Abrasive belt grinding and polishing machine

A polishing machine, abrasive belt technology, applied in abrasive belt grinders, grinding/polishing equipment, grinding racks, etc. space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

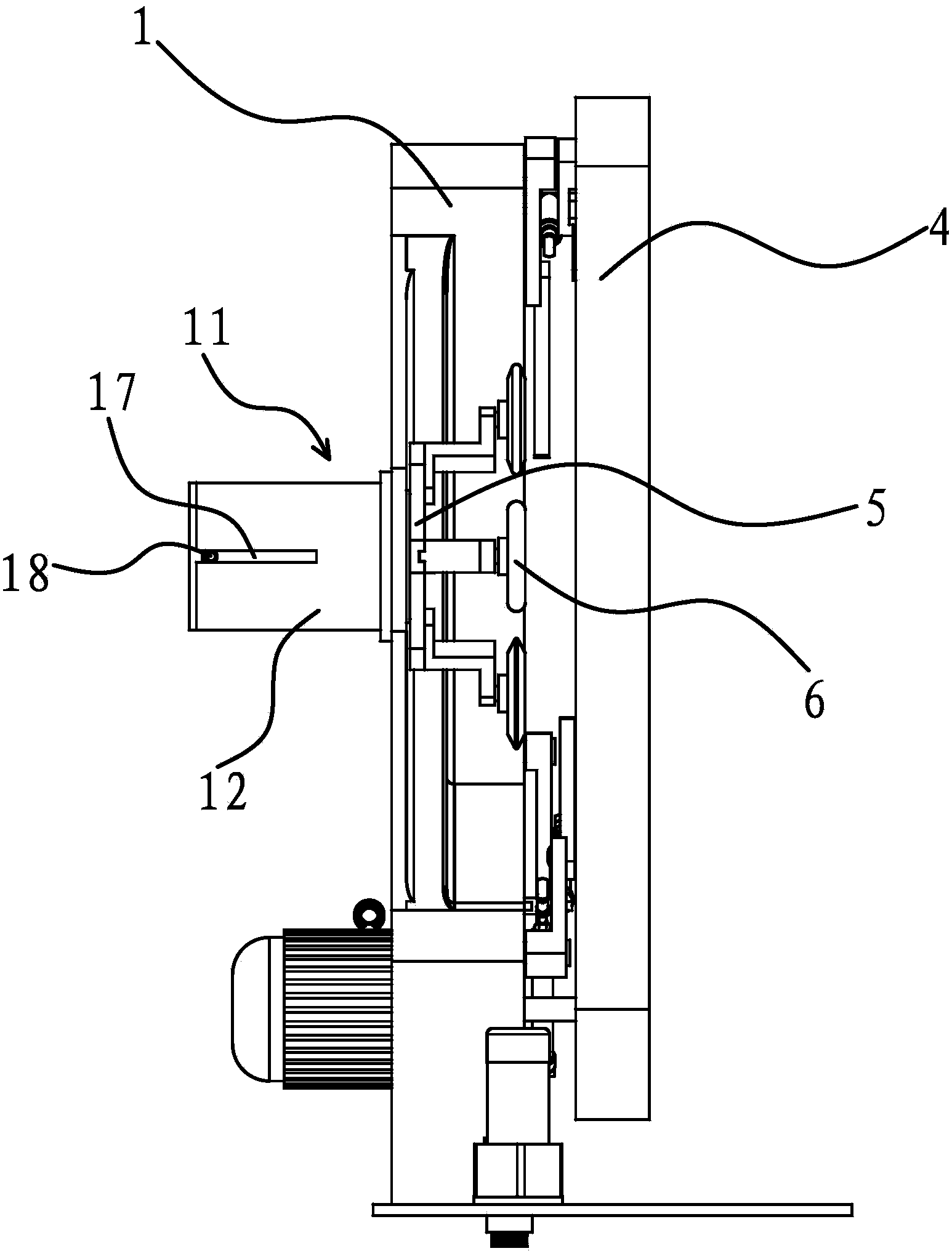

[0044] Such as figure 1 , image 3 and Figure 5 As shown, an abrasive belt grinding and polishing machine includes a frame 1 and a driving wheel 2, a driven wheel 3 and an abrasive belt 4 arranged on the frame 1. A turntable 5 is arranged in the middle of one side of the frame 1, and the periphery of the turntable 5 is A number of grinding wheels 6 are connected with the center of rotation of the rotating disk 5 as the center of the circle, and the curvatures of the wheel edge curved surfaces of each grinding wheel 6 are not the same. The frame 1 is provided with a positioning column 24 near the inner side of the abrasive belt 4 on the upper part of the side of the rotating disk 5. The driven wheel 3 is fixed on the positioning column 24, and a connecting rod 7 is sleeved on the positioning column 24. The connecting rod 7 is Axially fixed between the driven wheel 3 and the side of the frame 1, the end of the connecting rod 7 is fixed with a grinding wheel 6, and the upper p...

Embodiment 2

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the other side of the frame 1 provided with the turntable 5 is fixed with a casing, the driving mechanism includes a rotating motor fixed at the end of the casing, and the frame 1 There is a through hole on the side corresponding to the turntable 5, and the through hole is connected with a positioning sleeve with a cavity inside through a thread, the positioning sleeve is located in the casing and the output shaft of the rotating motor is connected to one end of the positioning sleeve, A rotating motor 14 is arranged in the positioning sleeve, and the output shaft of the rotating motor 14 stretches out from the other end of the positioning sleeve and links to each other with the rotating disk 5 .

[0059] Control the forward rotation of the output shaft of the rotary motor. Since the output shaft of the rotary motor is connected with the positioning slee...

Embodiment 3

[0061] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the other side of the frame 1 provided with the turntable 5 is fixed with a casing, the driving mechanism includes a rotating motor fixed at the end of the casing, and the frame 1 There is a through hole on the side corresponding to the turntable 5, and the through hole is connected with a positioning sleeve with a cavity inside through a screw thread. Inside and at an end of the locating sleeve, an internal gear ring is fixed, a number of transmission gears 2 are also arranged between the transmission gear 1 and the internal gear ring, and a rotating motor 14 is arranged in the positioning sleeve, and the output shaft of the rotating motor 14 is self-positioning. The other end of sleeve protrudes and links to each other with rotating disk 5.

[0062] When the output shaft of the rotary motor rotates forward, the transmission gear 1 at the end of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com