A rapid cavitation test device and test method for porous nozzles of diesel engines

A technology of porous nozzle and cavitation test, which is applied in the direction of fuel injection device, engine test, machine/structural component test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

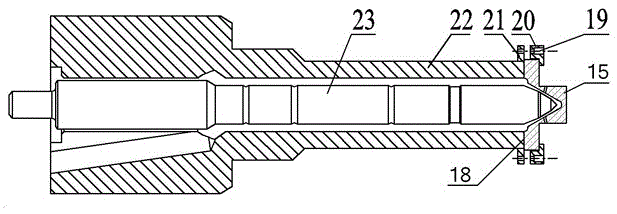

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

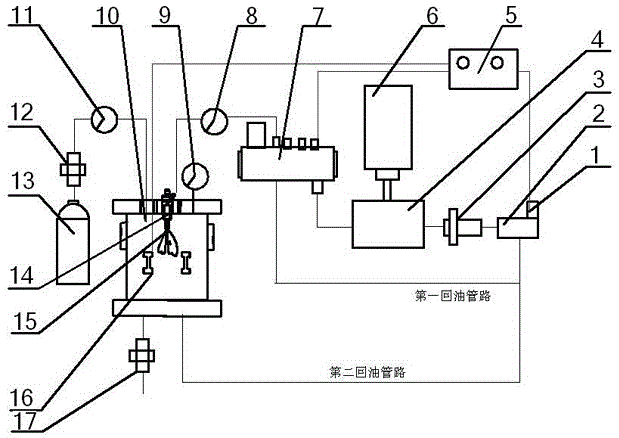

[0024] The structure of the fast cavitation test device of a kind of diesel engine porous nozzle of the present invention is as follows figure 1 As shown, including fuel supply system, injection system and back pressure system.

[0025] The fuel supply system includes a fuel tank 2, a fuel filter 3, a high-pressure fuel pump 4 and a common rail pipe 7 connected in sequence. The fuel tank 2 is equipped with a first heating tile 1 and a temperature sensor. The high-pressure fuel pump 4 is connected to a motor 6 for a total of The rail pipe 7 is provided with a temperature sensor. The system mainly provides continuous and stable high-pressure fuel for the whole test device. After the fuel is pressurized by the high-pressure pump from the fuel tank, it becomes high-pressure fuel, and then the fuel enters the common rail pipe. to the fuel injection system. The fuel suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com