An Adaptive Method for Emergency Shedding of Induction Motor Load Based on Slip Response

A technology of induction motor and slip rate, which is applied in the direction of motor control, electrical components, AC network voltage adjustment, etc., can solve the adverse effects of power system stability and economy, does not fully consider the mutual coupling characteristics of frequency and voltage, and does not consider the voltage Time and space distribution and other issues, to achieve the optimal steady state recovery index, ensure voltage stability and frequency stability, and fast system transient recovery process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

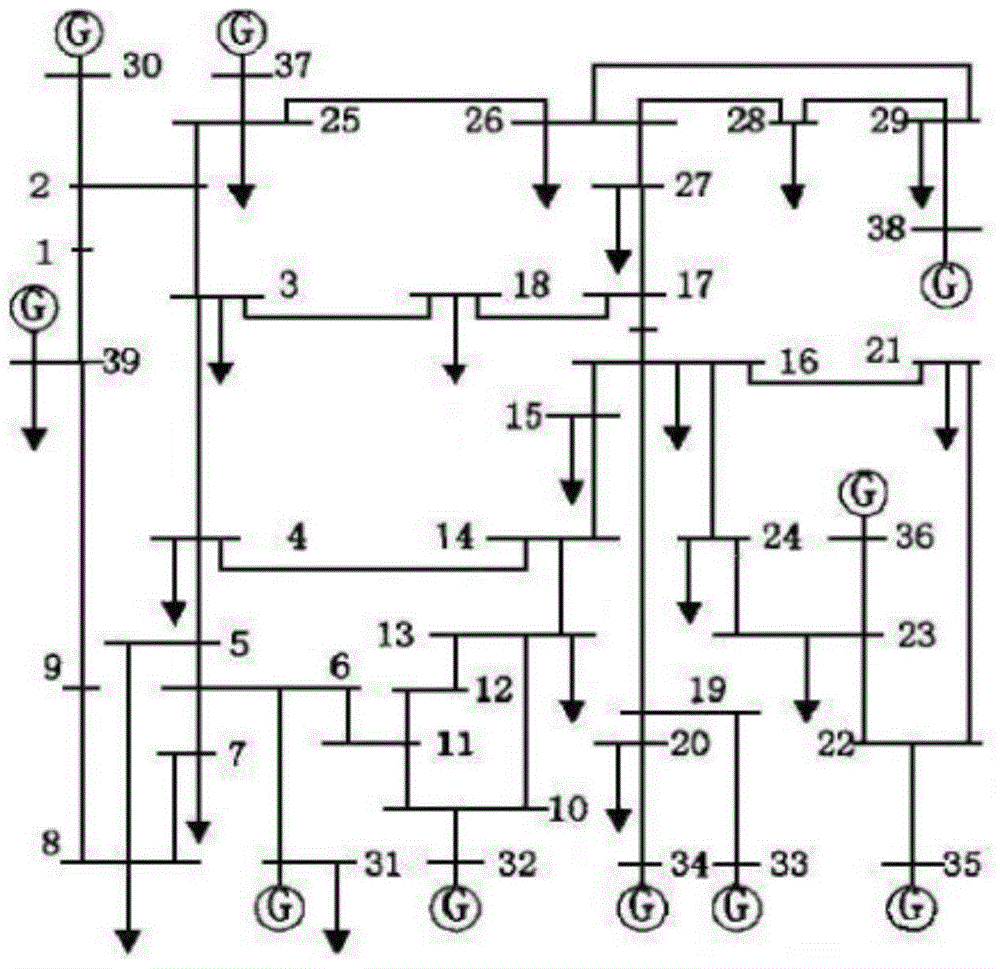

[0033] Such as figure 1 As shown, the IEEE39 node system, considering the generator voltage regulator and governor, the load adopts a 70% induction motor and 30% constant impedance parallel model, the motor considers the electromagnetic transient process of the rotor, and the simulation is carried out on PSASP with a step size of 0.01 seconds , with a duration of 10 seconds.

