Rotary evaporator

An evaporator and rotary technology, applied in the field of rotary evaporators, can solve problems such as cracking, difficulty in replacing and reinstalling evaporating vessels, fragile evaporating vessels, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

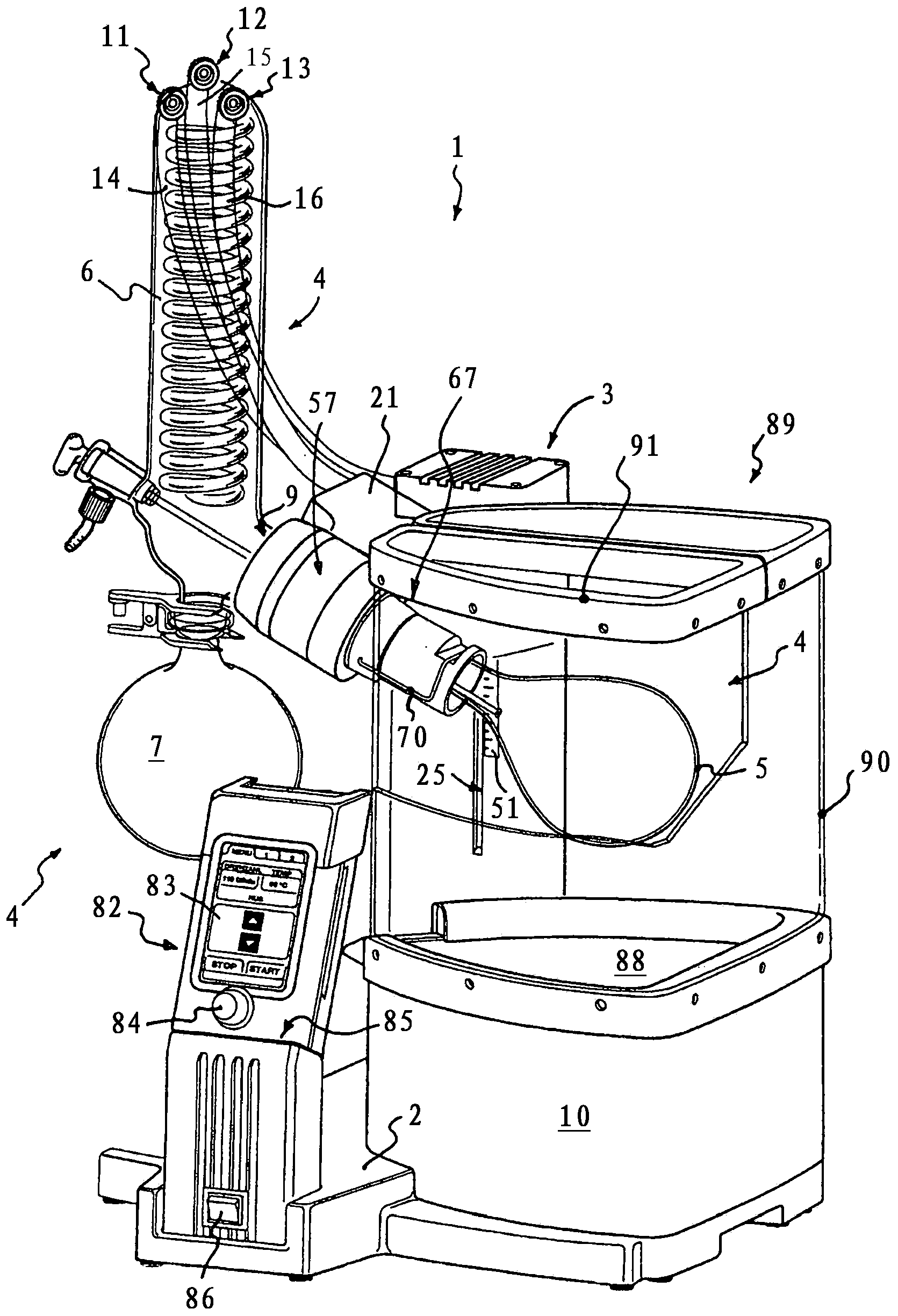

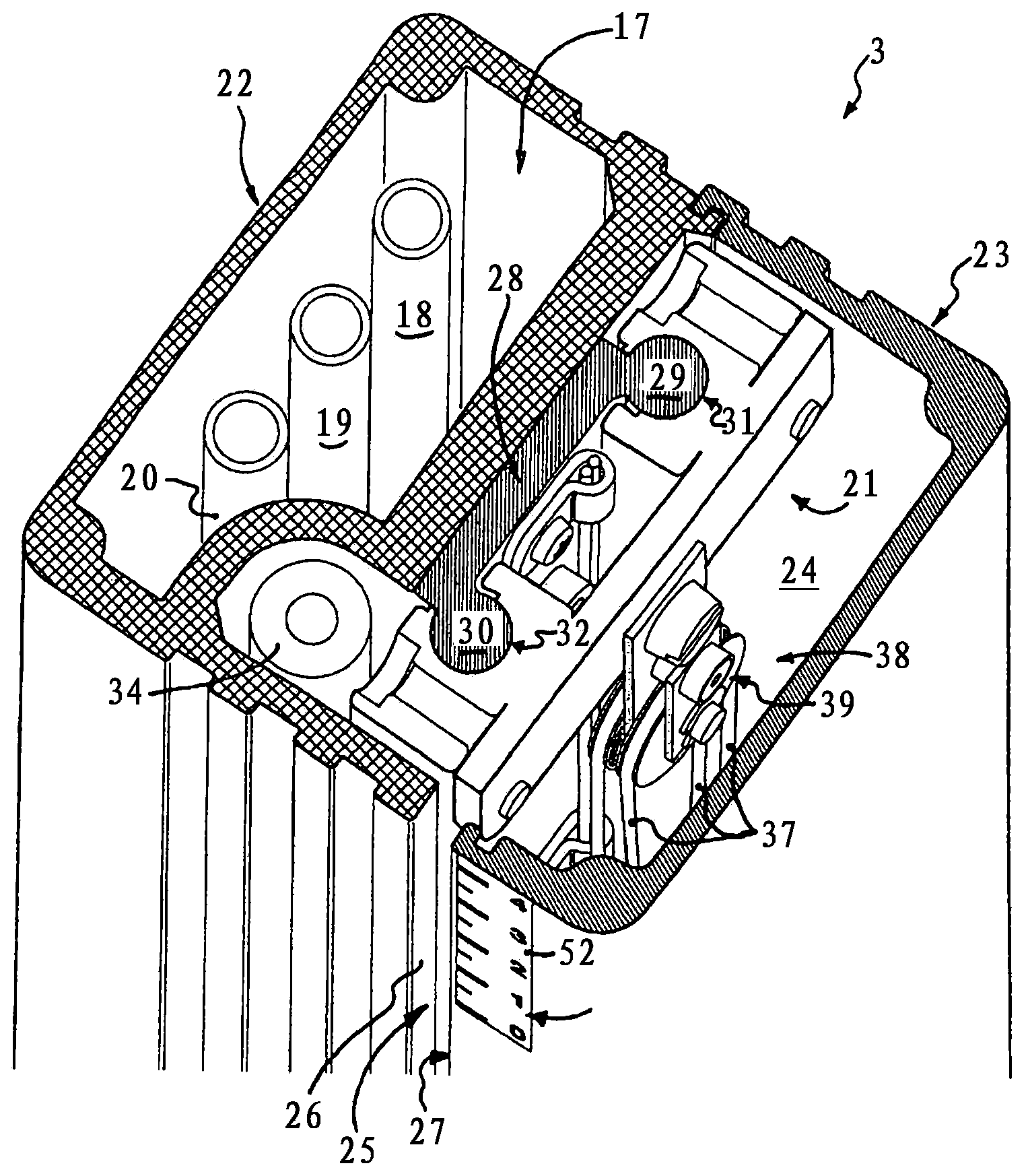

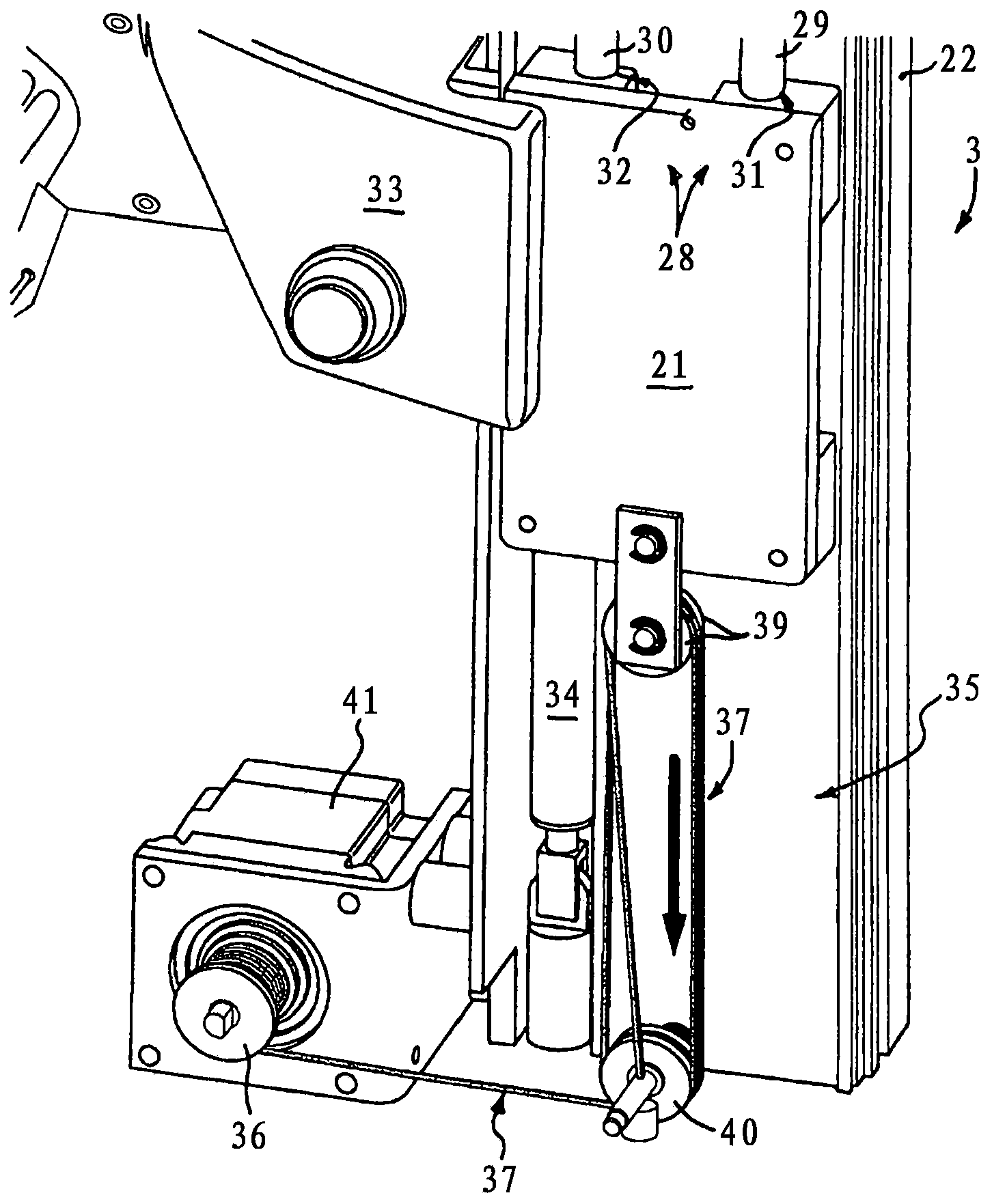

[0028] exist figure 1 shows a rotary evaporator 1 in a perspective view. The rotary evaporator 1 has an instrument base 2 that supports the structure of the rotary evaporator. A guide tower 3 with a vertically directed longitudinal axis protrudes from the instrument base 2 . The rotary evaporator 1 has a glass unit 4 with an evaporator vessel 5 designed here as an evaporator flask, a cooler 6 and a collection vessel 7 detachably connected to the cooler 6 . Here the evaporator vessel 5 is held as a vapor guiding device and in the Image 6 , 7 In the case of the glass hollow shaft 8 further shown in and 9 , the shaft end of the glass hollow shaft facing away from the evaporator vessel 5 leads into the connection pipe 9 of the cooler 6 .

[0029] The rotary evaporator 1 has a tempering vessel 10 , here designed as a heat bath, into which the evaporator vessel 5 is partially immersed. In order to be able to position subregions of the evaporator vessel 5 in the tempering vesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com