A mechanical x-ray source

A mechanical, X-ray technology, applied in the basic research field of interface multi-physics, can solve the problems of reduced adhesive force of tapes, difficult to obtain a stable X-ray source, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

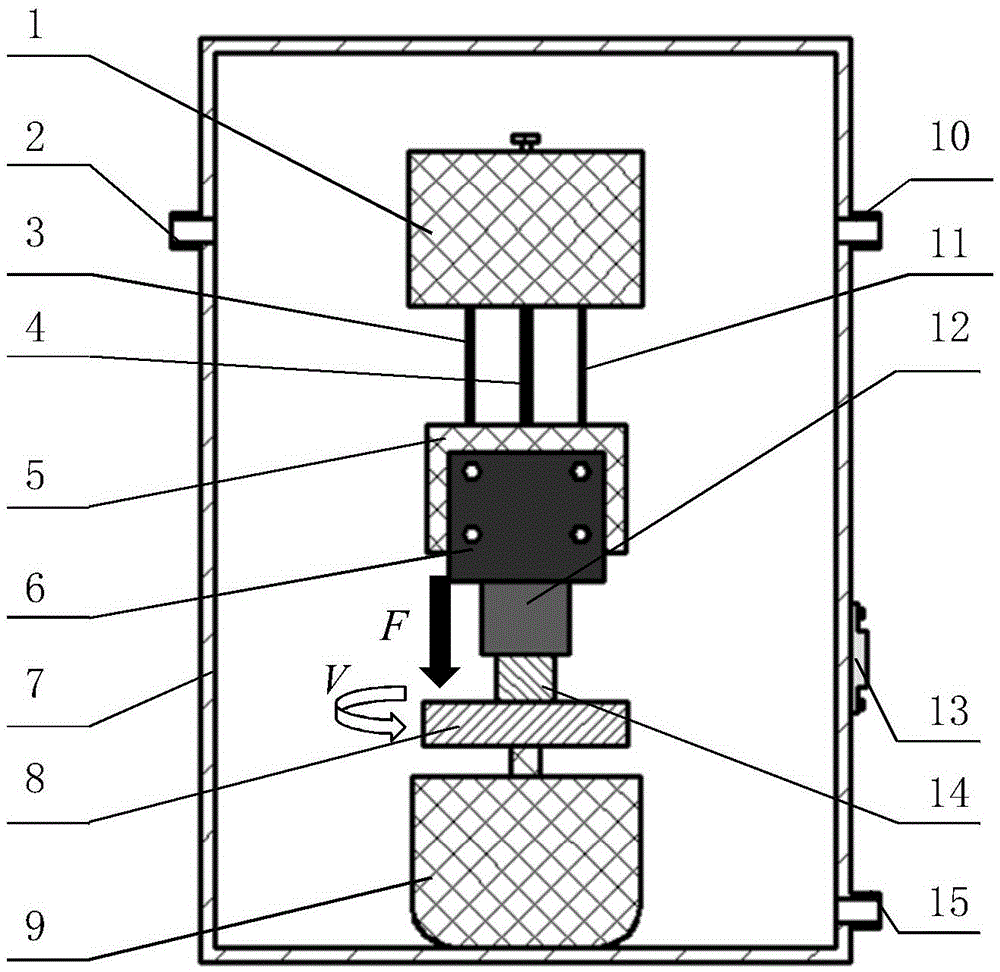

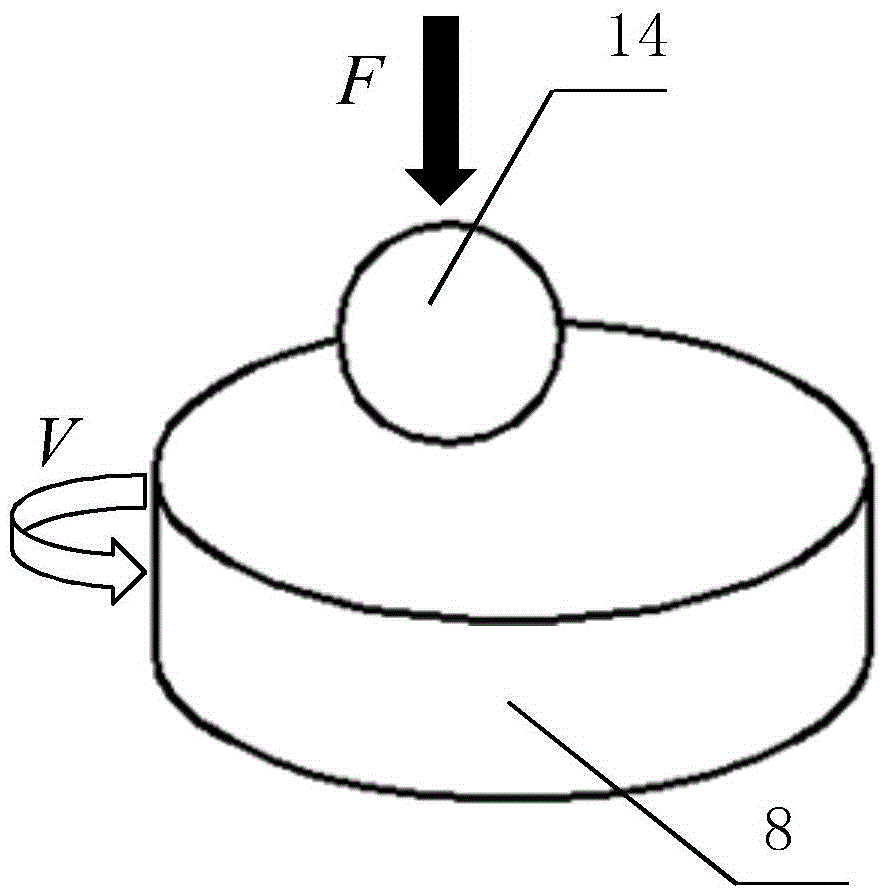

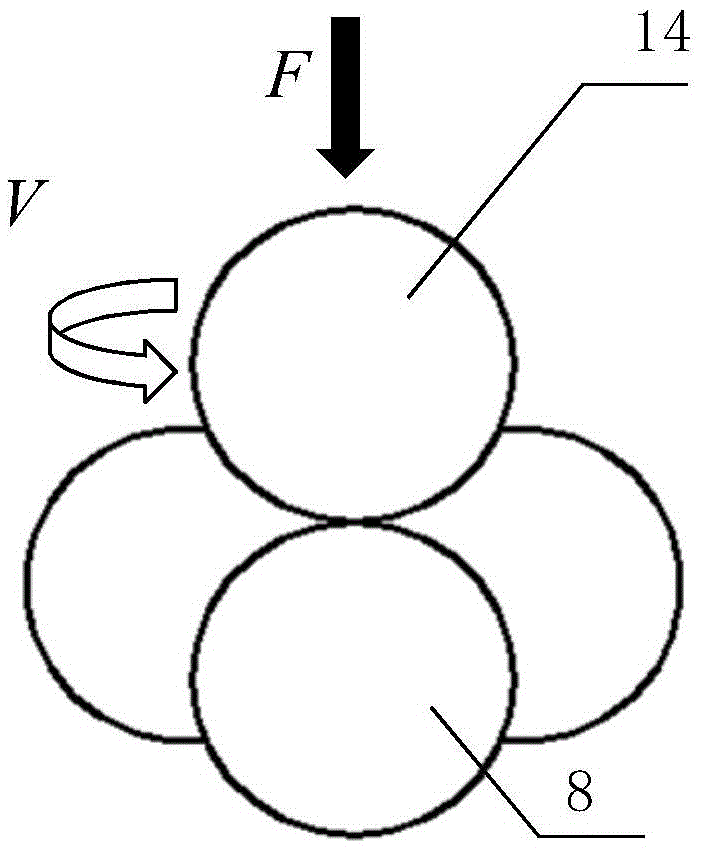

[0016] The mechanical X-ray source proposed by the present invention has a structure such as figure 1 As shown, it includes a sealing cover 7 , a force applying motor 1 , a moving platform 5 , a force sensor 6 , an upper friction pair 14 , a lower friction pair 8 and a rotating motor 9 . The force applying motor 1, the mobile platform 5, the force sensor 6, the upper friction pair 14, the lower friction pair 8 and the rotating motor 9 are installed in the sealing cover 7 sequentially from top to bottom. The force applying motor 1 moves the mobile platform 5 up and down through the lead screw 4 . The force sensor 6 is relatively fixed to the mobile platform 5 , and the detection end of the force sensor 6 is linked with the upper friction pair 14 through the connecting piece 12 . The rotary motor 9 is installed at the bottom of the sealing cover 7, and the output shaft of the rotary motor 9 drives the friction pair 8 to rotate. The upper friction pair 14 is in close contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com