Optical converter for high luminances

A converter and high-brightness technology, applied in the field of optical converters, can solve problems such as light share decline, and achieve the effects of small emission spots, good light confinement, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

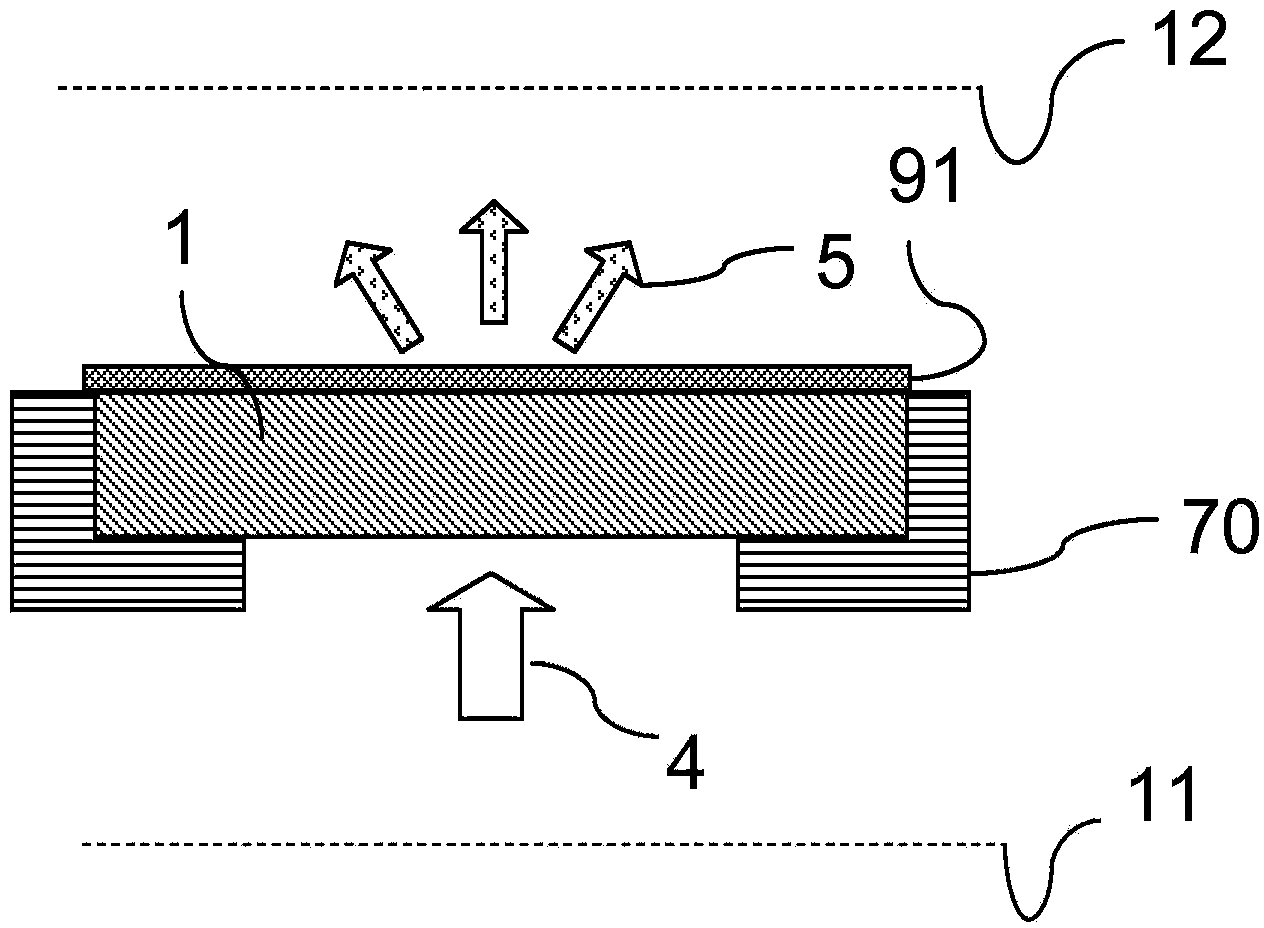

[0081] An exemplary embodiment of the invention is subsequently described with the aid of these figures.