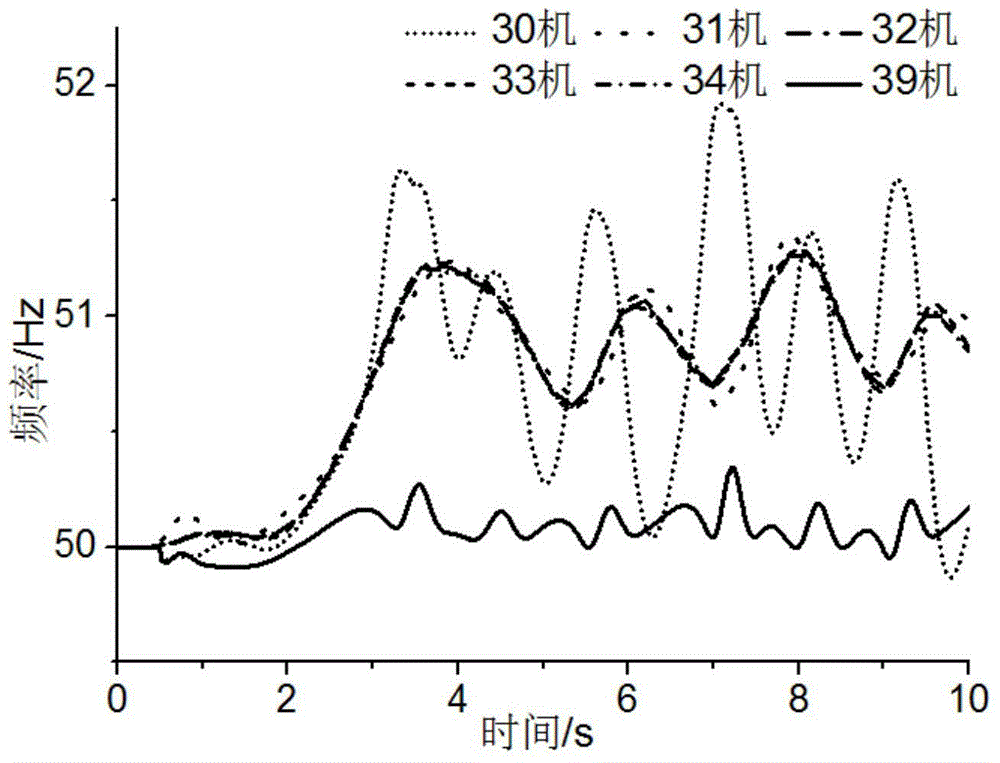

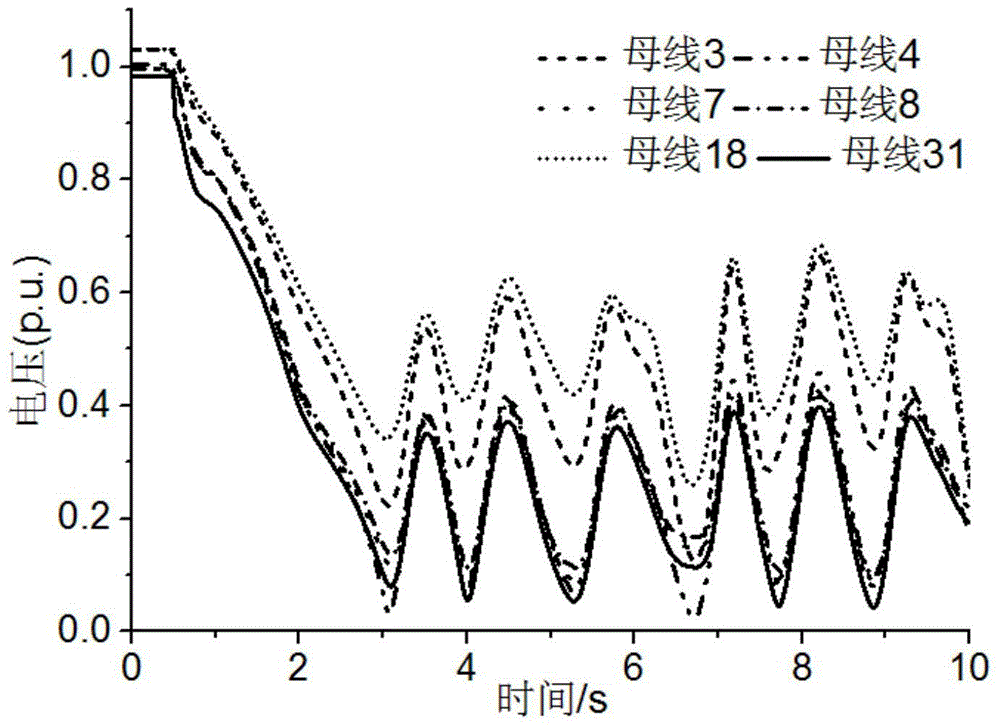

[0034] The failure mode is 0.5 seconds, unit 31 tripped, and the two adjacent lines 6-11 and 4-14 were disconnected at the same time. The original active output of the system was 6141.208MW, and the active power of the load was 6097.5MW. After the failure, the system lost active power 520MW. After the failure, the system will experience power angle instability, frequency instability and voltage instability, and the system will oscillate violently, and the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com