Circuit board

A circuit board and line technology, applied in the direction of printed circuit components, etc., can solve the problems of lower transmission quality, impedance mismatch, low impedance, etc., and achieve the effect of improving high-frequency transmission quality and consistent impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

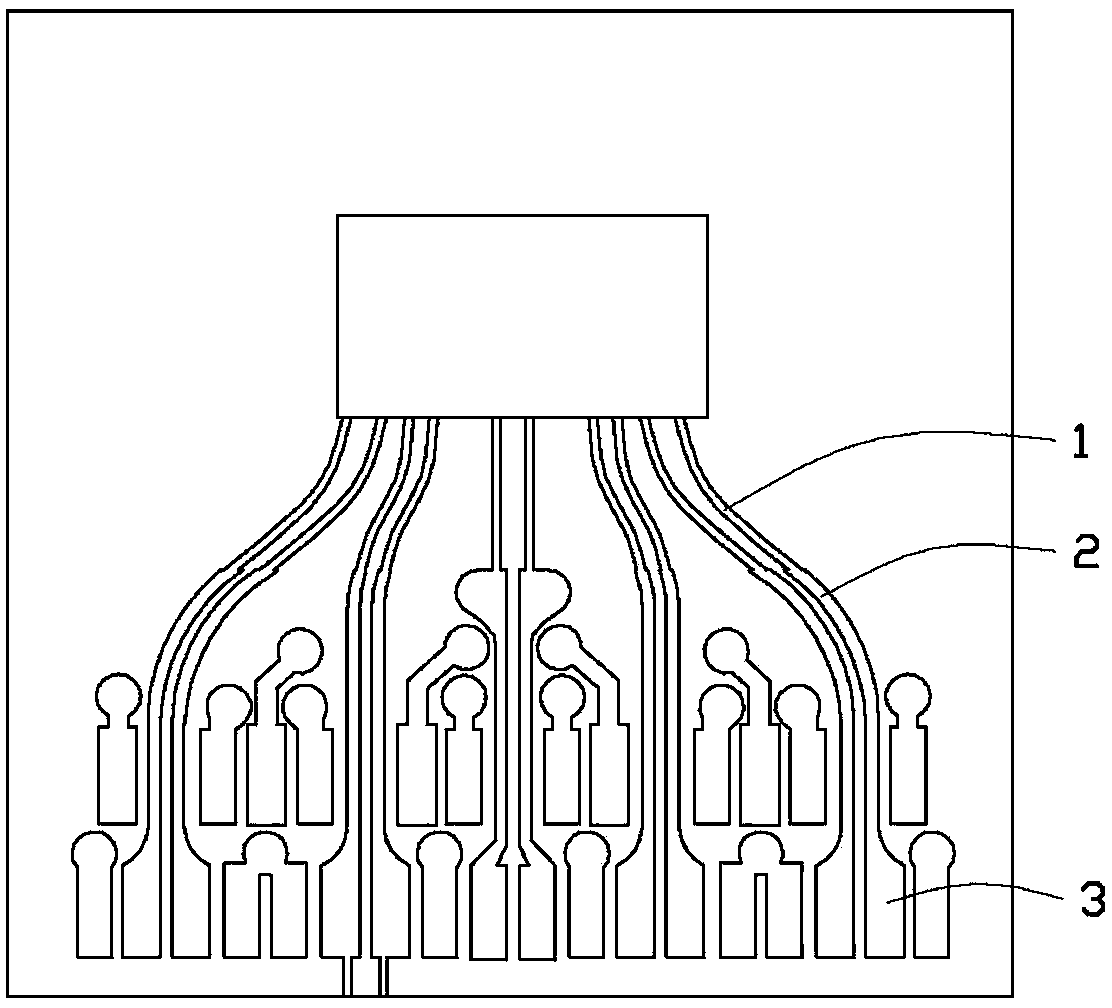

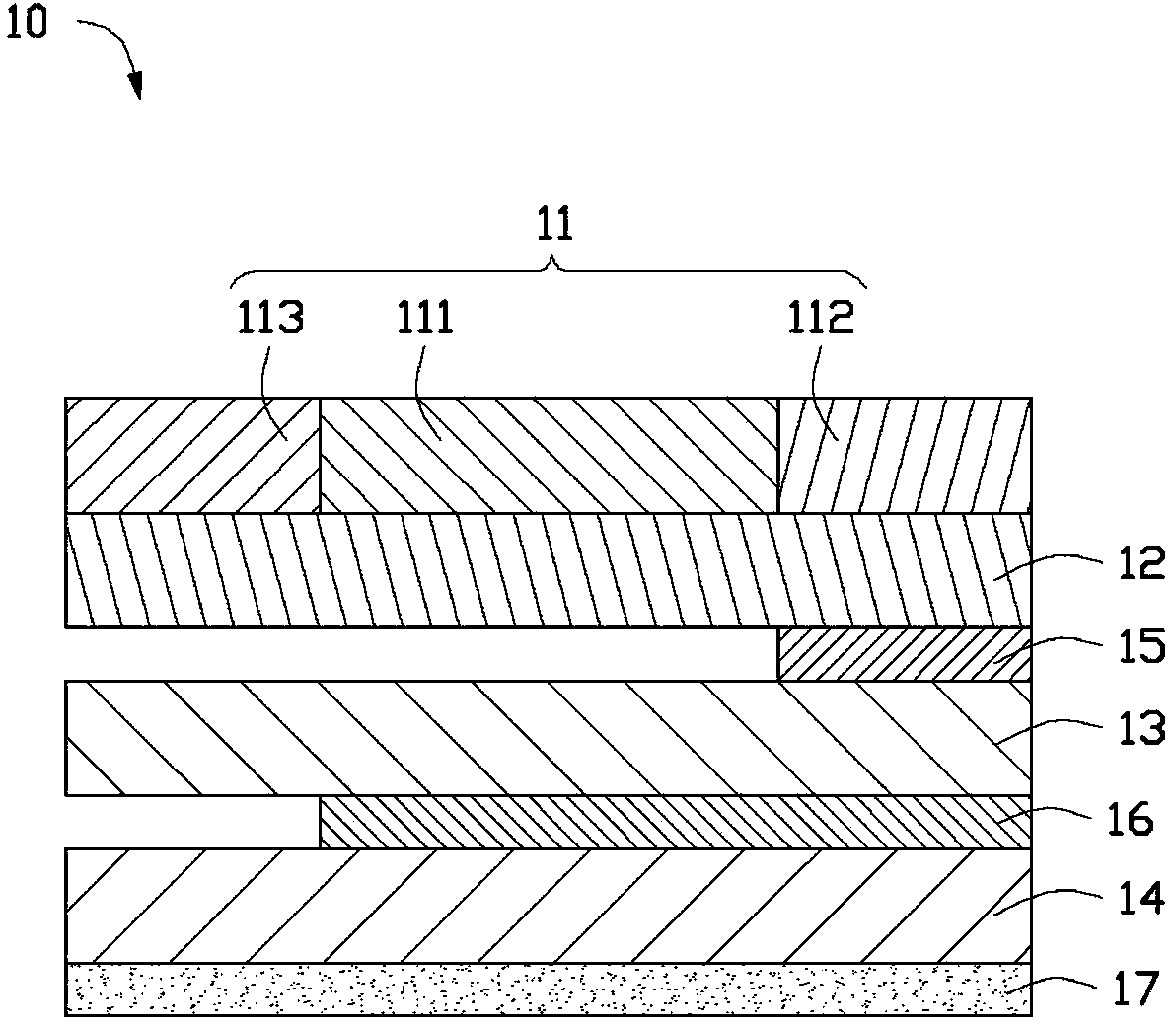

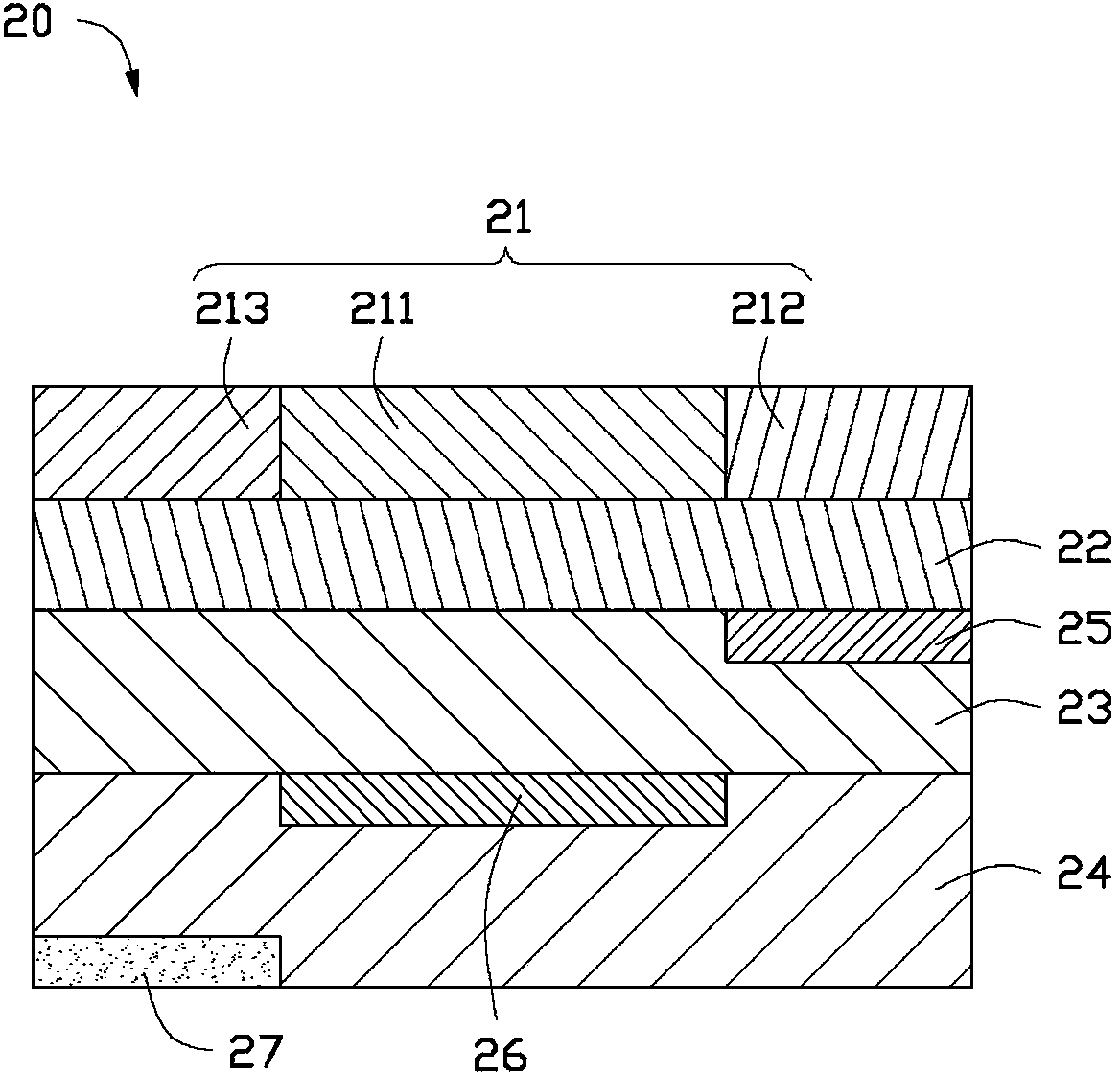

[0014] see figure 2 The circuit board 10 provided by the first embodiment of the present invention includes a signal wiring layer 11, a first dielectric layer 12, a second dielectric layer 13, a third dielectric layer 14, a first ground layer 15, a second ground layer 16 and the third ground layer 17, the first dielectric layer 12, the first ground layer 15, the second dielectric layer 13, the second ground layer 16, the third dielectric layer 14 and the third ground layer 17 gradually move away from the signal traces Line layer 11.

[0015] In practical applications, the circuit board 10 also includes a conductive layer, etc., for simplicity, figure 1 Only the signal wiring layer 11, the first dielectric layer 12, the second dielectric layer 13, the third dielectric layer 14, the first ground layer 15, the second ground layer 16 and the The third ground layer 17 .

[0016] The signal trace layer 11 and the first ground layer 15 are respectively located on two opposite sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com