Hand digging type pipe jacking construction device and method for sediment and sludge areas

A construction device and construction method technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of automatic collapse at the entrance of tool pipes, difficulties in correcting deviations in hand-dug pipe jacking construction, and pipe jacking. Construction failure and other problems, to achieve a good excavation environment, improve strength, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

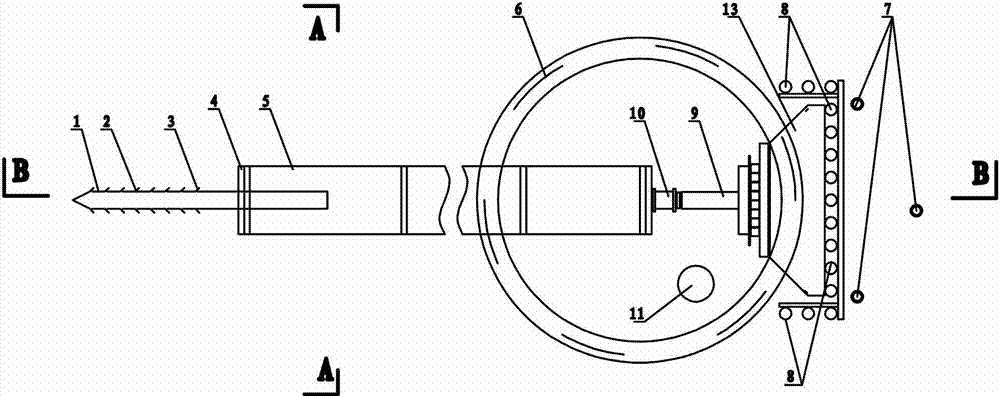

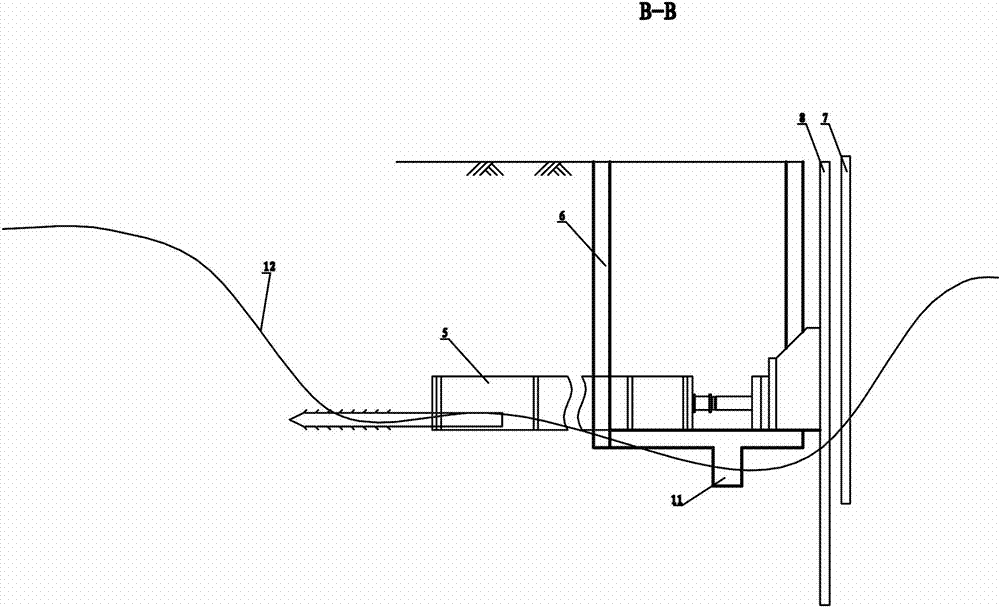

[0028] Such as Figure 2~4 Among them, a hand-dug type pipe jacking construction device in mud, sand and silt areas, including a tool pipe 5, a jack 9 is provided between the tool pipe 5 and the concrete back, and a water seepage pipe 1 is provided at the front end of the tool pipe 5, and the water seepage pipe 1 One part passes through the pipe cap 4, and the other part is located in the tool pipe 5. The front end of the seepage pipe 1 is tapered to facilitate jacking, and the rear end is open to facilitate drainage. On the wall of the seepage pipe 1, there are multiple Seepage hole 2. With this structure, groundwater enters the seepage pipe 1 through the water seepage hole 2 and gathers to form a groundwater funnel, thereby reducing the groundwater level at the front end of the tool pipe 5, as image 3 , 4 shown in . This optimizes the operating conditions for hand digging pipe jacking construction.

[0029] The preferred solution is as figure 2 , 3 Among them, a wate...

Embodiment 2

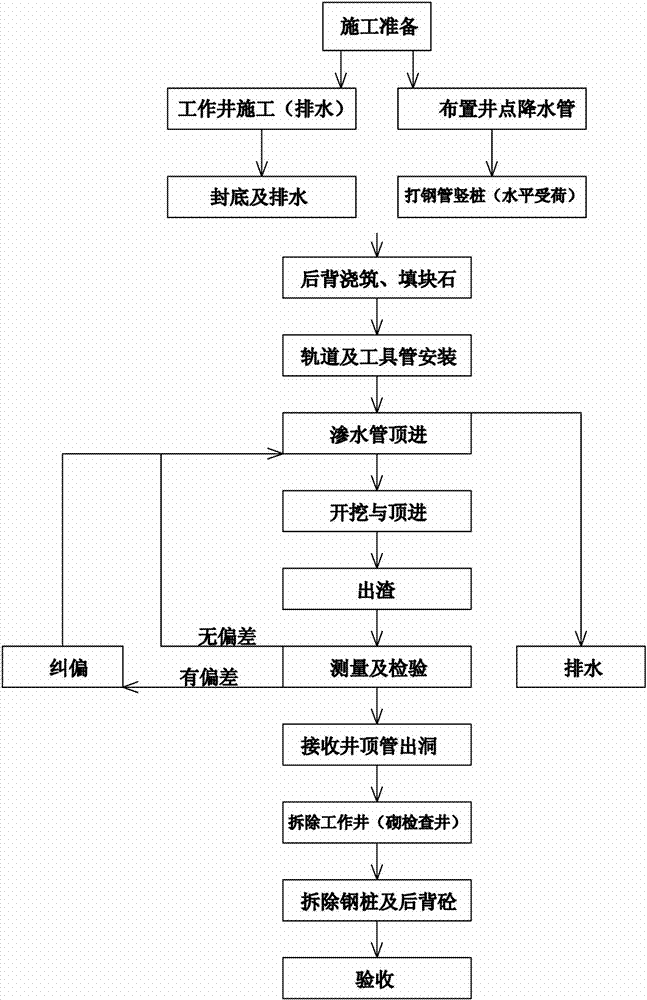

[0035] Such as Figure 1~4 Shown in, a kind of method that adopts the construction device of above-mentioned embodiment to carry out the method for hand-dug type pipe jacking construction in mud sand silt area, comprises the following steps:

[0036] 1. A row of vertical loaded piles 8 are driven into the working well on the side facing the tool pipe 5; the bearing capacity of the concrete back 13 is improved by driving the loaded piles 8;

[0037] Two, pour the back 13 before the loaded pile 8, install the jack 9 and the top iron 10;

[0038] 3. At the inner bottom of the front end of the tool pipe 5, drive one or more seepage pipes 1, only one is shown in the figure, and the groundwater in the soil near the mouth of the tool pipe seeps out in advance through the seepage pipe 1, so that the tool pipe The mouth is within the scope of the precipitation funnel;

[0039] 4. Every time the tool pipe 5 is jacked up one stroke, the seepage pipe 1 is jacked up one stroke in advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com