A continuous mixing machine automatic feeding system

An automatic feeding and mixing machine technology, applied in the field of rubber machinery, can solve the problems of inability to achieve continuous weighing and feeding, inability to control the feeding speed of auxiliary materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

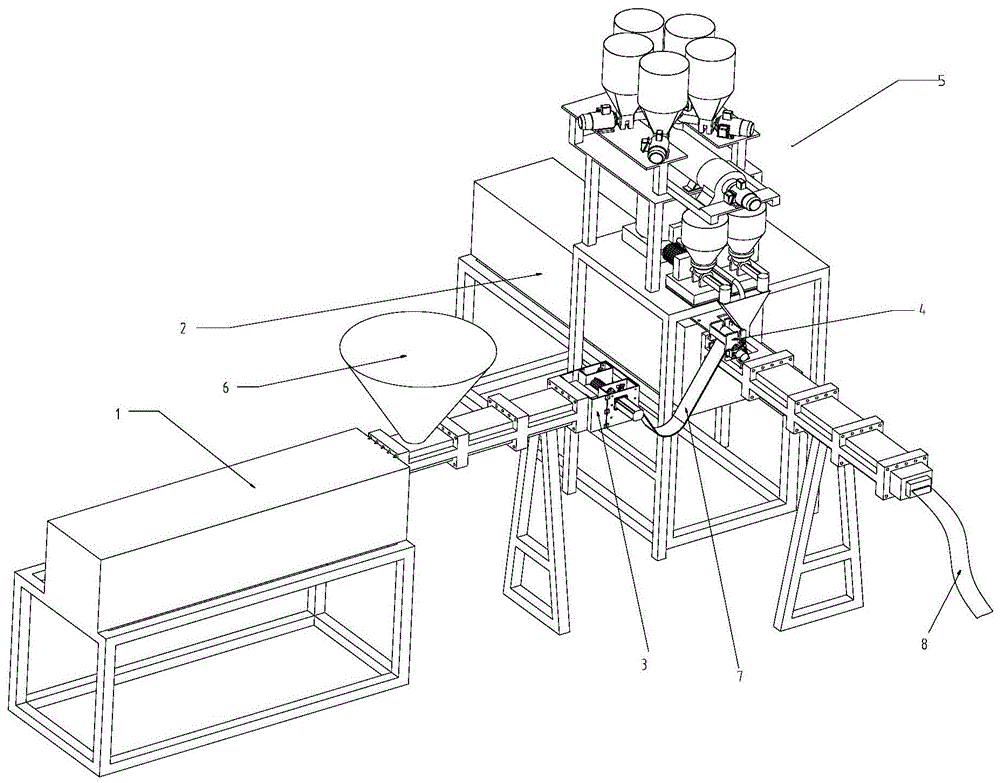

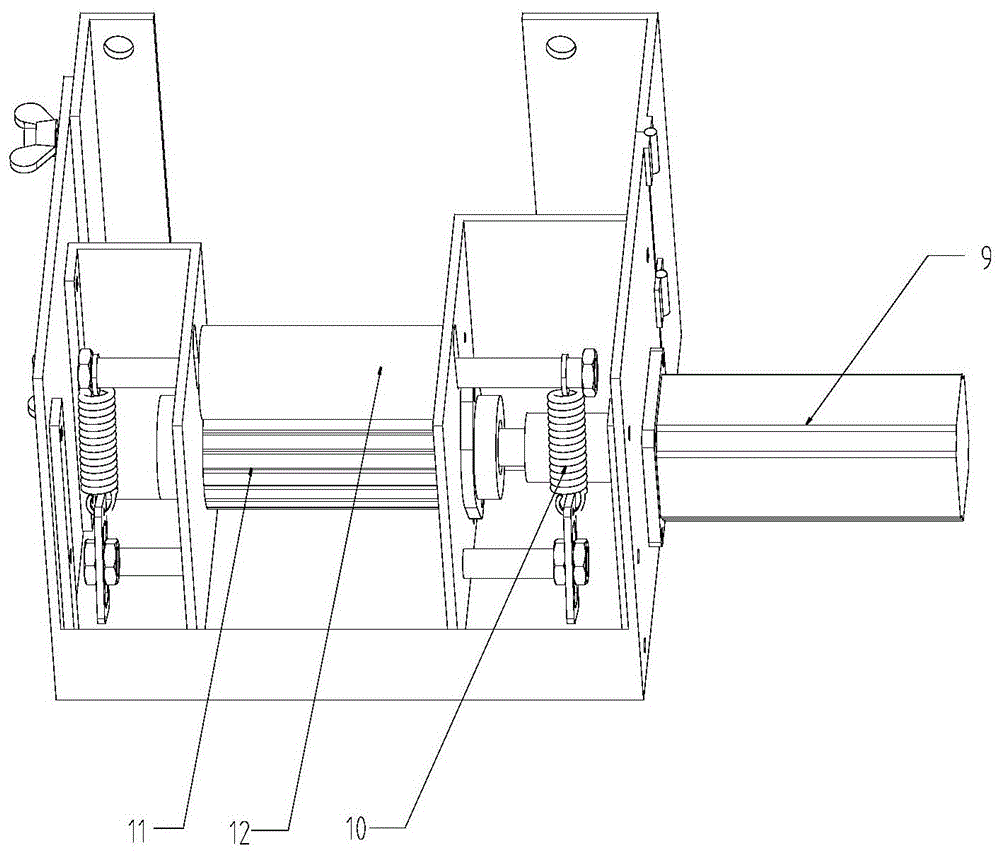

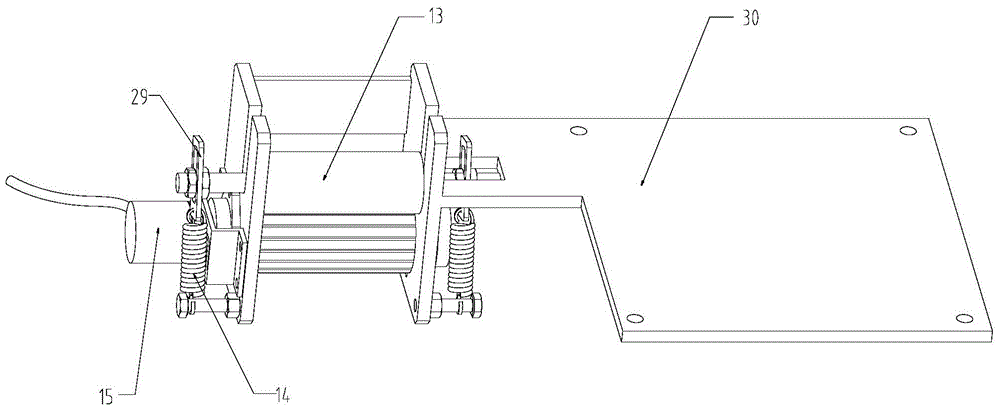

[0025] Such as figure 1 As shown, the present invention includes a continuous plastic mixer 1, a rubber pulling mechanism 3, a continuous mixer 2, a rubber strip measuring mechanism 4, a continuous feeding mechanism 5 and an oil metering scale 26. Such as figure 2 As shown, the glue pulling mechanism includes a first motor 9 , a first spring 10 , a driving roller 11 and a driven roller 12 . Such as image 3 As shown, the rubber strip measuring mechanism includes an automatic roller 13, a second spring 14 and an encoder 15. The automatic roller is composed of upper and lower rollers. The second spring makes the two rollers compress each other, and the rubber strip passes through the two rollers. Such as Figure 4 As shown, the feeder includes a barrel 16, a feeding screw 17 and a second motor 18; the distribution mechanism includes a third motor 21 and a distribution port 22; the agitator includes a mixing drum 19, a stirring screw 20 and a fourth motor 27; weight loss The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com