Hydraulic oil tank liquid level and density alarming device

A technology of hydraulic oil tank and alarm device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, fluid pressure actuation system components, etc. components and other issues, to achieve the effect of small size, relatively low cost, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

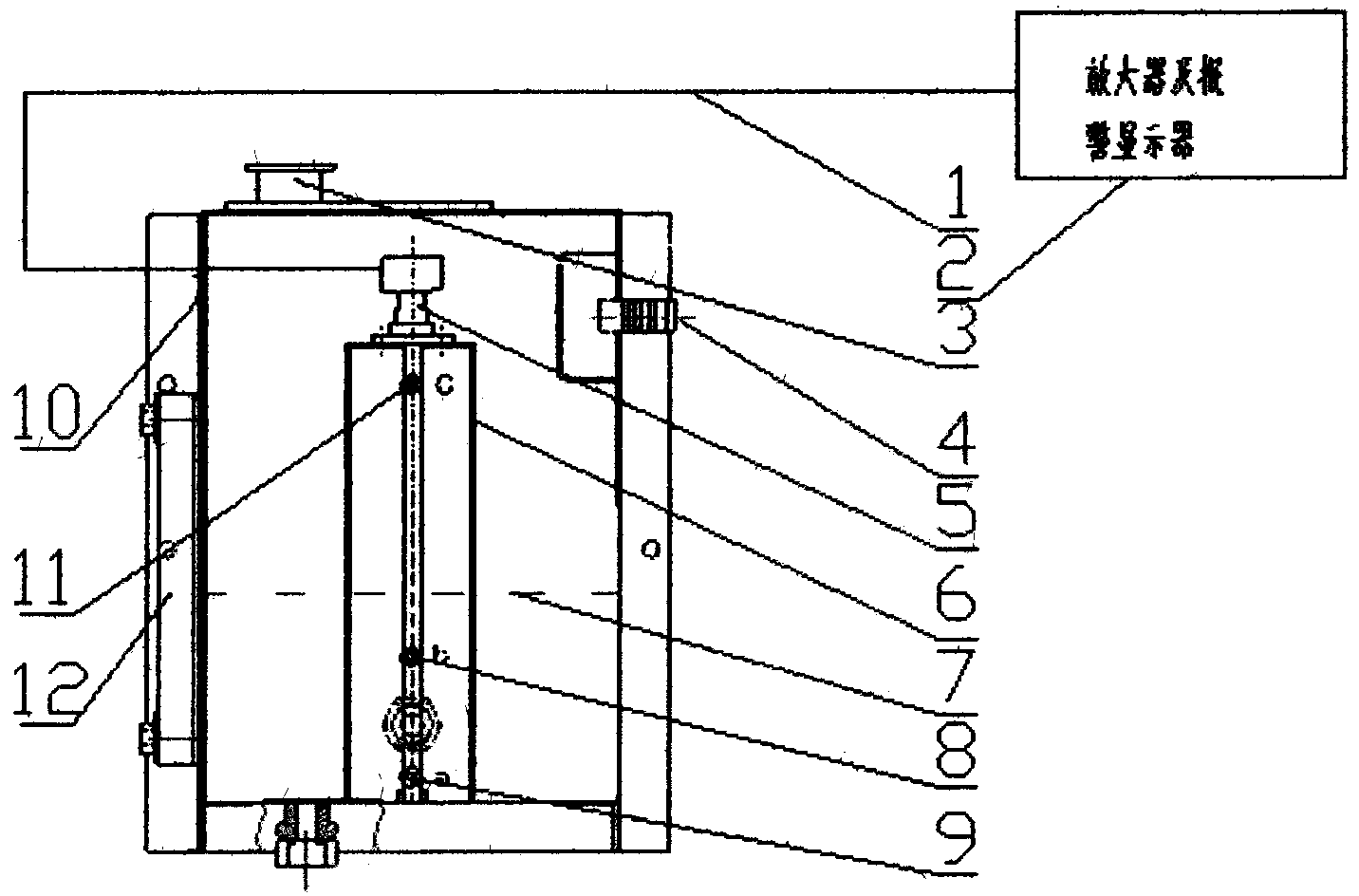

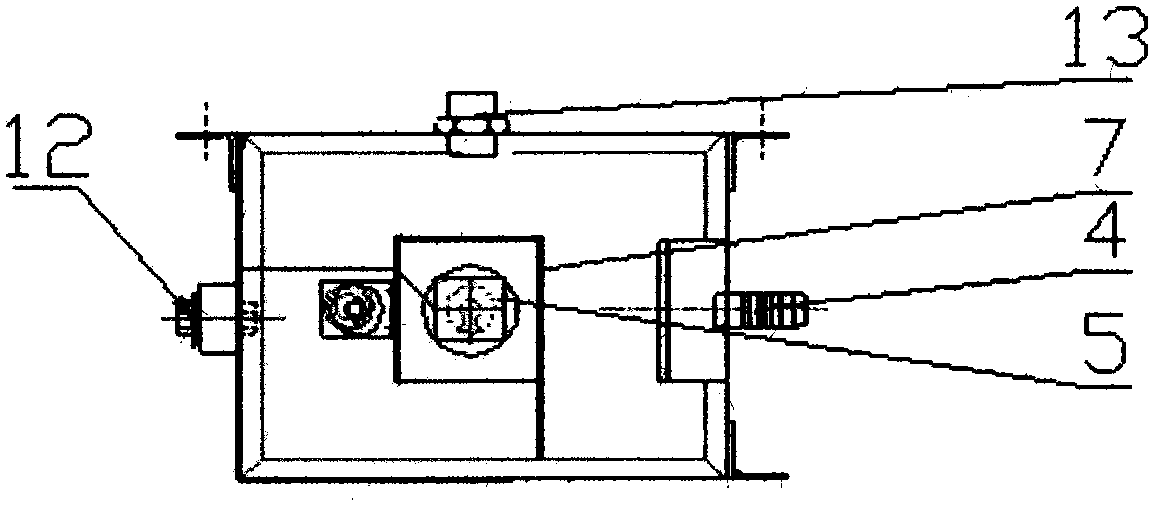

[0016] Examples, see attached figure 1 , 2 , hydraulic oil tank liquid level and density warning device, comprise oil tank body 10, described oil tank body has filling port 3, oil return port 4 and oil outlet 13, and support frame 6 is fixed in the described oil tank body, and described support frame A sensor assembly 5 is installed on it, and the induction output wiring harness 1 of the sensor assembly is connected with the signal amplification and alarm 2 located outside the fuel tank body.

[0017] The sensor assembly 5 is mainly composed of a-sensor 9 , b-sensor 8 and c-sensor 11 which are fixed on the support frame and arranged sequentially from bottom to top.

[0018] The c sensor exposes the hydraulic oil level line 7 in the oil tank.

[0019] A liquid level oil mark 12 is fixed on the side wall of the oil tank body.

[0020] The a sensor, the b sensor and the c sensor are differential pressure capacitance or piezoelectric ceramic sensors.

[0021] Working principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com