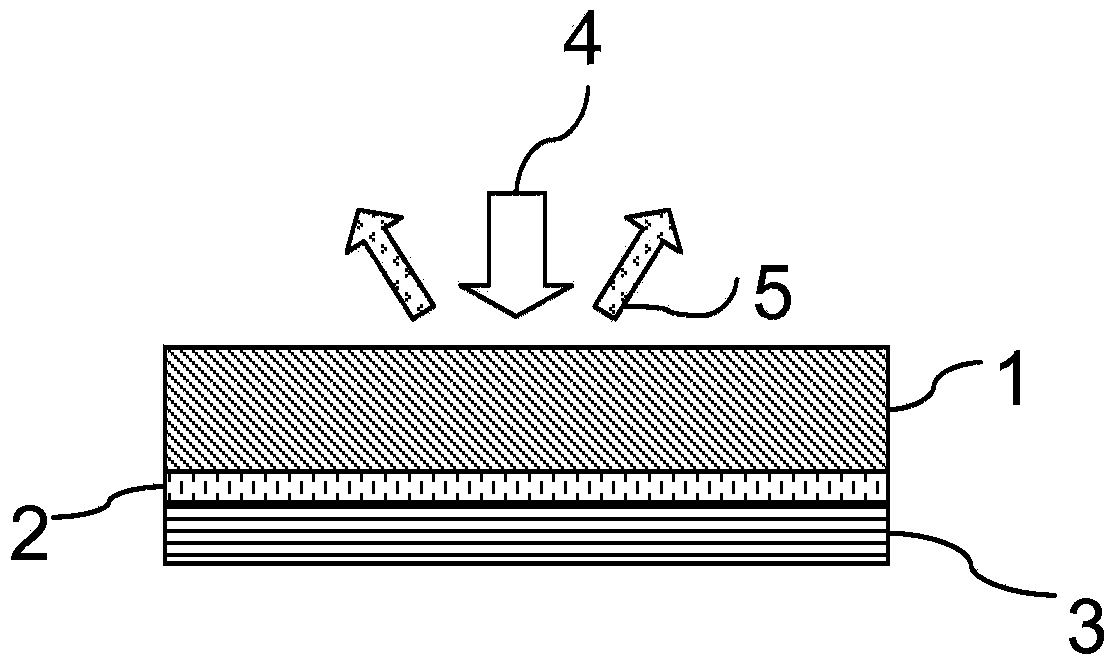

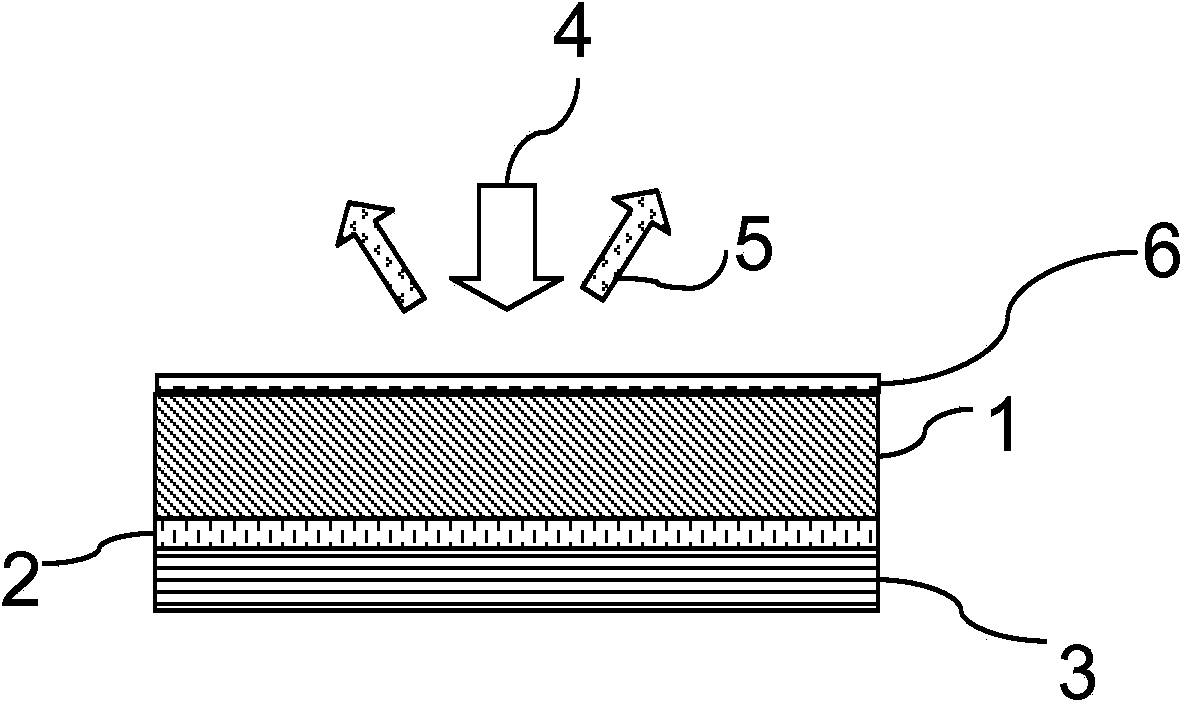

[0082] As a first example, figure 1 A side view showing the schematic structure of a diffusely operating converter.

[0083] The converter comprises a converter body 1 designed as an opto-ceramic and a mirror 3 , which are connected to one another via an adhesive layer 2 . The converter material (optoceramic) is a doped YAG ceramic or LuAG ceramic and forms a grain structure with strong scattering.

[0084] From above, i.e. from the excitation side, blue excitation light 4 of high power density (i.e. with a small beam cross section) falls onto the excitation side of the converter body 1 and, after entering the optoceramic, is converted to produce a long wavelength light 5 and is output outwards by scattering, as shown by the arrows.

[0085] The adhesive layer 2 has, for example, a thickness d of 10 μm Kleb . The mirror 3 reflects the excitation light 4 into the opto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com