Automatic component detecting and grading machine

A fully automatic, binning machine technology, applied in sorting and other directions, can solve the problems of less binning, low detection efficiency, and single product applicability, and achieve the effect of freely controlling the number of bins and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

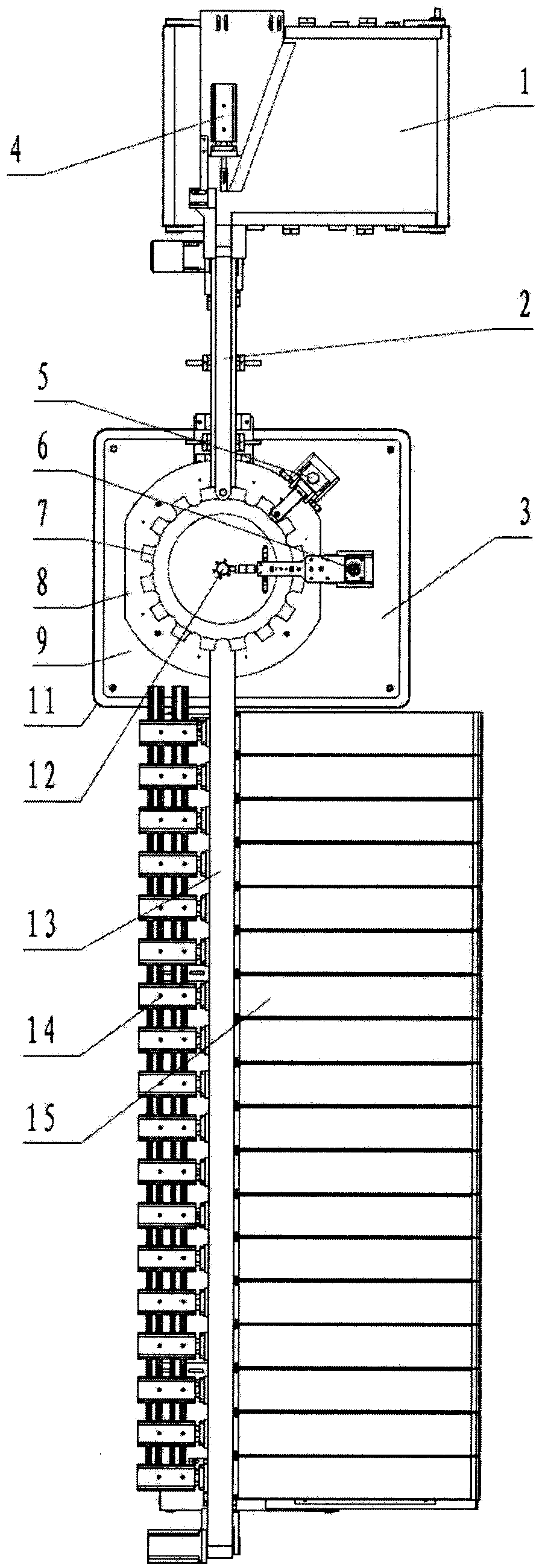

[0022] According to attached figure 1 As shown, a fully automatic parts detection and classification machine mainly includes: feeding platform conveyor belt 1, feeding platform cylinder 4, feeding conveyor belt 2, measuring platform 3, dividing platform conveyor belt 13, dividing cylinder 14, Binning box 15.

