Molecular imprinting microfluidics sensor based on double-annular-fiber-core optical fiber and double-annular-fiber-core optical fiber

A molecular imprinting and microfluidic technology, applied in multi-layer core/clad optical fibers, clad optical fibers, instruments, etc., can solve the problems of poor interferometer structure selectivity, complex system structure, large volume, etc., and achieve a simple structure. , compact structure, high detection sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

[0025] The molecularly imprinted optical fiber online sensor based on the Mach-Zehnder type optical fiber interferometer of the present invention is realized in this way: an optical fiber containing a double annular core is used to connect the interference optical path and perform sensing, and its features mainly include the following:

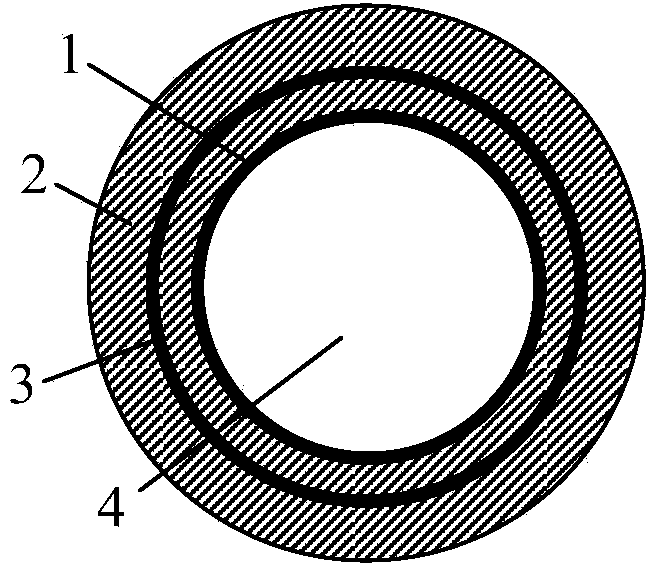

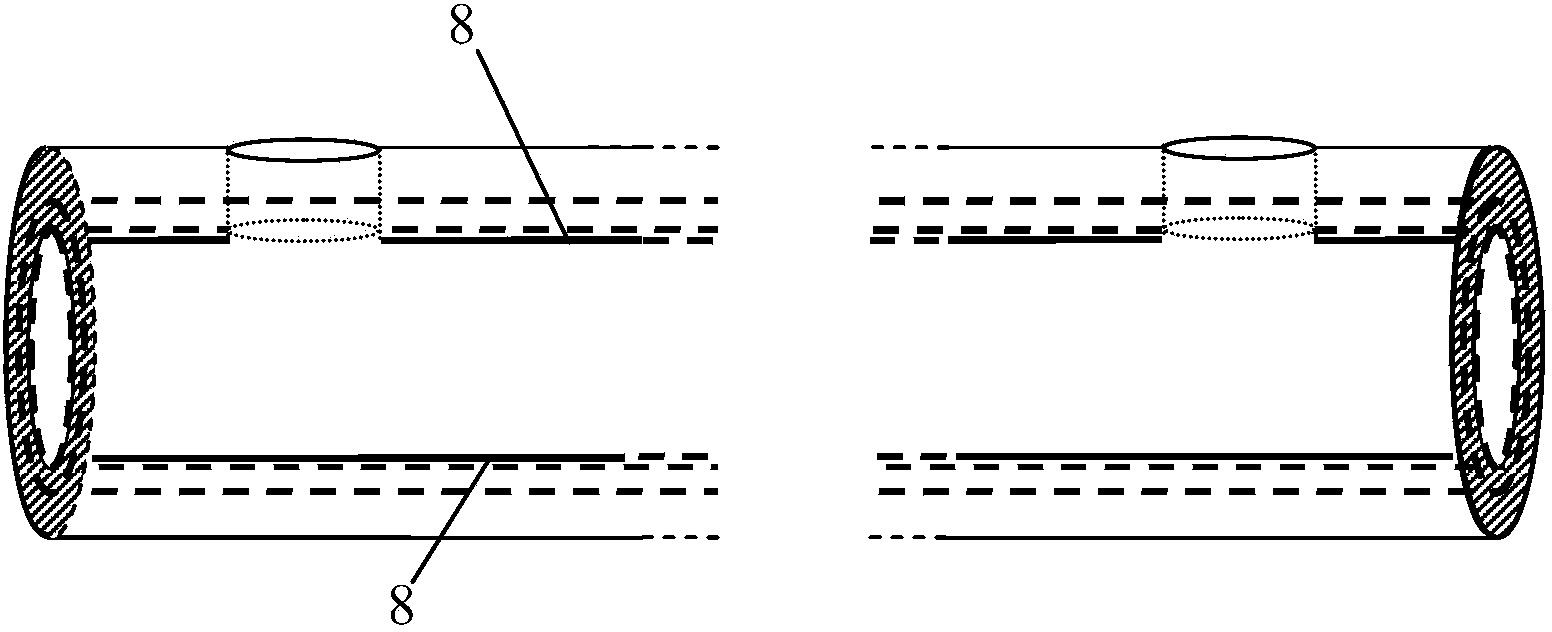

[0026] combine figure 1 , The main feature of the structure of the end face of the double-ring core optical fiber for sensing is that it has a double-ring core and a channel structure, and the core has a large specific surface area. The fiber core [1] is located on the inner surface of the annular cladding [2], and the fiber core [3] is located inside the annular cladding [2]. Such as figure 2 As shown, the surface of the microfluidic channel[4] utilizes CO 2 The laser opens two microports, in which the micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com