A Water Leakage Judgment Method for Water Cooling System

A water-cooling system and cooling water technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of system pressure and temperature, monitoring discontinuity, cooling water temperature changes, etc., to ensure continuity Effects on Sex and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

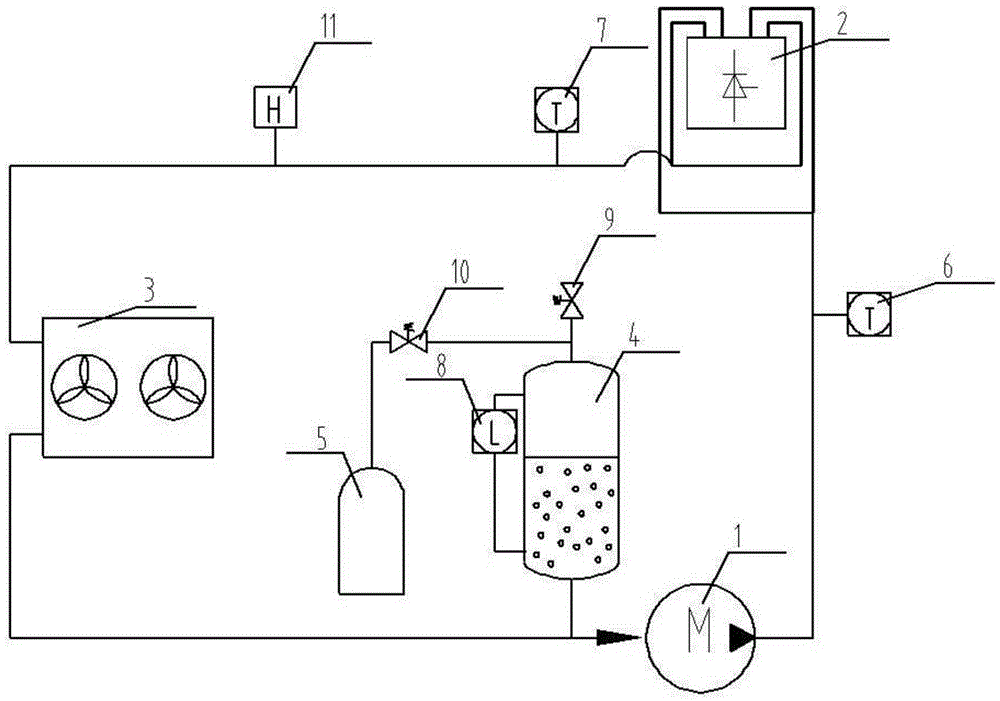

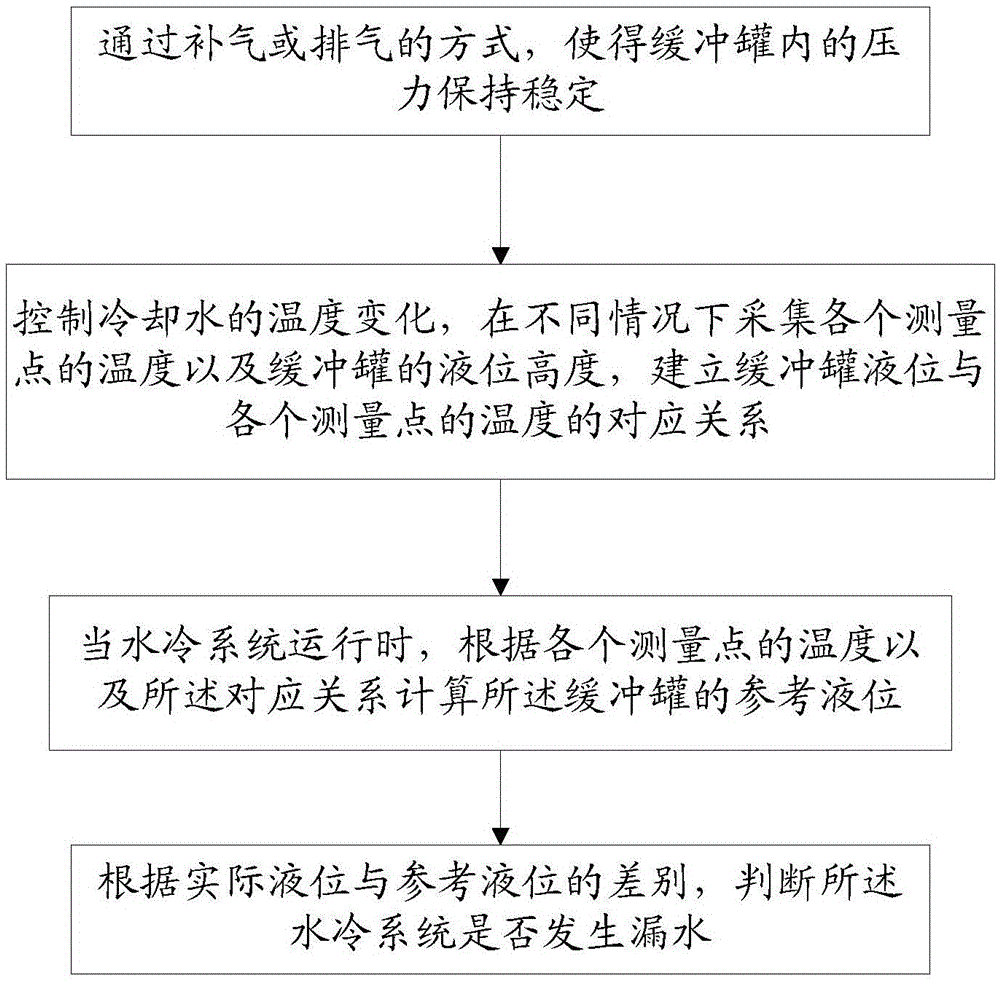

[0049] The converter valve is the core equipment of the high-voltage direct current transmission system. By sequentially connecting the three-phase alternating voltage to the direct current terminal, the desired direct current voltage is obtained and power control is realized. In order to discharge the heat generated during the working process of the converter valve in time and reduce the temperature of the converter valve, a cooling system needs to be installed. Such as figure 1 As shown, a schematic diagram of a diverter valve and its water-cooling system is given. The diverter valve 2 is surrounded by a water-cooling system, and the circulation pump 1 drives the cooling water of the entire water-cooling system to circulate to discharge heat. An inlet valve temperature sensor 6 is provided at the cooling water inlet valve, and an outlet valve temperature sensor 7 is installed at the outlet valve of the cooling water. Water dissipates heat. In addition, the water cooling sy...

Embodiment 2

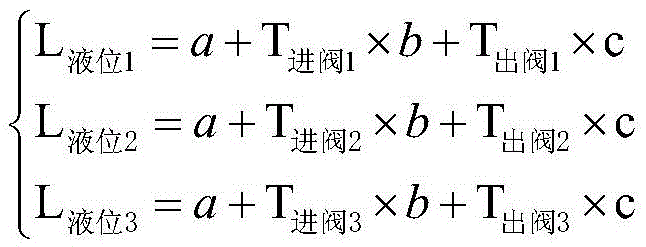

[0091] In this embodiment, when establishing the corresponding relationship between the liquid level of the buffer tank and the temperature of each measuring point, a quadratic function is used to establish the relationship, and the relationship between temperature and liquid level is selected as:

