Pilot plant test sterilization system

A sterilization device and heat exchanger technology, applied in food science, food preservation, food heat treatment, etc., can solve the problems of large production capacity, inconvenient maintenance and repair, and many raw materials of the sterilization system, achieving easy operation and maintenance, and small footprint. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

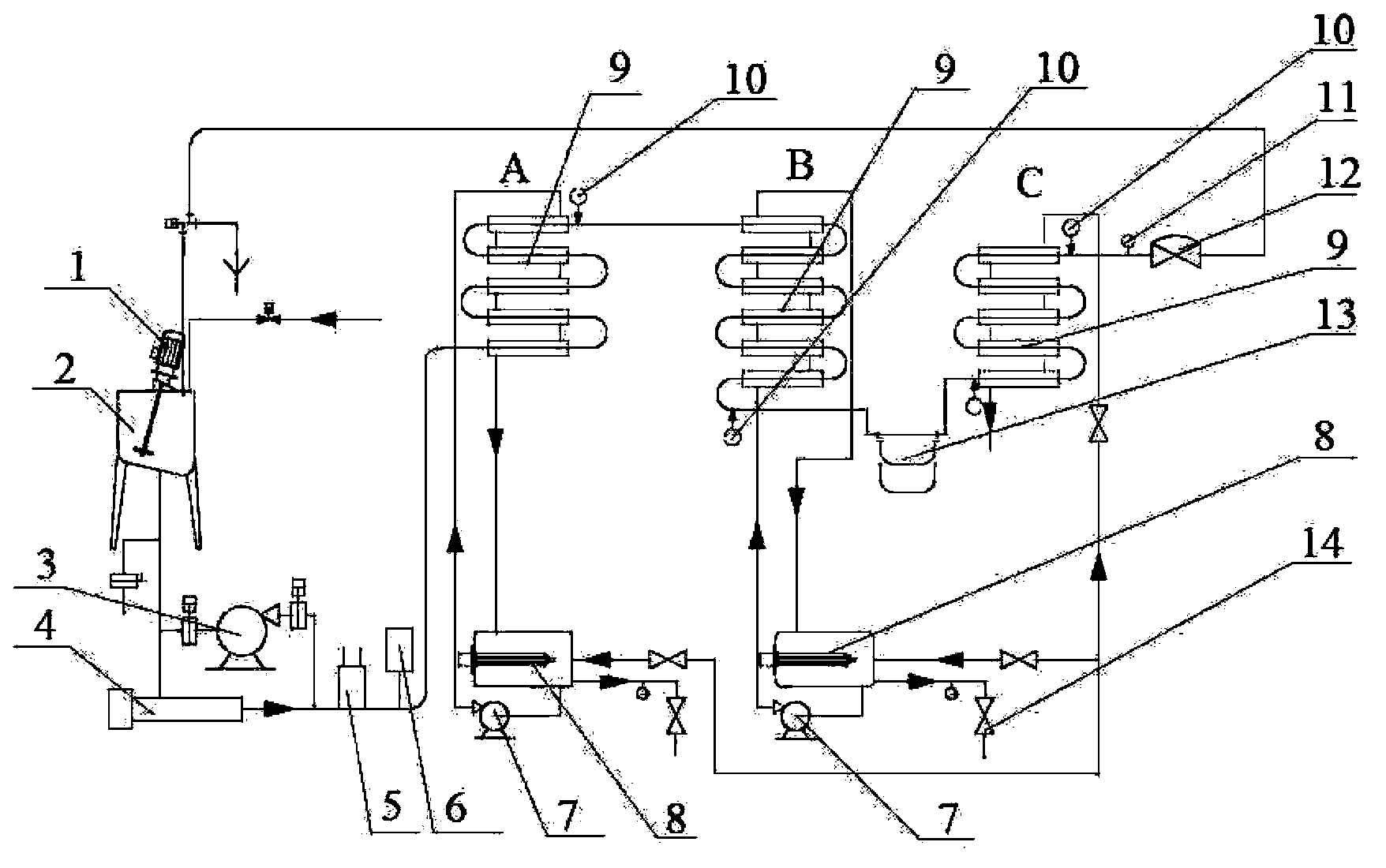

[0024] A pilot sterilization system, such as figure 1 As shown, the system includes a balance cylinder 2, a material pump 4, a preheating device A, a sterilizing device B, a temperature maintaining pipe 13 and a cooling device C connected sequentially through pipelines, and the pipeline is provided with a safety valve 5, a pressure sensor 11, Temperature probe 10 and back pressure valve 12. Both the preheating device A and the sterilizing device B include a heat exchanger and heat supply equipment connected to the heat exchanger. The heat exchanger is a tubular heat exchanger 9, the heating equipment is a heating boiler 8, and a heater is arranged in the heating boiler 8, and the heating boiler 8 and the tubular heat exchanger 9 are connected by a pipeline, and the heating boiler 8 The hot water inside flows through the outer tube of the sleeve-and-tube heat exchanger 9, and the material in the inner tube of the sleeve-and-tube heat exchanger 9 is heated by the hot water. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com