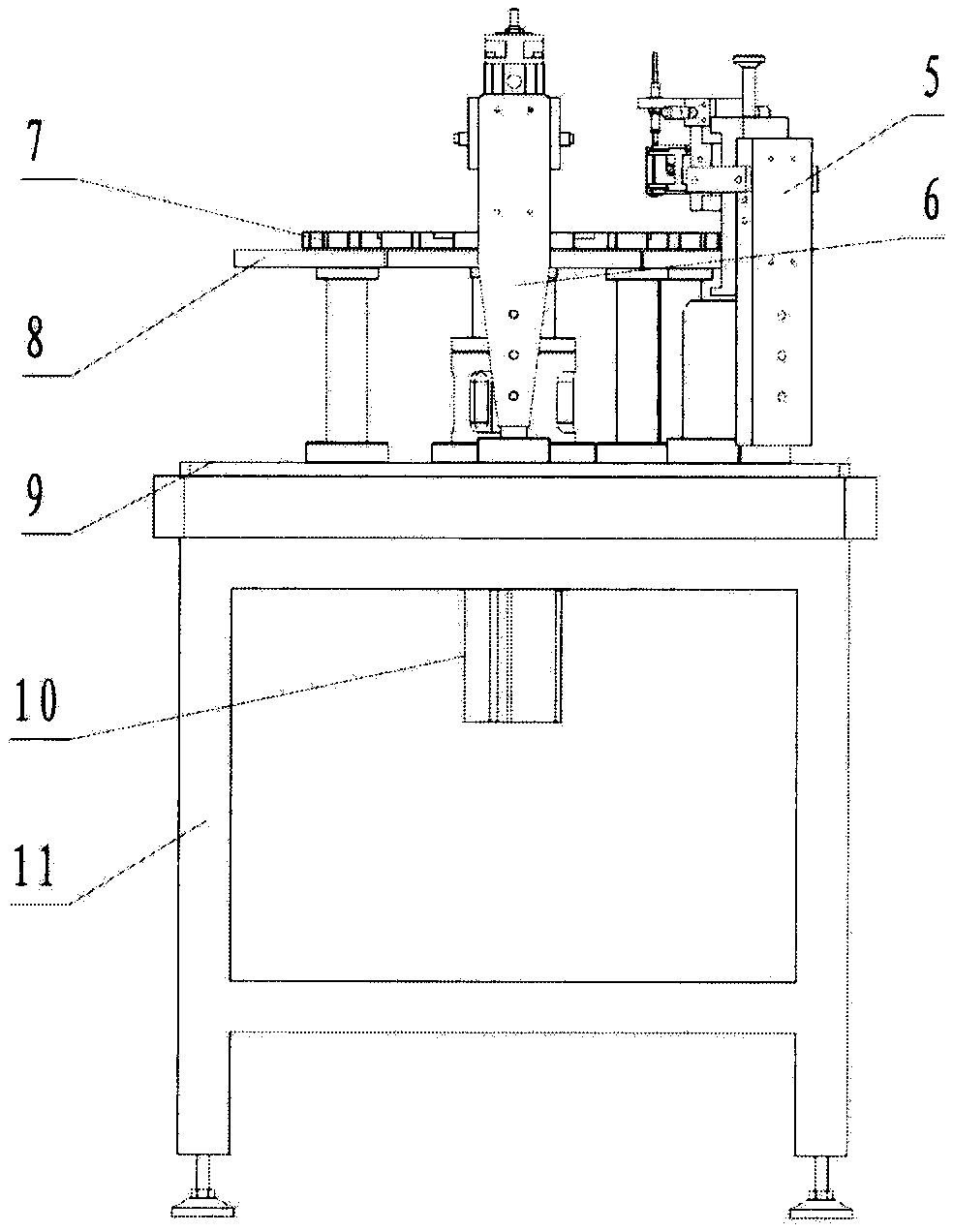

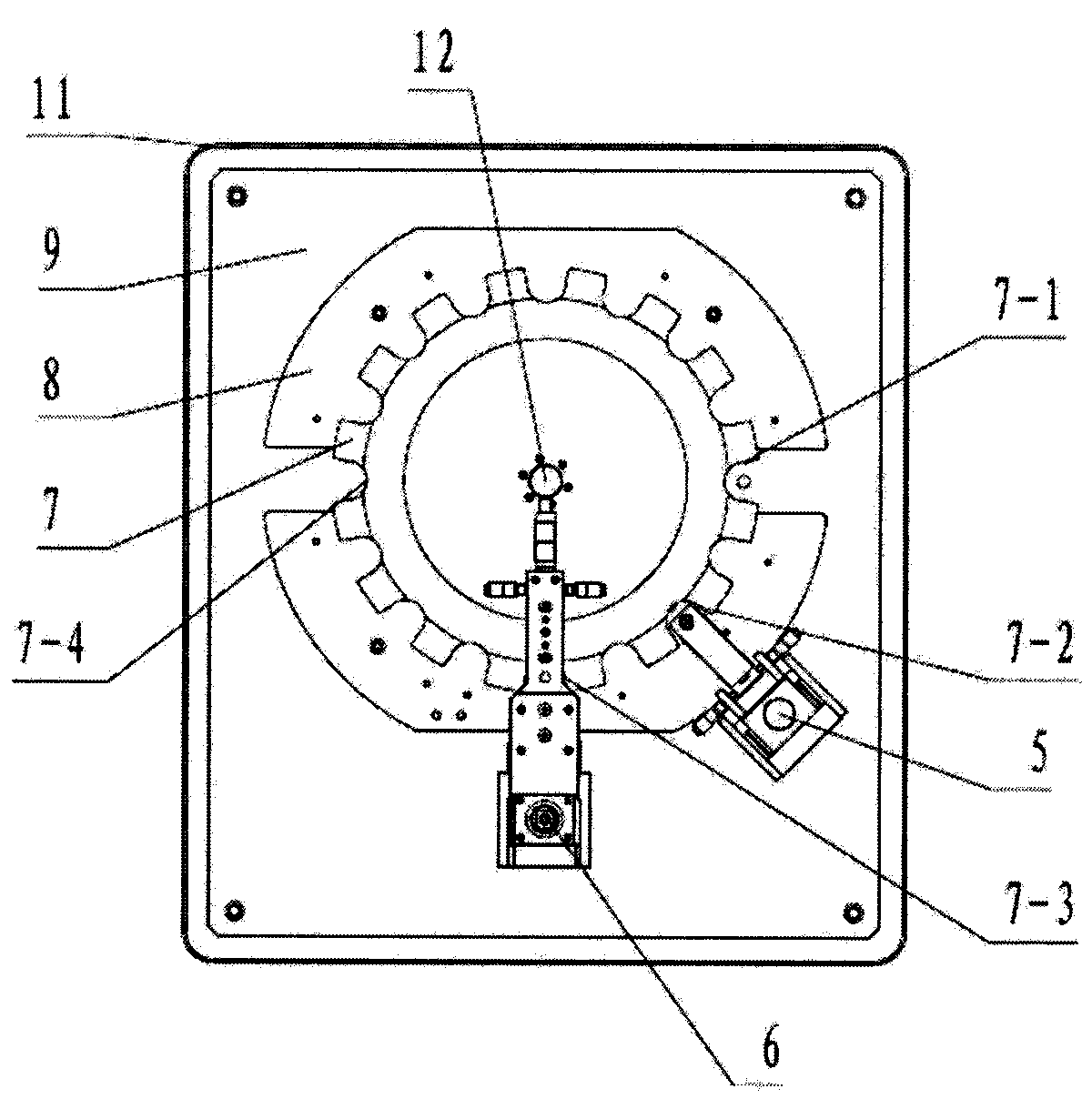

[0023] According to attached figure 2 , 3 As shown, the measuring platform 3 includes: a height measuring mechanism 5, an outer diameter measuring mechanism 6, a material tray 7, a measuring platform bottom plate 8, a measuring platform table top 9, a motor 10, a measuring platform frame 11, a measuring platform drive shaft 12, and a measuring platform The table 9 is installed on the measuring table frame 11, the measuring table bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com