[0092] It can be obtained by solving equations and curve fitting

[0093] The relational formula.

[0094] Method 1: Solving equation method.

[0095] There are a, b in this relationship 1 , b 2 、c 1 、c 2 There are five unknowns, so five sets of data need to be collected. By starting different numbers of heater groups and setting the speed of the radiator fan, five sets of data are actually obtained.

[0096] Solve the system of equations:

[0097]

[0098] Solve for a, b 1 , b 2 、c 1 、c 2 value. The relationship can be determined.

[0099] Method 2: Curve Fitting Method

[0100] Several sets of data can be collected for multiple sets of data:

[0101] Calculate...

Embodiment 3

[0118] In this embodiment, a neural network is used to establish the corresponding relationship between the liquid level of the buffer tank and the temperature of each measurement point, and the specific method is as follows:

[0119] First, the pressure in the buffer tank is kept stable by means of air supply or exhaust.

[0120] Then, the temperature change of the cooling water is controlled, and the temperature of each measurement point and the liquid level of the buffer tank are collected under different conditions. In the case of confirming that the system is not leaking, by changing the number of heating groups of the heater and the frequency of the cooling fan, different temperatures and corresponding liquid level values are obtained, and these values are used as input samples to train the neural network, here The neural network can use the neural network model in the prior art to obtain a suitable neural network model through the sample training method, thereby est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com