Prestressed pipeline friction testing apparatus and installation method of apparatus

A prestressed pipe and test device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem that the pressure ring and the centering sleeves on both sides are difficult to stick to the centering of the centering anchor plate, which affects the construction progress, Problems such as small tension at the active end can achieve the effect of improving test efficiency and quality, reducing engineering quantity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

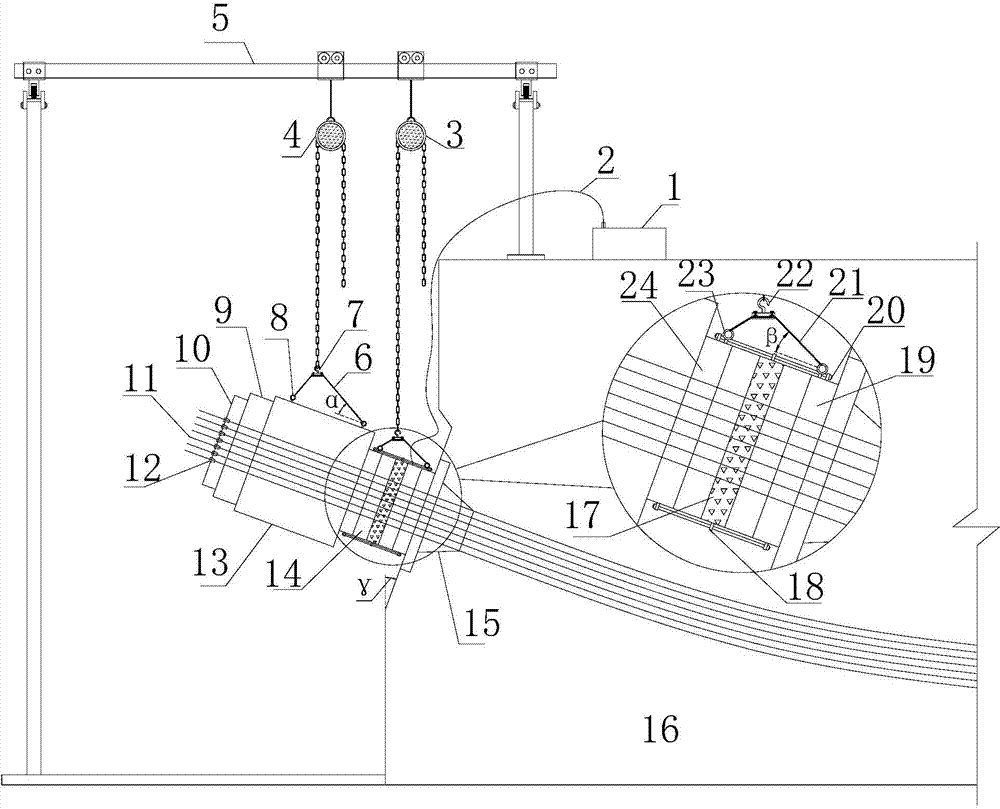

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Using the above-mentioned improved test components and installation process as a new method for the friction test of prestressed pipes of bridges, the specific steps are as follows:

[0027] Step 1: (eg figure 1 ) install the side-sliding door frame 5, and arrange the inner chain hoist 3 and the outer chain hoist 4 on the side-sliding door frame 5;

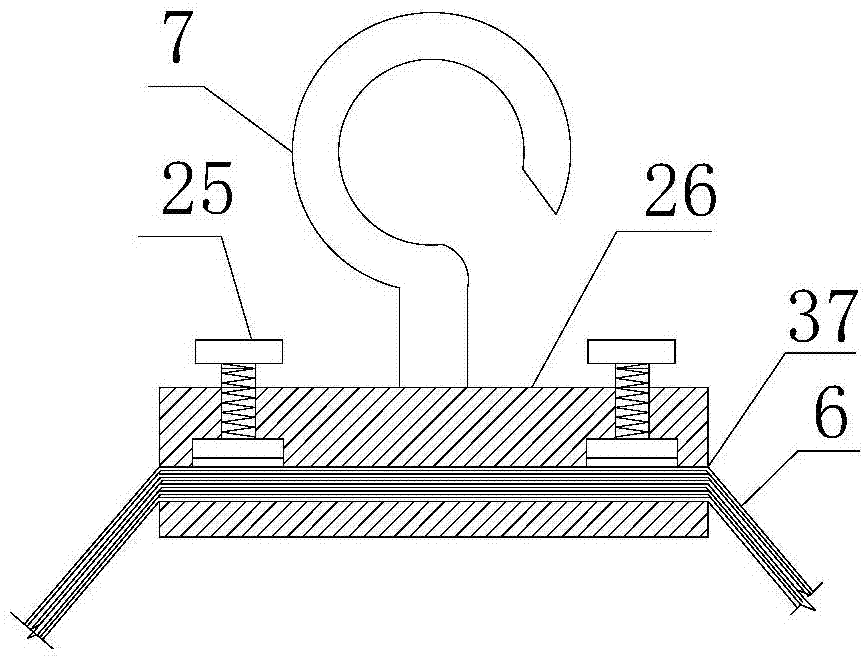

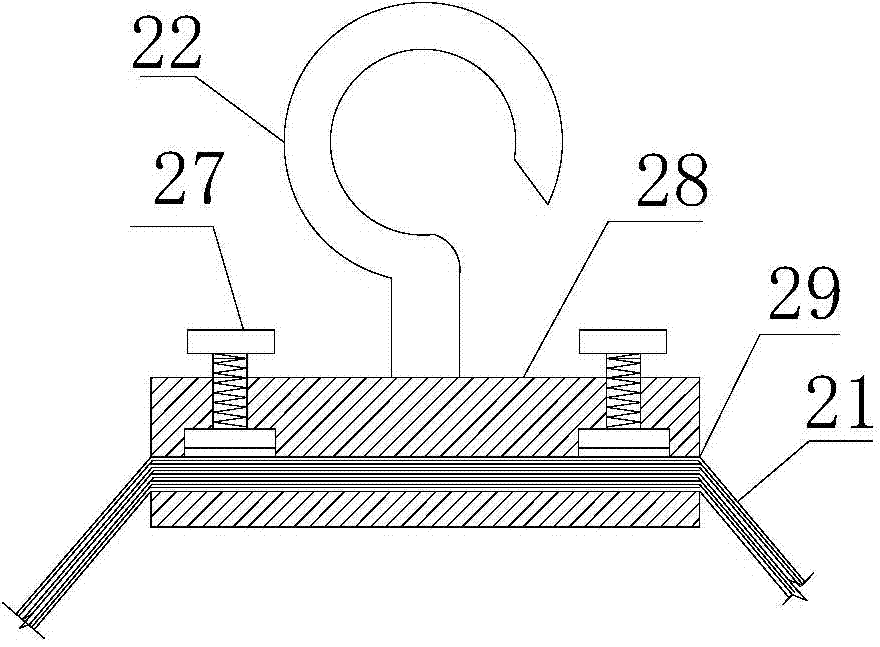

[0028] Step 2: (eg figure 1 , 4and 5) Connect the inner centering sleeve 19, the pressure ring 14 and the outer centering sleeve 24 in series with the left centering rod 31 and the right centering rod 20 to form a whole, and tighten the inner bolt lifting ring 23 to the inner centering sleeve 19 and Put the inner wire rope 21 through the inner pre-tightening hook 22 and connect it with the inner bolt ring 23, adjust the angle of the inner wire rope 21 so that the angle β is equal to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com