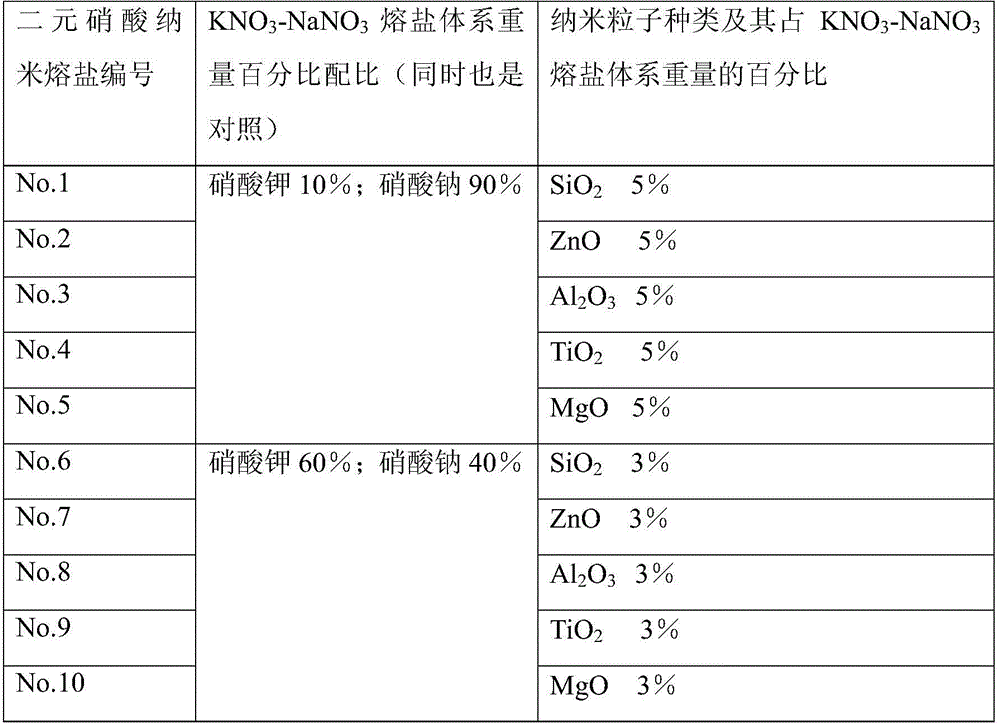

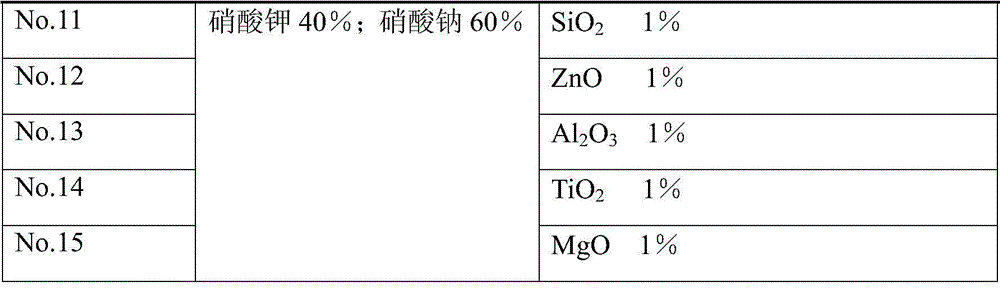

[0089] Example 1. Based on KNO 3 -NaNO 3 Preparation process and performance comparison of nanometer molten salt of binary nitrate system

[0090] Step 1. Composition of KNO in proportion 3 -NaNO 3 The molten salt system is put into a vacuum heating furnace and heated to remove gas and water to make it into a molten state, and the temperature is 50-100°C above the phase transition temperature of the molten salt.

[0091] Step 2. Add the nanoparticles into the melted binary nitric acid nano-molten salt system in step (1) in proportion, stir the molten mixture for 0.5-1h with magnetic force, keep it warm and ultrasonic for 0.5-2h, and cool naturally to obtain a uniform and stable binary nitric acid salt system. Nitric acid nano molten salt.

[0092] Step 3. Melting point test:

[0093] The general differential scanner DSC is used (scanning under normal pressure).

[0094] Step 4. Thermal Stability Test

[0095] The thermal stability test was carried out on the prepared bi...

Embodiment 2

[0113] Example 2 is based on KNO 3 -NaNO 2 Preparation process and performance comparison of nanometer molten salt of binary nitrate system

[0114] Step 1. Composition of KNO in proportion 3 -NaNO 2 For the molten salt system, heat and stir evenly and put it into a vacuum heating furnace to heat and degas and remove water to make it into a molten state. The heating temperature is 50-100°C above the phase transition temperature of the molten salt.

[0115] Step 2. Add the nanoparticles into the melted binary nitric acid nano-molten salt system in step (1) in proportion, stir the molten mixture for 0.5-1h with magnetic force, keep it warm and ultrasonic for 0.5-2h, and cool naturally to obtain a uniform and stable binary nitric acid salt system. Nitric acid nano molten salt.

[0116] Step 3. Melting point test:

[0117] The general differential scanner DSC is used (scanning under normal pressure).

[0118] Step 4. Thermal Stability Test

[0119] The thermal stability tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com