Online gas tightness detection device and method for fuel cell stack

A fuel cell stack and detection device technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and measuring the rate of increase and deceleration of fluid, etc., which can solve problems such as messy pipelines, high cost of seals, and reduced work efficiency. , to achieve the effect of simplifying the air tightness testing operation, reducing the loss of seals and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with embodiment:

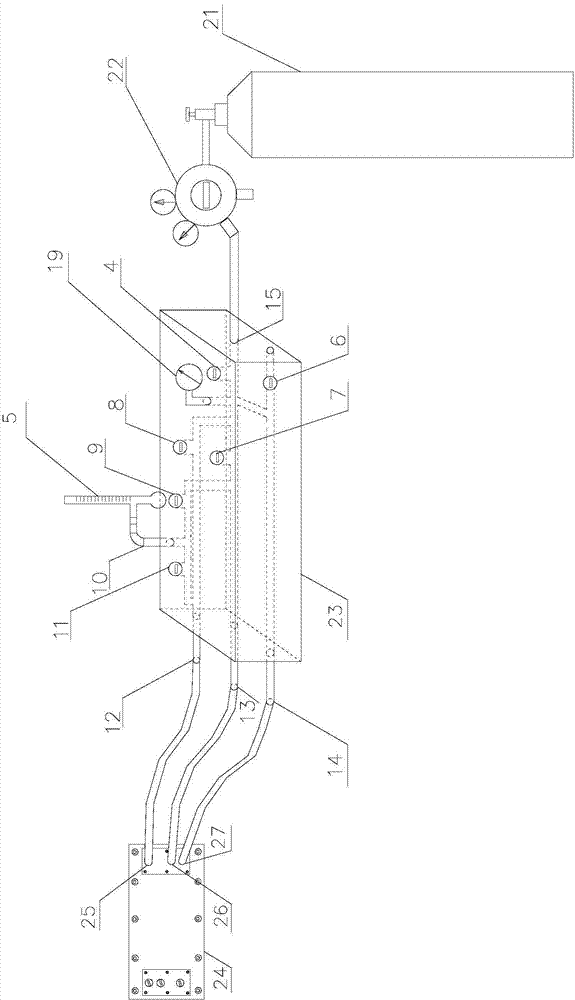

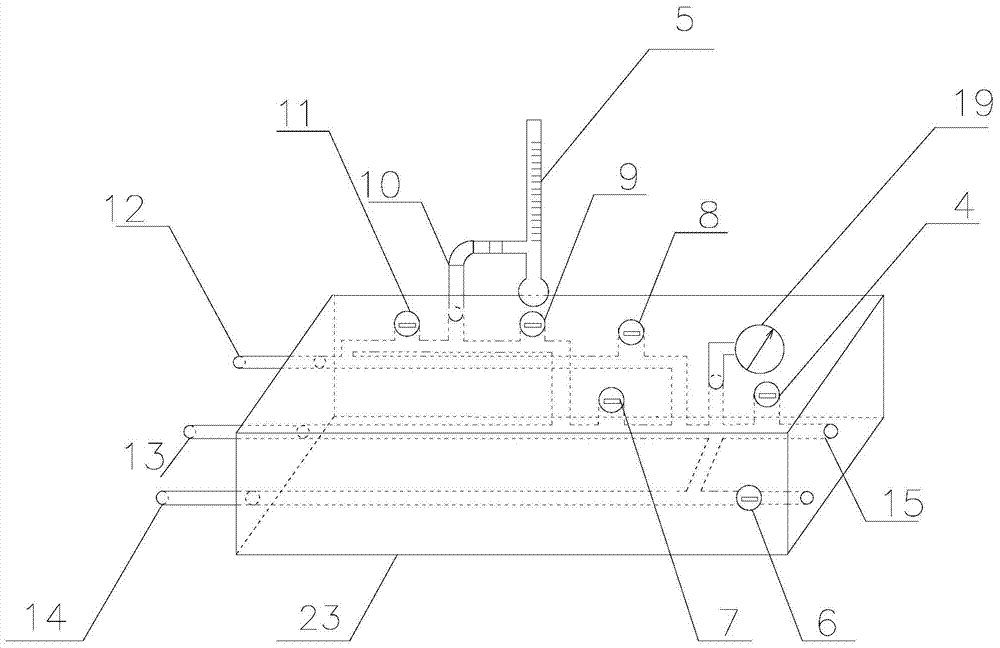

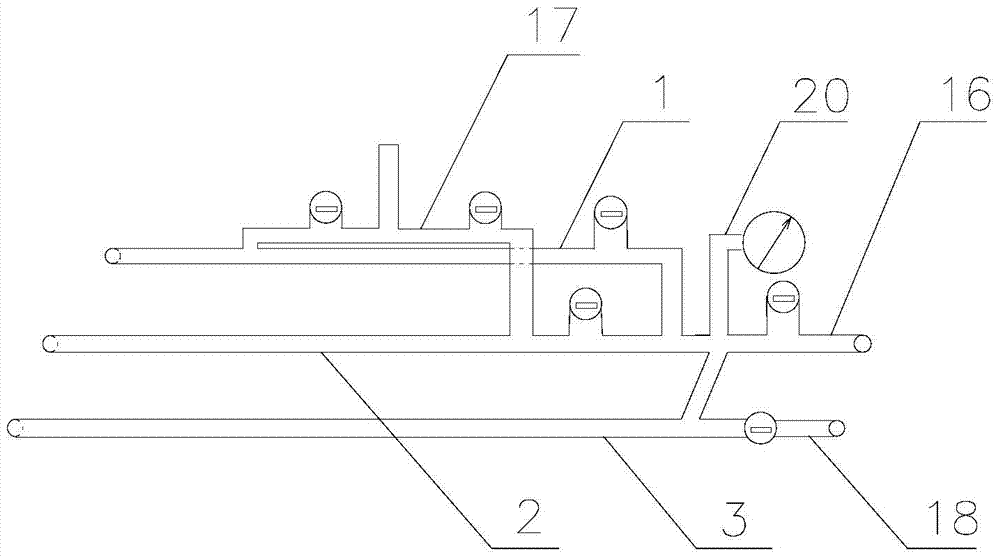

[0031] Such as Figure 1 to Figure 3As shown, this embodiment discloses an online airtightness detection device for a fuel cell stack, including a pressure gauge and a gas leakage rate tester, and is characterized in that it also includes a convenient airtightness test box 23, and the airtightness is conveniently One end of the test box 23 is provided with an air source inlet 15, and the air source inlet 15 is the port of the total air pipe 16, and the total air pipe 16 is provided with a pressure gauge interface 20, between the air source inlet 15 and the pressure gauge interface 20 A main air valve 4 is installed on the pipeline, and the end of the main air pipe 16 away from the inlet of the gas source is divided into three branch pipes: pipe I1, pipe II2 and pipe III3, and the ends of pipe I1, pipe II2 and pipe III3 away from the main air pipe are respectively Interface I12, interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com