Linear laser scanning three-dimensional contour measuring method and device

A technology of three-dimensional profile and measurement method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting measurement accuracy and efficiency, objects cannot move freely, increase instability, etc., and achieve accurate and fast measurement and simple structure , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

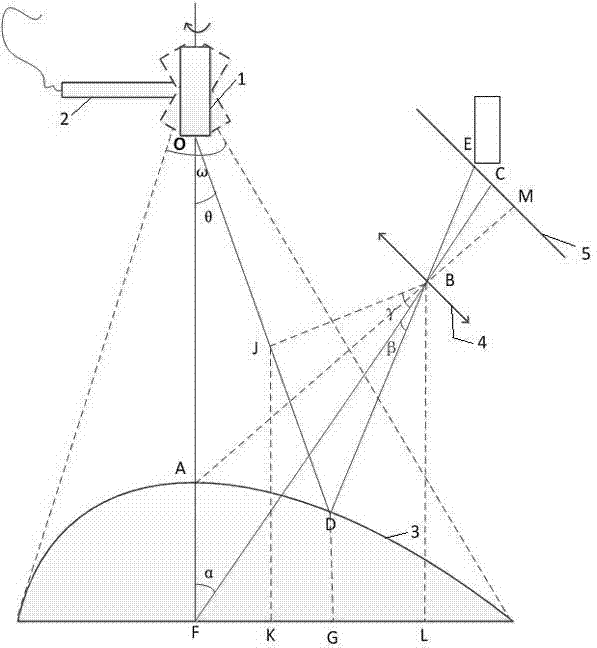

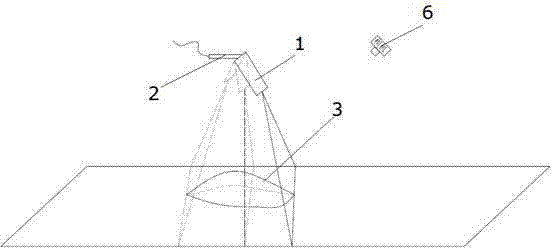

[0024] Such as figure 1 As shown, the object 3 is placed on the horizontal reference plane, and the word-line laser 1 swings under the control of the magnetostrictive micro-displacement controller 2 to form a scanning surface for the detected object 3. The swing angle ω is determined by the size of the object 3 It is determined that the selection principle of the oscillating angle is to ensure that the word-line laser 1 completely scans the outline of the detected object 3 . During the scanning process, the device obtains the height information of each contour point on the surface of the object 3 to reconstruct the three-dimensional surface contour of the object 3 .

[0025] Specifically, as figure 1 As shown, assuming that the ray OAF perpendicular to the horizontal reference plane is diffusely reflected by the horizontal reference pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com