Lamination device and lamination method for stator core of direct drive permanent magnet generator

A permanent magnet generator and stator iron core technology, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of iron core insulation failure, conduction, difficulty, etc., to ensure the lamination coefficient, the appearance quality, and the insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

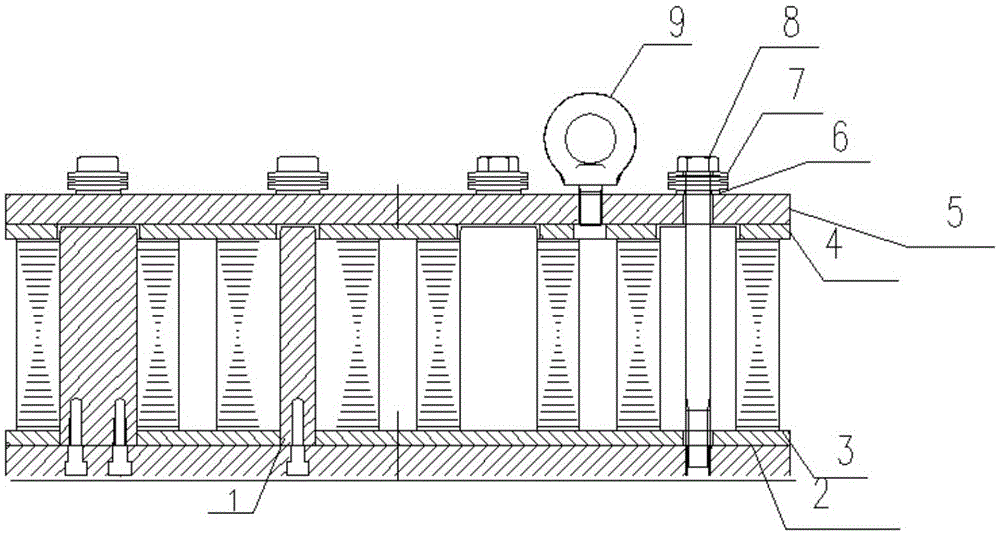

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems to be solved by the present invention, technical solutions and beneficial effects clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention. Invention does not limit the present invention.

[0016] First, the material is selected as a non-oriented magnetic steel sheet, and the steel sheet is a silicon steel sheet with a self-adhesive hot-pressed insulating coating on the surface;

[0017] Check the flatness of the self-adhesive stator core, and control the flatness below 1.5mm;

[0018] Carefully check the surface of the stator core before bonding to avoid oil and dust falling into it;

[0019] Set dovetail slots in quarters at the position corresponding to the groove shape on the upper pressing plate of the stator stack, and set slot-like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com