A blowing and paper pressing mechanism for a glazing machine

An air pressure and air pump technology, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of easy edge warping, paper blocking, lack of air blowing and pressing mechanism, etc., and achieves convenient disassembly and maintenance, structural Design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

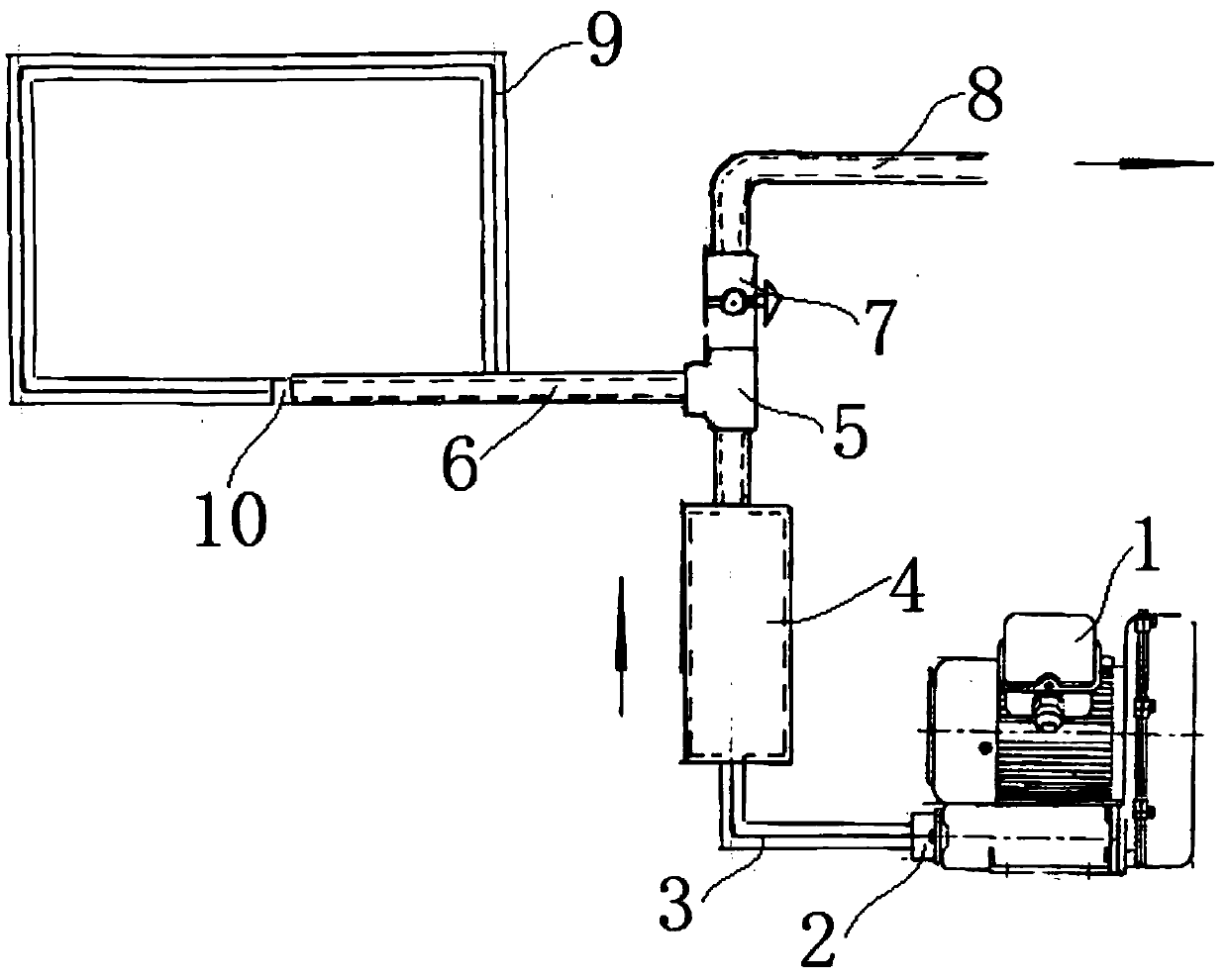

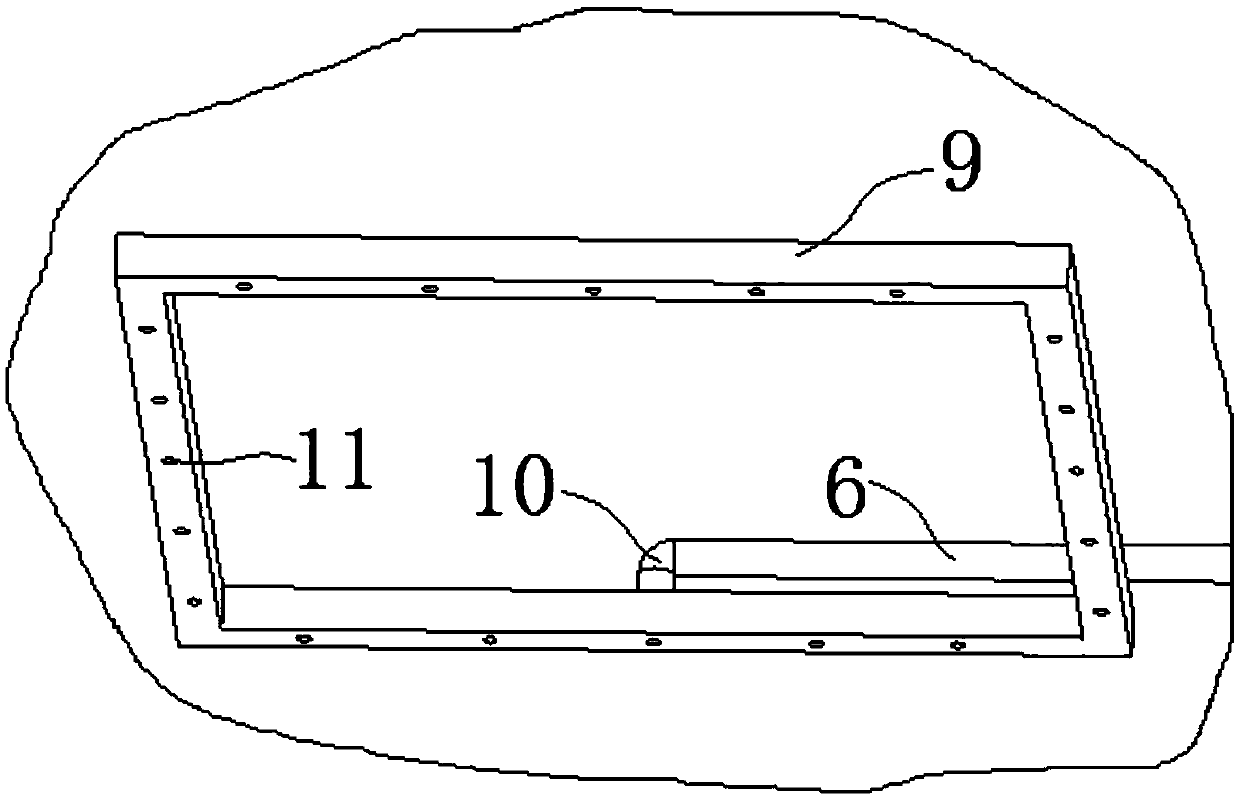

[0020] combine figure 1 and figure 2 , a kind of air blowing paper pressing mechanism used in the glazing machine of this embodiment can prevent the problem of paper blocking due to the easy warping of the paper in the process of conveying the paper, including the air pump 1, the coupling sleeve 2, the air pipe 3, Gas storage tank 4, tee pipe 5, air supply pipe 6, regulating valve 7, exhaust pipe 8, blowing pipe fitting 9 and right-angle elbow 10, wherein the main pipe of tee pipe 5 and the branch pipe of tee pipe 5 are perpendicular to each other and The air pump 1 communicates with one end of the air pipe 3 through the coupling sleeve 2, and the other end of the air pipe 3 communicates with the air inlet of the air storage tank 4; the air outlet of the air storage tank 4 is connected with the main pipe of the three-way pipe 5 One end is connected, and the other end of the main pipe of the three-way pipe 5 is connected with the exhaust pipe 8 through the regulating valve 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com