Pruning tool

A technology of trimming tools and front shells, applied in the field of trimming tools, can solve the problems of difficult control during rotation, uneven force on front and rear hands, inconvenient holding of front handles, etc., so as to avoid rapid fatigue, uniform force on front and rear hands, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be described in detail below with a preferred embodiment in conjunction with the accompanying drawings.

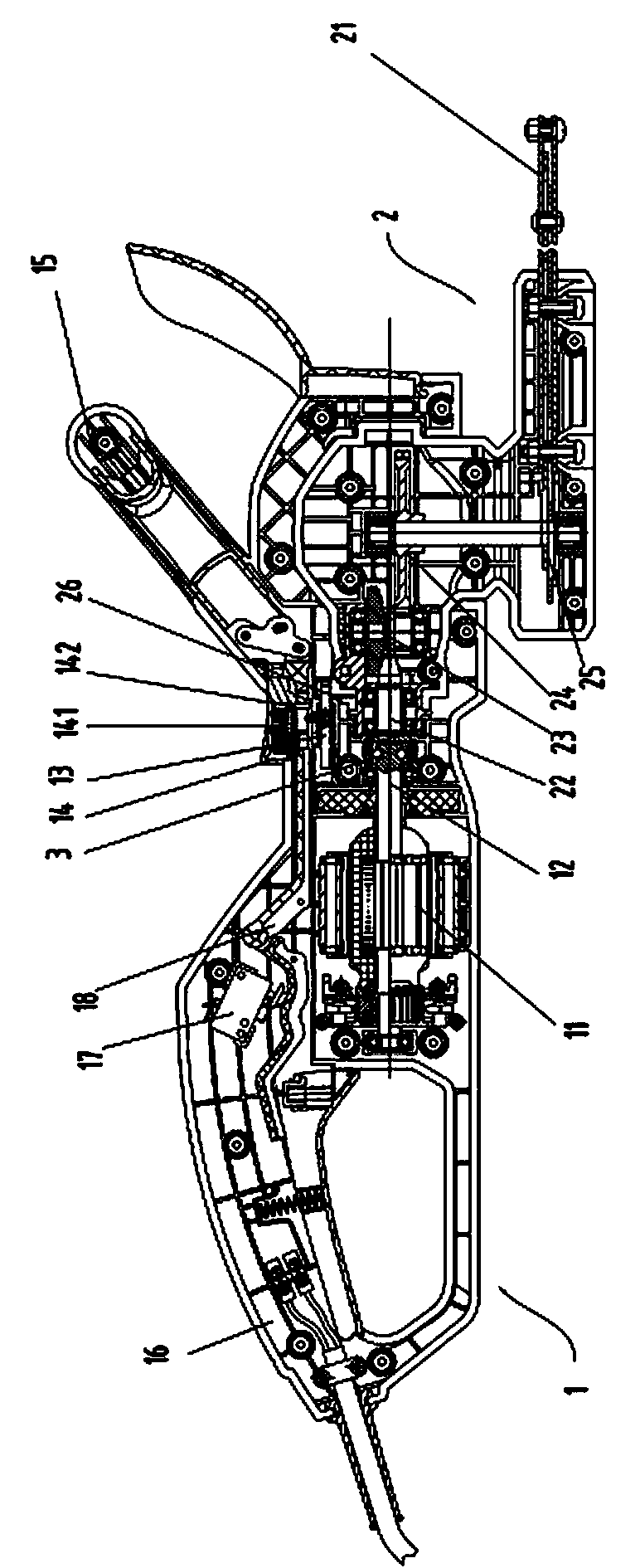

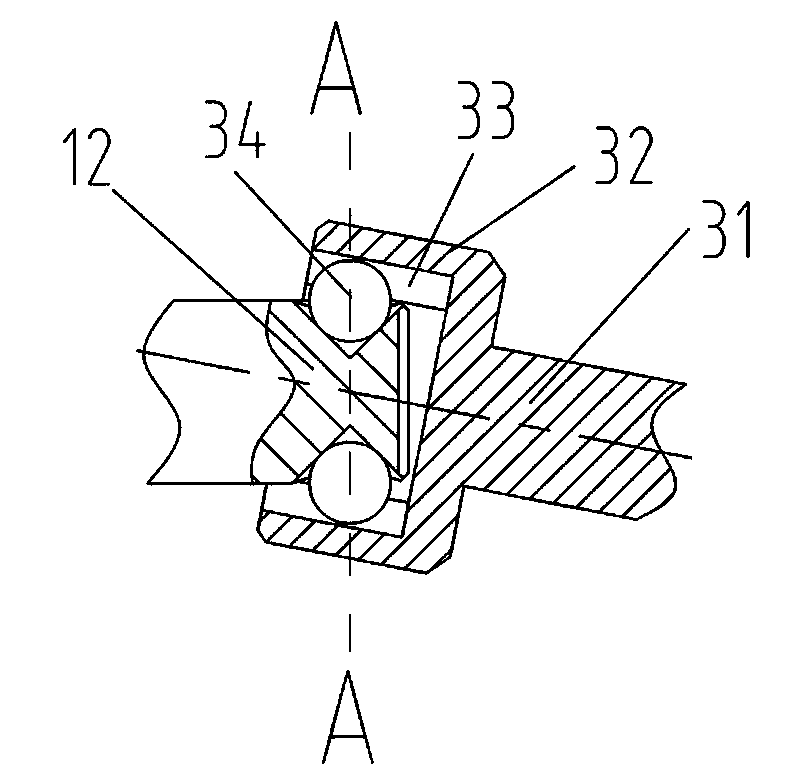

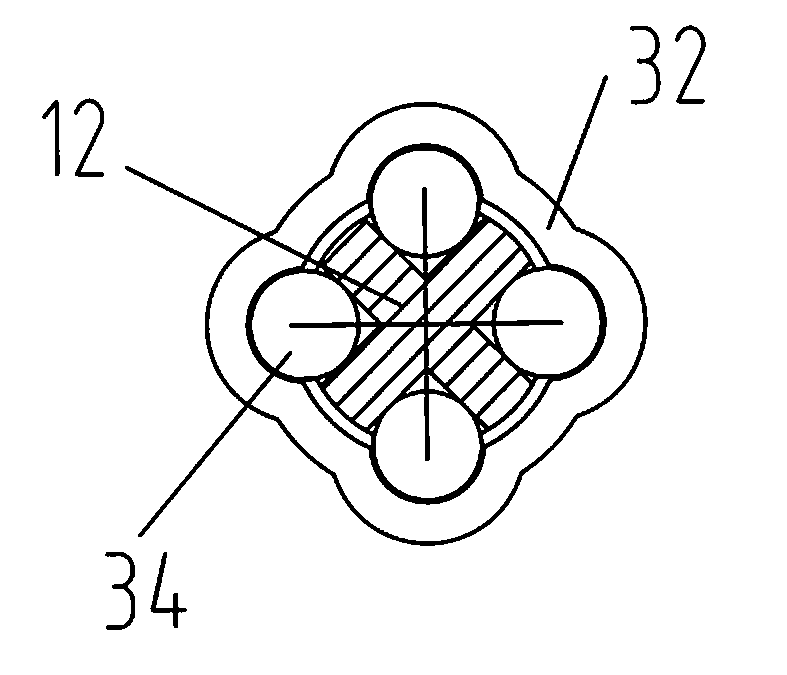

[0016] Refer to attached figure 1 Shown, a kind of pruning tool, it comprises front shell 2, rear shell 1, the universal joint 3 that is arranged between front shell 2 and rear shell 1, the motor 11 that is fixedly arranged in rear shell 1, is arranged on front shell 2, the output shaft 12 of the motor is transmitted with the universal joint 3, the front shell 2 can rotate relative to the rear shell 1 under the drive of the universal joint 3, and the front shell 2 is also set There is a transmission mechanism for transmitting the driving force received by the universal joint 3 to the blade 21 .

[0017] It also includes a locking mechanism for locking the front case 2, the locking mechanism includes a locking piece 13 and a button 14 for operating the locking piece. One end of the button 14 is connected with a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com