System, method and device for controlling liquid crystal dropping

A control system and control device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low production efficiency, low liquid crystal filling amount precision, poor display quality of liquid crystal display devices, etc., so as to improve production efficiency and prevent display Poor, the effect of improving the display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

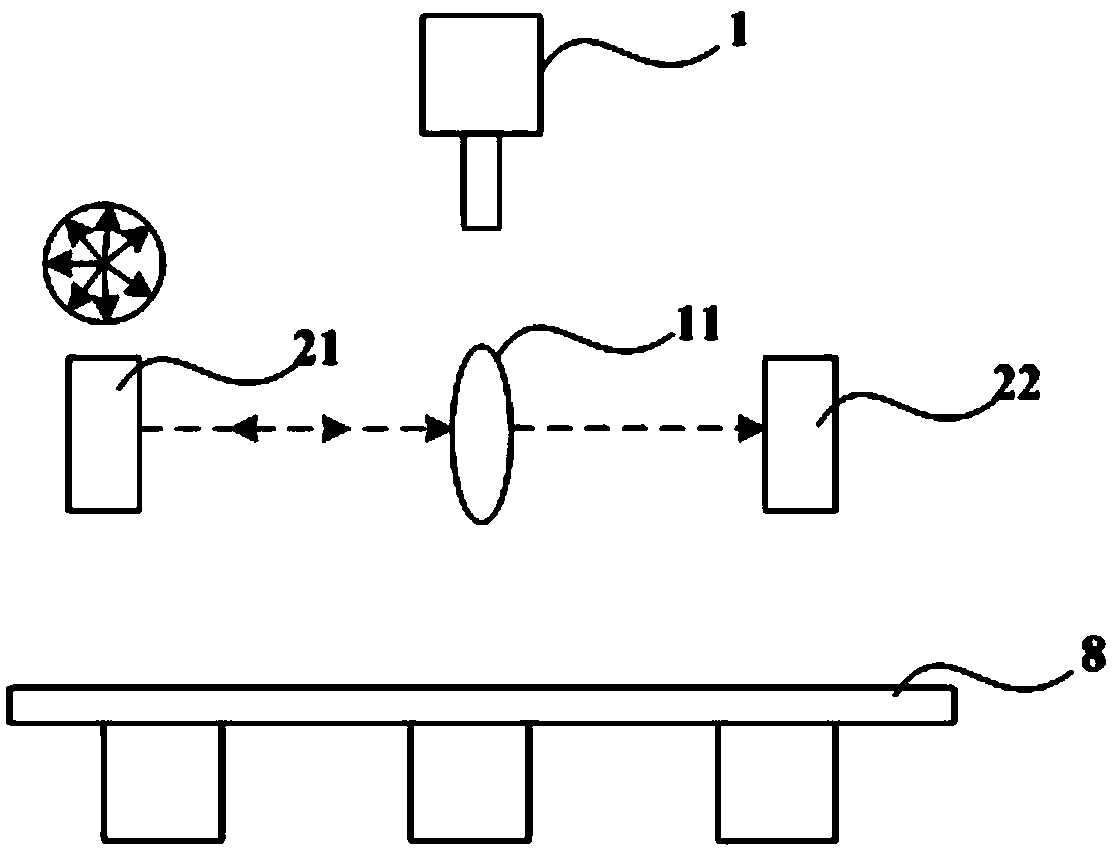

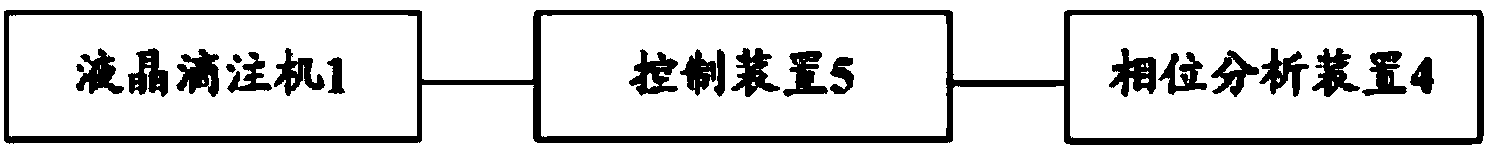

[0041] In order to improve the accuracy of the liquid crystal filling amount of the liquid crystal panel, improve the display quality of the liquid crystal display device, and improve the production efficiency of the product, the embodiments of the present invention provide a liquid crystal infusion control system, method and device. In the liquid crystal drop control system, the phase analysis device collects and calculates the current phase difference between the ordinary light and the extraordinary light, and records the contact time of the liquid crystal droplet with the incident light; The contact time of the incident light and the current phase difference between ordinary light and extraordinary light can be used to obtain the quality of the liquid crystal droplet. When the quality of the liquid crystal droplet exceeds the allowable mass range of the liquid crystal droplet, a drop stop signal is output to control the liquid crystal droplet injection machine Stop dripping,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com