Four-connecting-rod mass-center-adjustable patrol robot mechanism

An inspection robot and four-bar linkage technology, applied in the field of mobile robots, can solve the problems of difficult to apply ultra-high voltage transmission line inspection operations, complicated process of crossing obstacles, and unsuitable control, etc. The effect of strong disability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

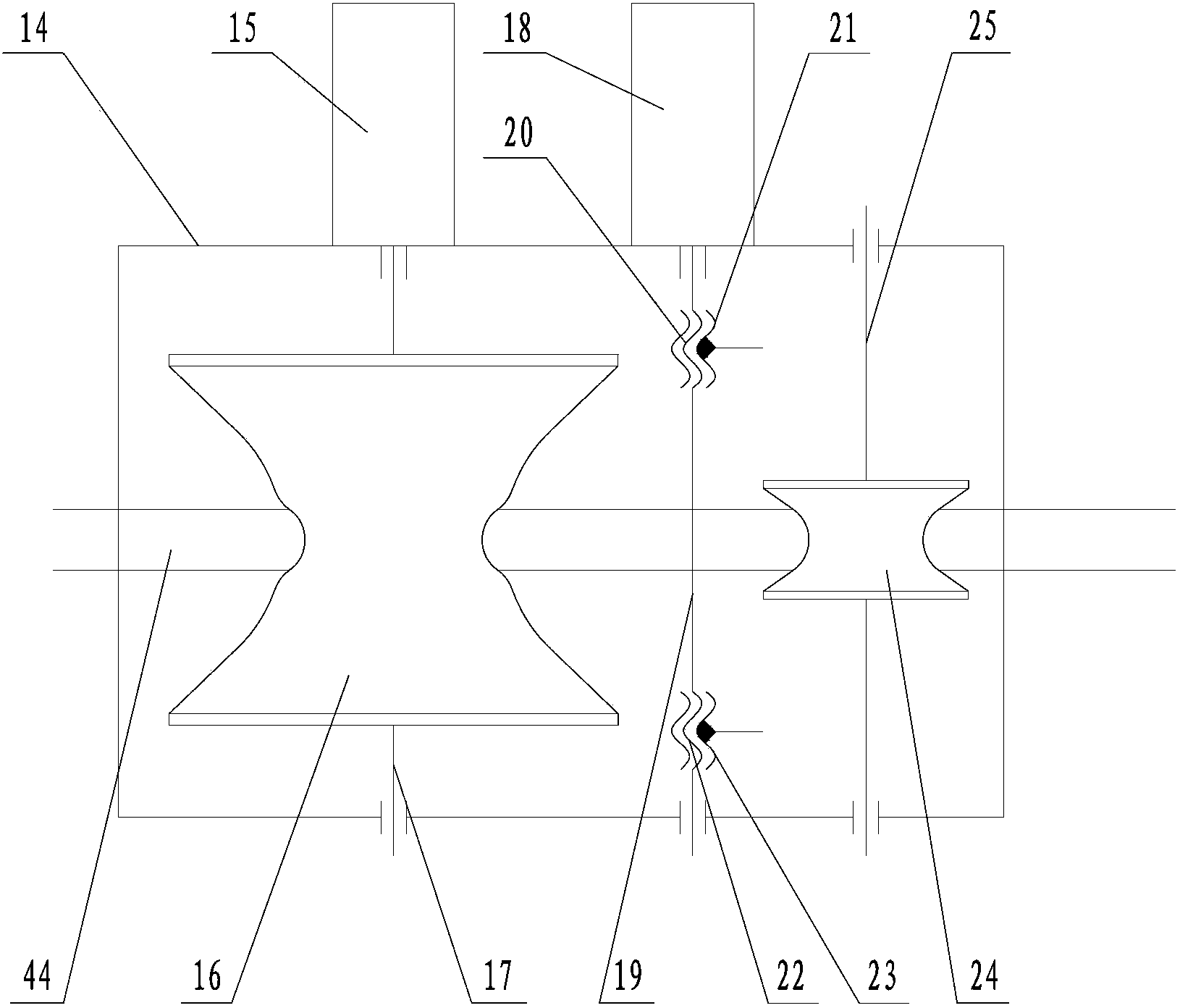

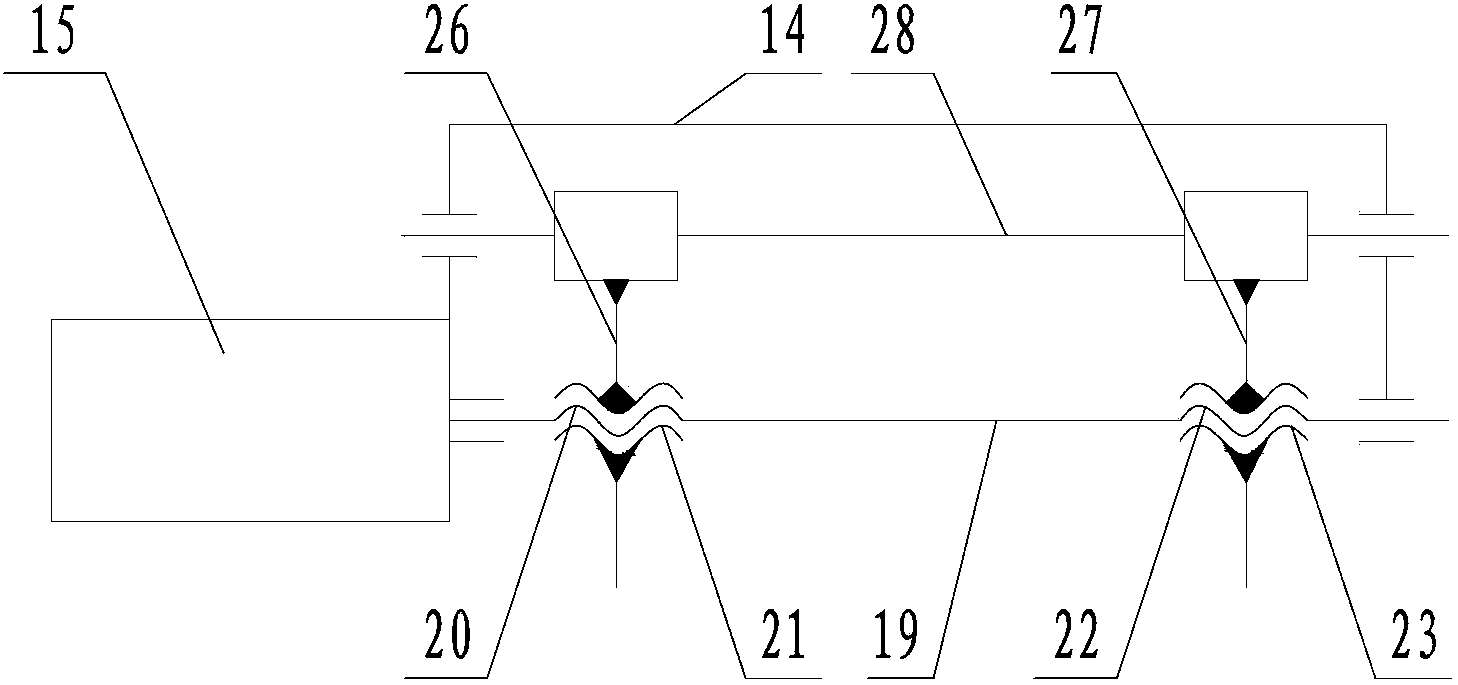

[0036] Such as figure 1 As shown, the present invention includes a front traveling clamping mechanism 1, a front pitching mechanism 2, a front elevating mechanism 3, a front slewing mechanism 4, a front four-bar linkage mechanism 5, a center of mass adjustment mechanism 6, a rear traveling clamping mechanism 8, and a rear pitching mechanism 9. The rear lifting mechanism 10, the rear slewing mechanism 11 and the rear four-bar linkage mechanism 12, wherein one end of the front and rear travel clamping mechanisms 1, 8 clamps the wire 51 and walks on the wire 51, and the other end is connected to the front and rear respectively. Rear pitching mechanism 2,9 links to each other, realizes the pitching rotation of forward and backward travel clamping mechanism by the driving of front and rear pitching mechanism 2,9; 9 are connected, and the other end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com