A siw-based hermetic packaging structure for millimeter-wave chips

A packaging structure and millimeter-wave technology, which is applied in waveguides, electrical components, waveguide-type devices, etc., can solve the problems of large millimeter-wave losses and achieve great economic benefits, low cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

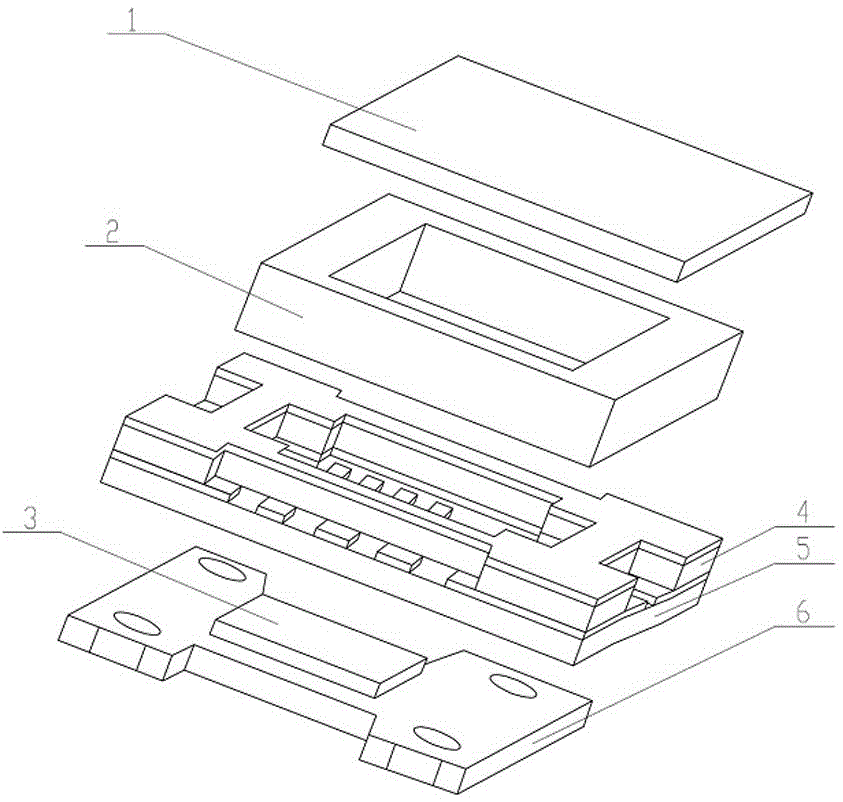

[0019] Depend on figure 1 It can be seen from the figure that an SIW-based millimeter-wave chip hermetic packaging structure includes a base 6 , an LTCC substrate, a sealing ring 2 and a cover plate 1 which are sealed and connected sequentially from bottom to top.

[0020] The base 6 of the package is made of tungsten copper material. The thermal expansion coefficient of tungsten copper is the same as that of GaAs and other microwave integrated circuits, and the heat dissipation performance is relatively good, which can improve the heat conduction and thermal matching of the power amplifier circuit of the millimeter wave chip, and improve the power amplifier circuit. Efficiency, improve the reliability of millimeter wave chip work.

[0021] The center of the base 6 is provided with a boss 3 for sintering millimeter-wave chips, and the height of the base 6 other than the boss 3 is lower than that of the boss 3; mounting holes can also be provided around the base 6 for easy inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com