A kind of preparation method of nanoscale granular sodium cobaltate thermoelectric material

A thermoelectric material, a technology of sodium cobalt-like, applied in the directions of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of many process links and high production costs, and achieve reduced process links, low production costs, and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

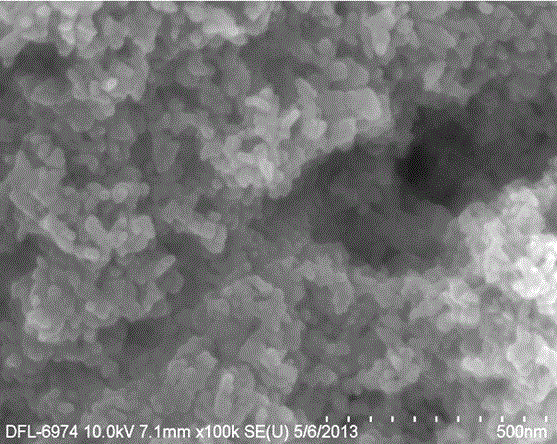

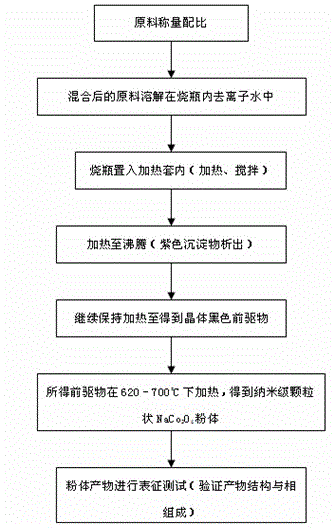

[0046] see image 3 , a method for manufacturing a nanoscale granular sodium cobaltate thermoelectric material, the method includes the following processes in sequence;

[0047] Preparation of the mixed solution: first analyze the pure NaNO 3 , Co(NO 3 ) 2 ·6H 2 O, urea is mixed uniformly, then dissolves in deionized water together, and stirs to prepare mixed solution; The NaNO 3 , Co(NO 3 ) 2 ·6H 2 The molar ratio of O, urea, and deionized water is 0.5–0.55:1:6–7:60–65, and NaNO 3 , Co(NO 3 ) 2 ·6H 2 The mass percent concentrations of O and urea are all greater than or equal to 99.9%;

[0048] Obtaining the precursor: First, continue heating and stirring the above mixed solution. When the mixed solution boils and produces purple precipitates, the self-propagating reaction begins. At this time, stop stirring and continue heating to keep the mixed solution in a boiling state. When the crystalline black precursor is used, the self-propagating combustion reaction ends...

Embodiment 2

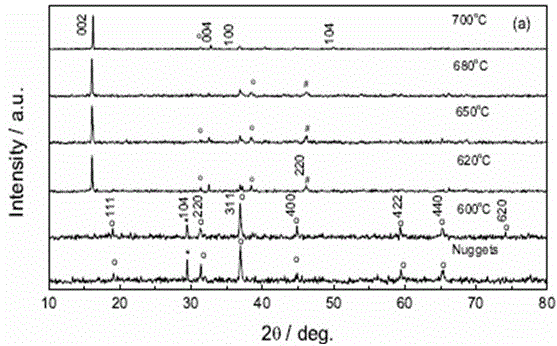

[0051] The basic content is the same as that of Example 1, except that in the preparation of the thermoelectric material: the heating temperature is 620° C., and the heating time is 100 min.

Embodiment 3

[0053] The basic content is the same as that of Example 1, except that in the preparation of the thermoelectric material: the heating temperature is 700° C., and the heating time is 80 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com