Working method of multifunctional marking press capable of switching automatic and manual paper feeding

A technology of manual paper feeding and working method, applied in printing presses, rotary printing presses, thin material handling, etc., can solve the problems of wasting resources, folding corners, paper jams, etc., achieving simple and convenient operation, high-efficiency indentation, saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

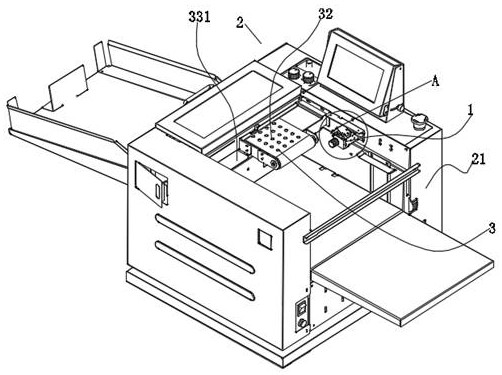

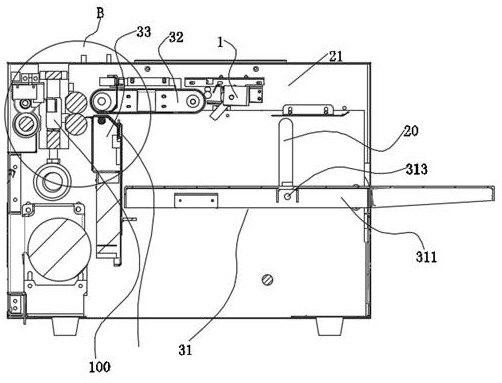

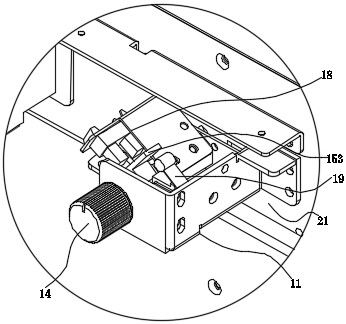

[0049] Such as Figure 1 to Figure 8 As shown, a multifunctional creasing machine includes a frame 21, on which a switching induction device 1 and a paper feeding unit 3 are arranged, and the paper feeding unit 3 includes a paper supporting device 31, a paper feeding device 32 And blower 33, paper supporting device 31 is positioned at frame 21 one ends; Blowing device 33 is close to frame 21 other ends; Paper feeding device 32 is positioned at paper supporting device 31 and blowing device 33 tops; Paper feeding device 32 and blowing device 33 A paper feeding channel 30 is formed between them; the switch sensing device 1 is arranged on the frame 21 at one end of the paper feeding device 32 , and the creasing unit 100 is provided at the other end of the frame 21 . The paper feeding unit 3 transports the paper to the creasing unit 100, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com