A high-power motor heat dissipation structure

A motor cooling and high-power technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the normal operation of electronic components, poor heat dissipation effect, etc., to achieve the effect of tight connection, good heat dissipation effect, and not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

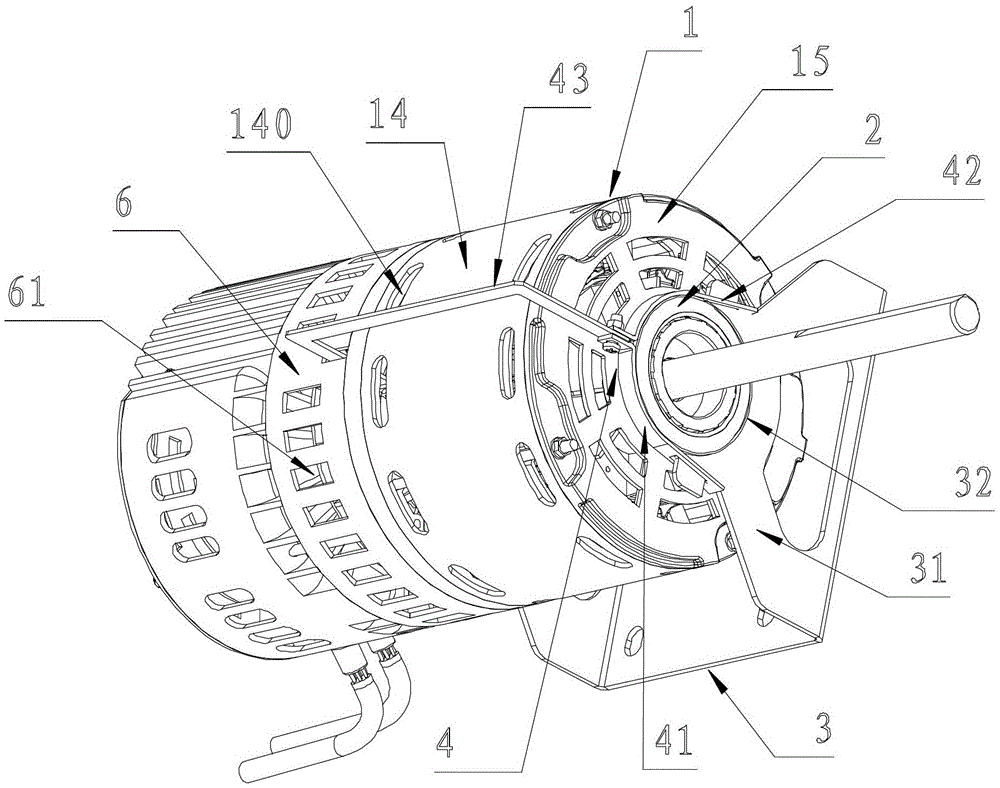

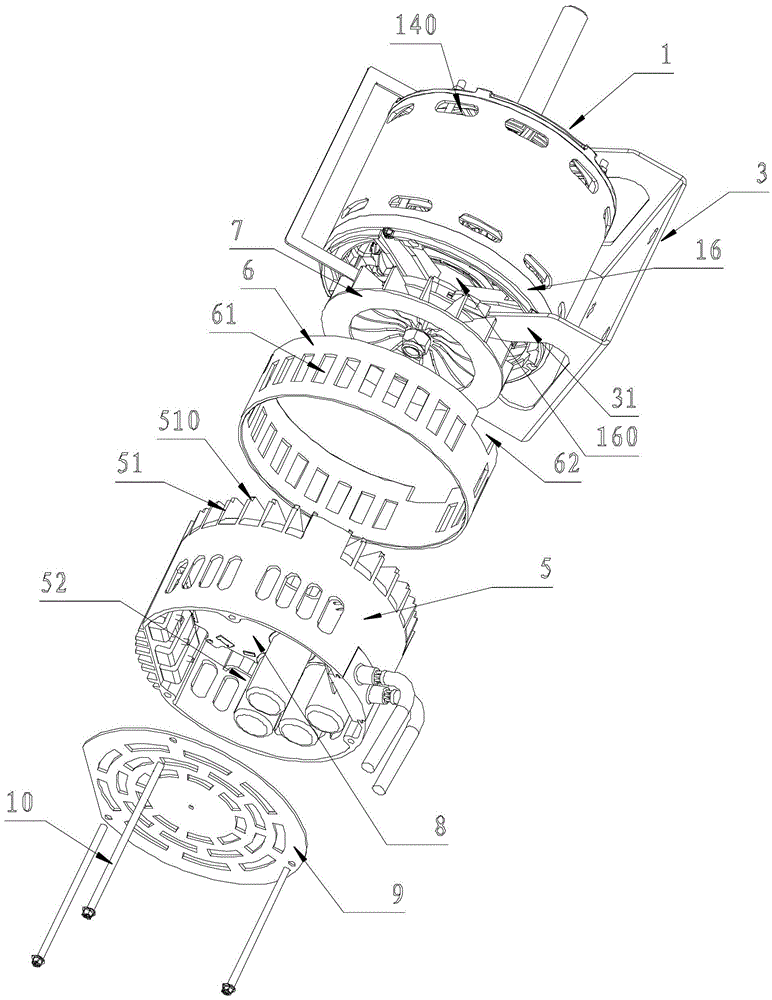

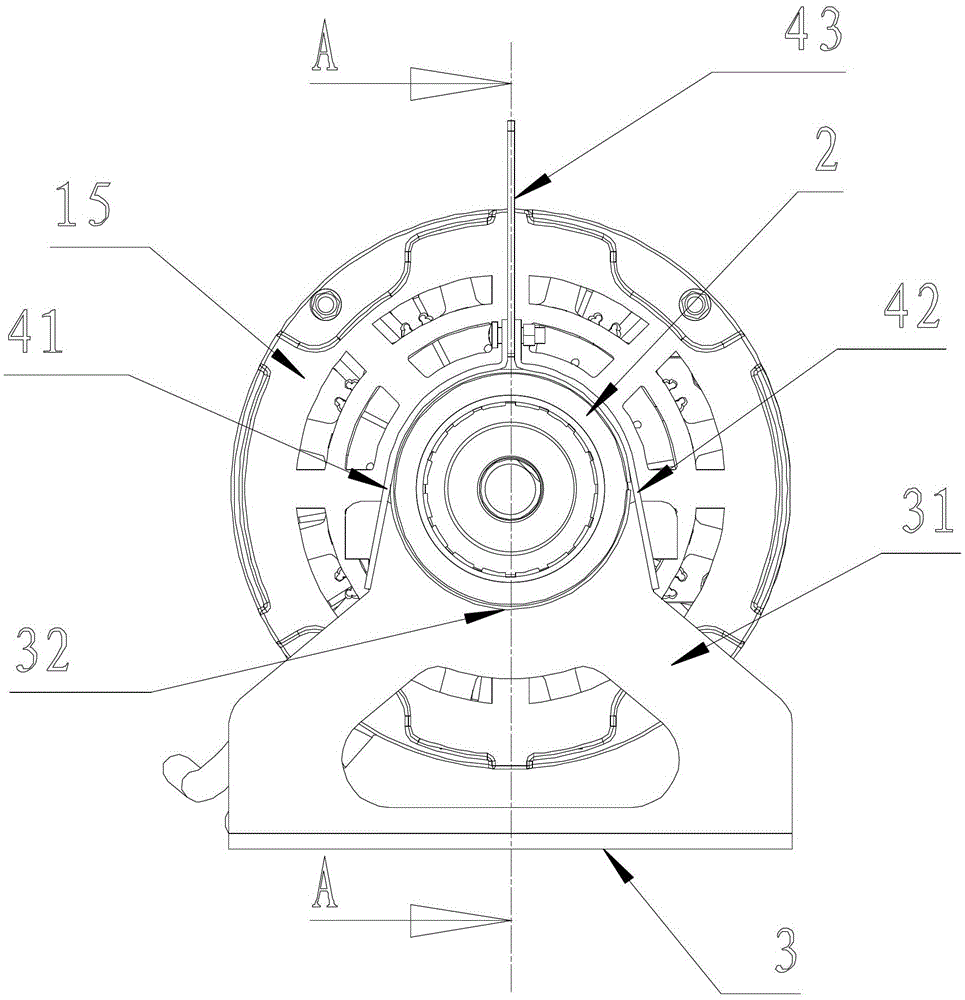

[0028] Embodiment one: if Figure 1 to Figure 6 As shown, the present invention is a high-power motor heat dissipation structure, including a motor body 1, a shock absorbing ring 2, a mounting bracket 3, a locking device 4 and a control box 5, and the shock absorbing ring 2 is installed at both ends of the motor body 1, And the bottom of the shock absorbing ring 2 is supported on the mounting bracket 3, and the locking device 4 locks the shock absorbing ring 2 on the mounting bracket 3. It also includes a connecting casing 6, and one end of the connecting casing 6 is installed and connected to the motor body 1. At the bottom, the other end of the connection casing 6 is installed and connected to the top of the control box 5 , and a number of cooling holes 61 are opened on the side wall of the connection casing 6 .

Embodiment 2

[0029] Embodiment 2: On the basis of Embodiment 1, the following technical features are added: the top surface of the control box 5 protrudes from a number of heat dissipation plates 51, and the outer edge of the heat dissipation plate 51 is provided with heat dissipation plate steps 510, and the other end connected to the casing 6 is covered with a heat dissipation plate. Board steps 510 up.

Embodiment 3

[0030] Embodiment 3: On the basis of Embodiment 2, the following technical features are added: a number of heat dissipation plates 51 are radial, and the outer ends of two adjacent heat dissipation plates 51 form air inlets 100, and a second air inlet 100 is formed between two adjacent heat dissipation plates 51. Yifeng Road 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com