Osteochondral three-dimensional stent with regular interpenetrating network structure and preparation method thereof

A technology of interpenetrating network structure and three-dimensional scaffold is applied in the field of osteochondral three-dimensional scaffold and its preparation, which can solve the problem that the mechanical strength of the scaffold is not taken into account, and achieve the effect of a large control range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

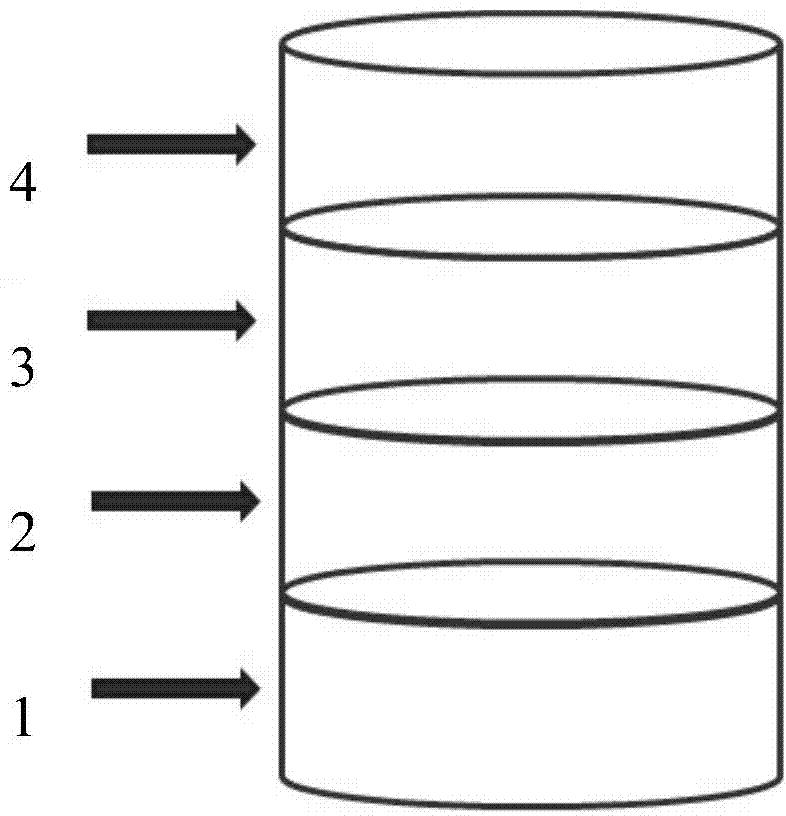

[0035] Osteochondral three-dimensional scaffold with regular interpenetrating network structure in this embodiment: a regular interpenetrating network structure is formed by biomedical polymer material system and in-situ generated hydrogel material system, including calcification layer, radiation layer, transition layer and In the shallow surface layer, each layer is connected to each other, and the internal pores are square. The thickness of the calcification layer is 100 μm, the thickness of the radiation layer is 1000 μm, the thickness of the transition layer is 500 μm, and the thickness of the superficial layer is 100 μm. The pore size of the calcified layer and the radioactive layer is 50 μm, and that of the transition layer and superficial layer is 20 μm.

[0036] Among them, the biomedical polymer material system is composed of polyurethane and hydroxyapatite. The content of polyurethane in the biomedical polymer material system of the calcification layer is 70wt%, and ...

Embodiment 2

[0044] Osteochondral three-dimensional scaffold with regular interpenetrating network structure in this embodiment: a regular interpenetrating network structure is formed by biomedical polymer material system and in-situ generated hydrogel material system, including calcification layer, radiation layer, transition layer and The superficial layer, each layer is connected with each other, including the calcified layer, the radiation layer, the transition layer and the shallow surface layer, the layers are connected with each other, and the internal holes are square. The thickness of the calcified layer is 1500 μm, the thickness of the radioactive layer is 3000 μm, the thickness of the transition layer is 2000 μm, and the thickness of the superficial layer is 3000 μm. The pore diameter of the calcification layer and the radiation layer is 500 μm, and the transition layer and superficial layer and the pore diameter are set as 800 μm.

[0045] Among them, the biomedical polymer mat...

Embodiment 3

[0054] Osteochondral three-dimensional scaffold with regular interpenetrating network structure in this embodiment: a regular interpenetrating network structure is formed by biomedical polymer material system and in-situ generated hydrogel material system, including calcification layer, radiation layer, transition layer and In the shallow surface layer, each layer is connected to each other, and the internal pores are square. The thickness of the calcified layer is 500 μm, the thickness of the radioactive layer is 2000 μm, the thickness of the transition layer is 1500 μm, and the thickness of the superficial layer is 2500 μm. The pore structure inside the scaffold is set to be square; the pore diameter of the calcification layer and the radiation layer is set to 450 μm, and the transition layer and superficial layer and the pore diameter are set to 200 μm.

[0055] Among them, the biomedical polymer material system is composed of polycaprolactone and tricalcium phosphate; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com