Automatic storage cabinet

An automatic storage and container technology, applied in the direction of storage devices, transportation and packaging, etc., can solve the problems of low equipment utilization, low work efficiency, high labor intensity, etc., to achieve accurate measurement of labor costs, save labor costs, save effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

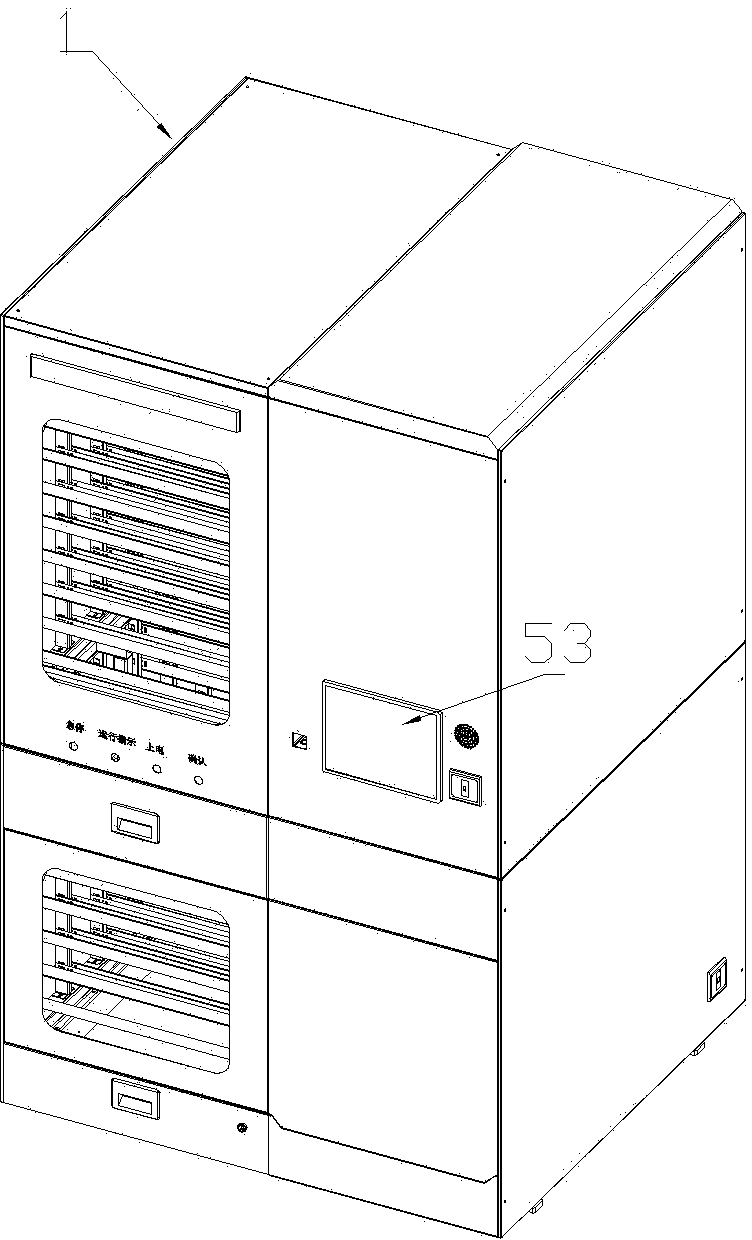

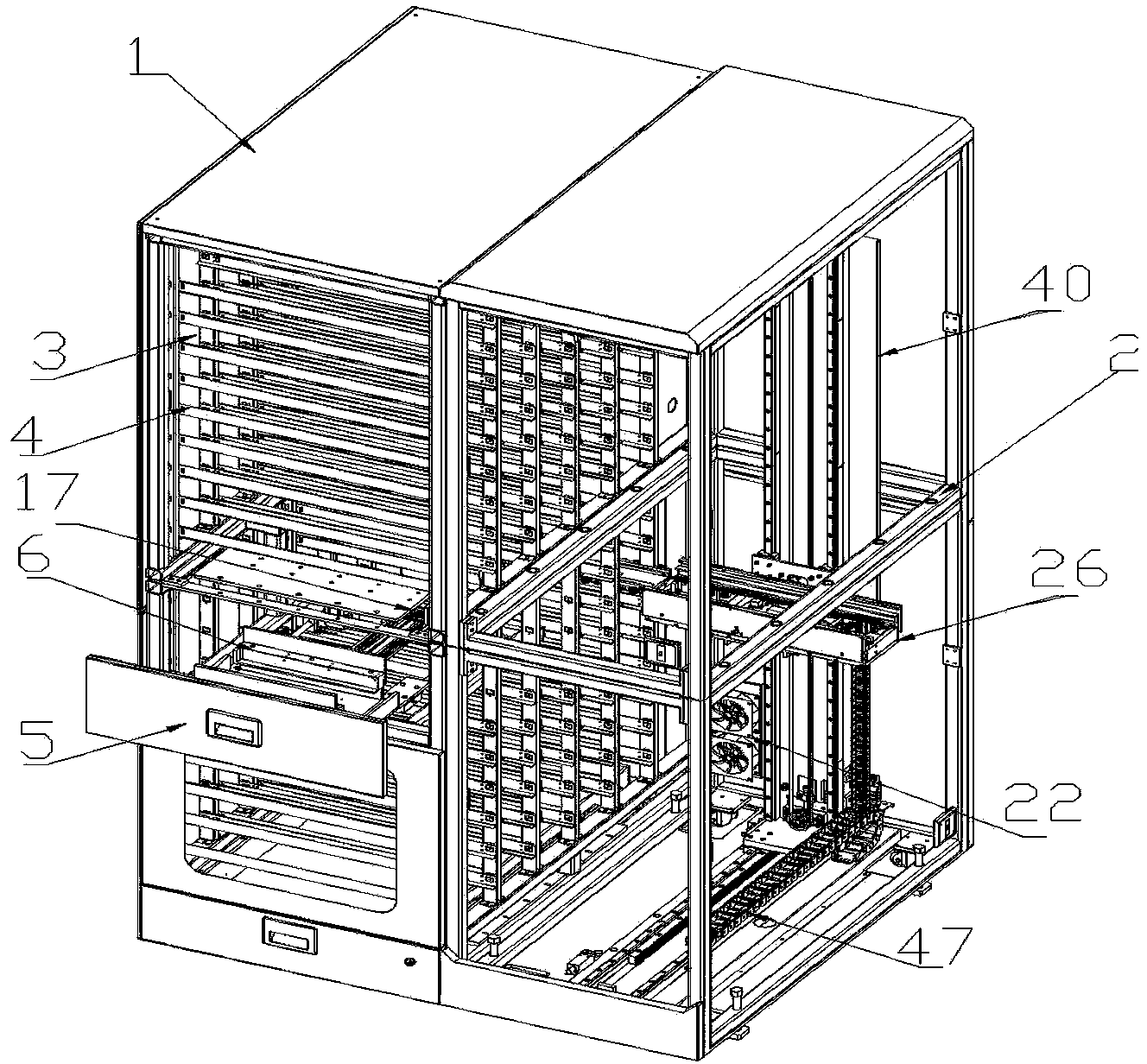

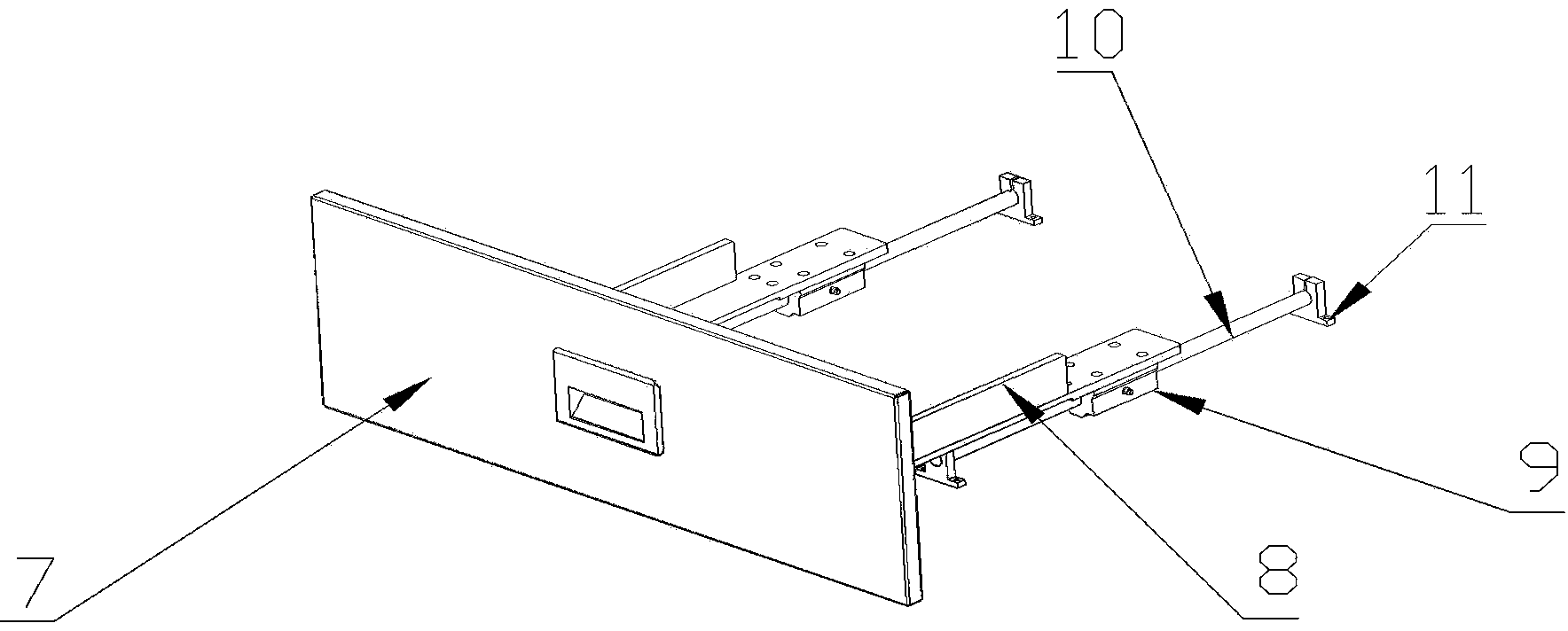

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the automatic storage container consists of two adjacent racks, a protective cover 5, an information collection unit 17, an X-axis manipulator 26, a Y-axis manipulator 47, a Z-axis manipulator 40, a defogging unit 22, a main control PLC, and a host computer composition;

[0032] Wherein: the frame I1 is the skeleton of the equipment, and other parts are directly or indirectly fixed thereon, the frame I1 is provided with vertical support rods 3, and every two vertical support rods 3 form an interval space, in the interval space There are hanging rods 4 inside, and every two hanging rods 4 form an installation plane, and the electric meter is stored on this plane, and the horizontal storage of electric meters is a feature of the invention;

[0033] The protective co...

Embodiment 2

[0054] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the automatic storage container can also be composed of three groups of racks, such as Figure 15 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com