Redstone cutting machine

The technology of a stone cutting machine and a frame is applied in the field of redstone cutting machines, which can solve the problems of low work efficiency, large labor consumption, low work efficiency, etc., and achieve the effects of simple structure, good cutting effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

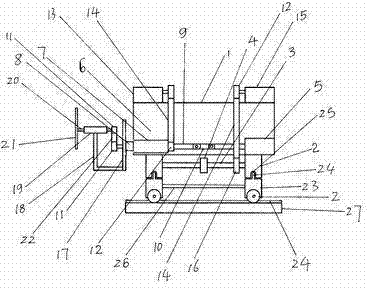

[0006] control figure 1 It can be seen that a redstone cutting machine includes a frame 1, two running wheels 2 are symmetrically arranged on both sides of the bottom of the frame 1, and the two symmetrical running wheels are connected by a connecting shaft 3, and each connecting shaft There is a connecting gear 4, and a chain is arranged between the two connecting gears (not shown in the figure). 6, the rotating shaft assembly includes a housing 7, in which a large rotating shaft 8 and a small rotating shaft 9 are arranged, the large rotating shaft is hollow, the small rotating shaft is in the hollow of the large rotating shaft, the right end of the small rotating shaft passes through the ten thousand Connect the rotating shaft of the first motor to the coupling shaft 10, the left end of the small rotating shaft is provided with a pulley 11, the right end of the large rotating shaft is provided with a gear 12, and the left side of the top of the frame is provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com