2.5 mm glass tempering process

A glass tempering and process technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large temperature drop, small glass thickness, uneven glass stress, etc. The effect of reducing the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

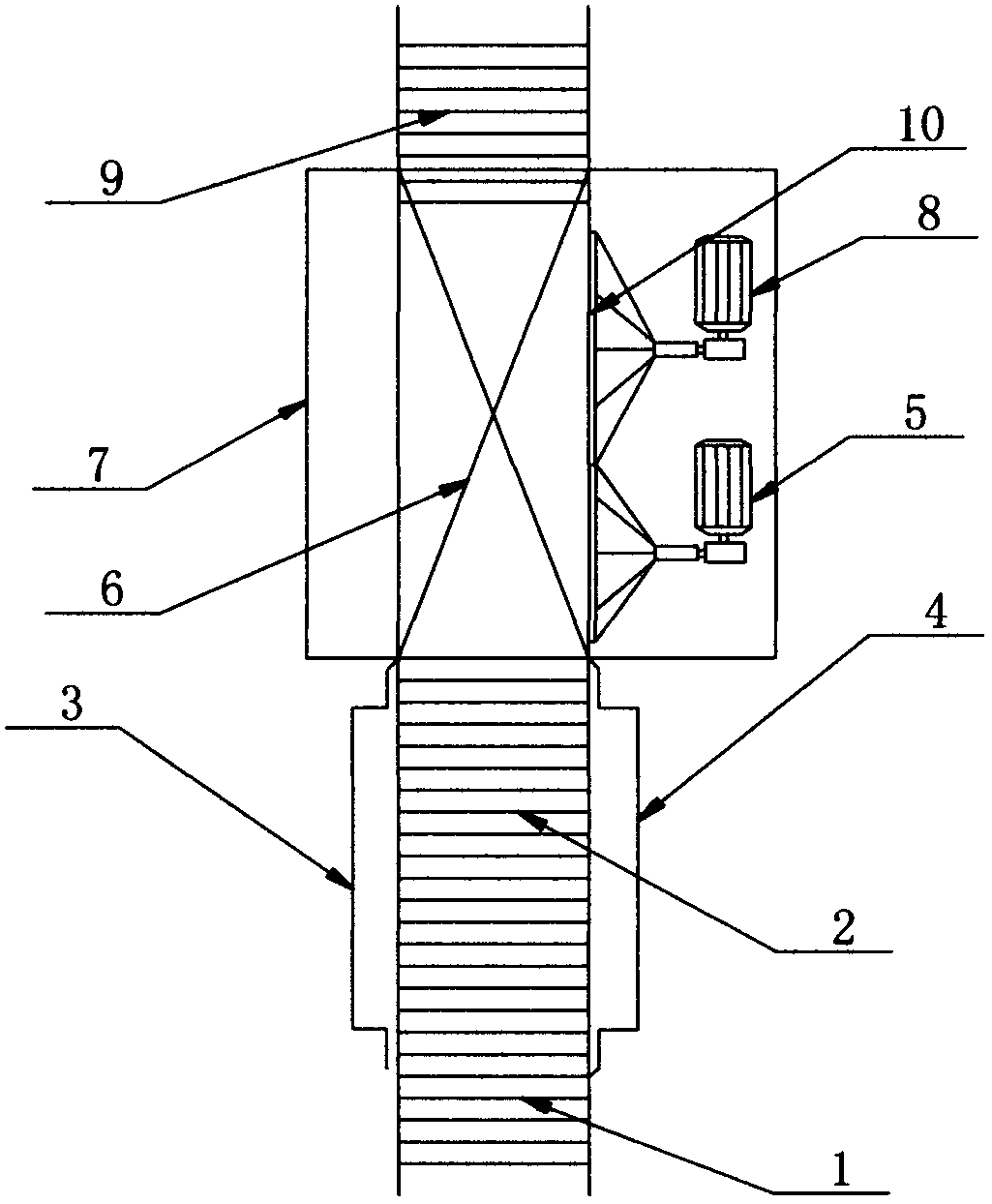

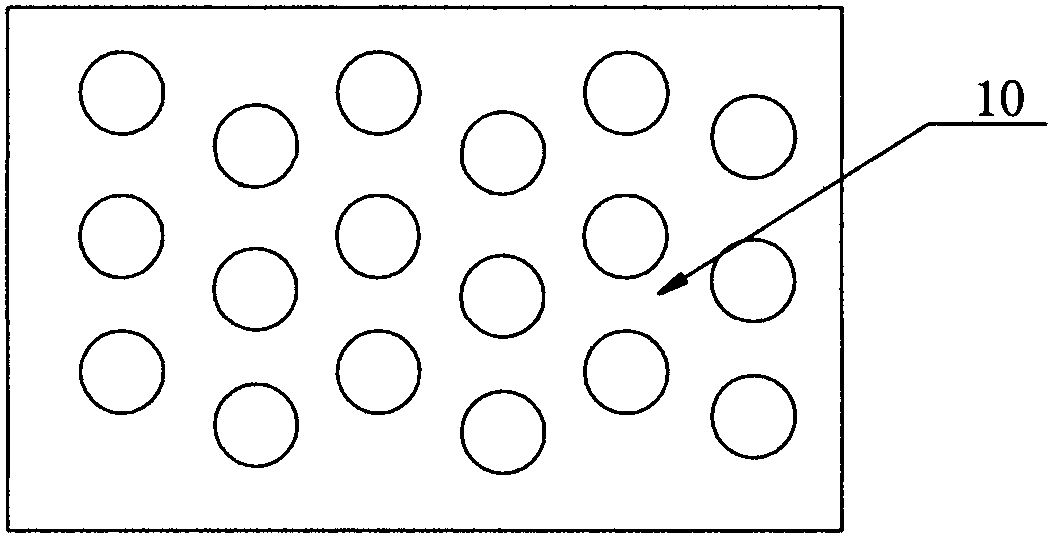

[0017] see Figure 1-Figure 2 , the specific embodiment adopts the following technical scheme: its tempering equipment includes upper sheet roller table 1, heating zone roller table 2, left air convection device 3, right air convection device 4, rapid cooling fan 5, tempering cooling part 6, Soundproof room 7, cooling fan 8, lower roller table 9, air nozzle 10, heating zone roller table 2 is installed on one side of upper sheet roller table 1, and left air convection device is installed on both sides of heating zone roller table 2 3. The air convection device 4 on the right side, the tempered cooling part 6 is set at the rear end of the roller table 2 in the heating zone, the soundproof room 7 is set on one side of the tempered cooling part 6, and the quenching fan 5 and cooling fan are respectively set on the other side 8. Several air nozzles 10 are installed on both the rapid cooling fan 5 and the cooling fan 8 , and the lower area roller table 9 is arranged at the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com