Centralized fountain solution purifying system

A purification system and dampening solution technology, applied in lithographic rotary printing machines, chemical instruments and methods, filtration circuits, etc., can solve problems such as easy contamination of dampening solution, failure to achieve expected results, and failure to achieve zero discharge , to achieve the effect of reducing labor costs, easy operation, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

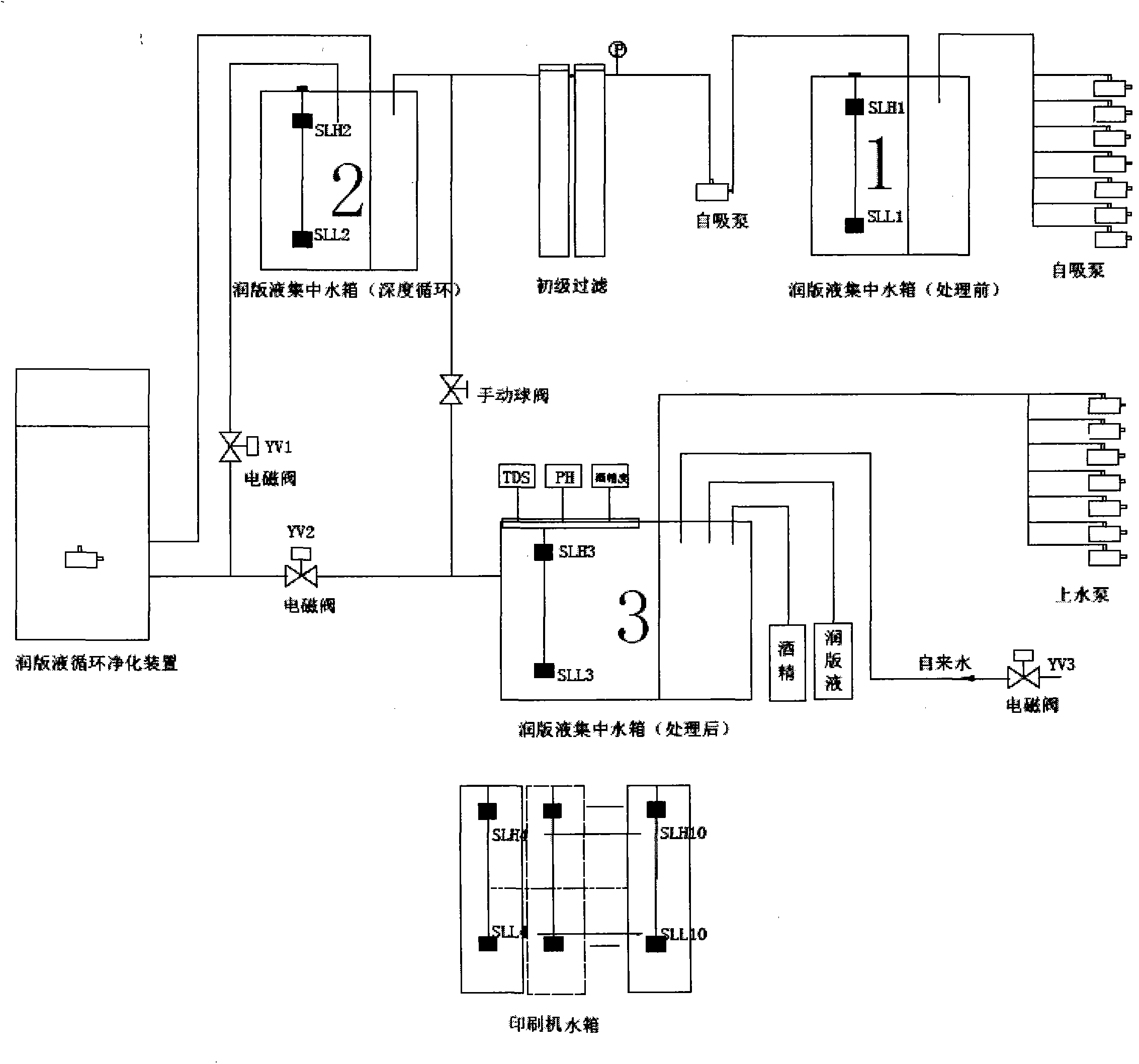

[0018] Such as figure 1 As shown, a fountain solution centralized purification system, including the No. 1 water tank (SLH1) connected to the water tank of the printing machine through a self-priming pump, the outlet of the No. 1 water tank is connected to the primary filter (purification) device through the self-priming pump The inlet is connected, the outlet of the primary filter device is connected with the inlet of No. 2 water tank (SLH2), and the outlet of the No. 2 water tank is connected with the outlet of the dampening solution circulation purification device to form a circulation loop and is provided with a solenoid valve YV1. The outlet of the deep circulation purification device is connected to the inlet of No. 3 water tank (SLH3) and is provided with a solenoid valve YV2. Float switch, the outlet of the No. 3 water tank is connected with the water tank of the printing machine through a booster pump (water pump).

[0019] The outlet of the No. 1 water tank is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com