A kind of preparation method of yttrium oxycalcium borate crystal (ycob) high laser damage threshold anti-reflection film

A calcium yttrium triborate, laser damage threshold technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc. Reduce and other problems, achieve good economic benefits, high damage threshold, and reduce the effect of microscopic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail by specific examples, as follows:

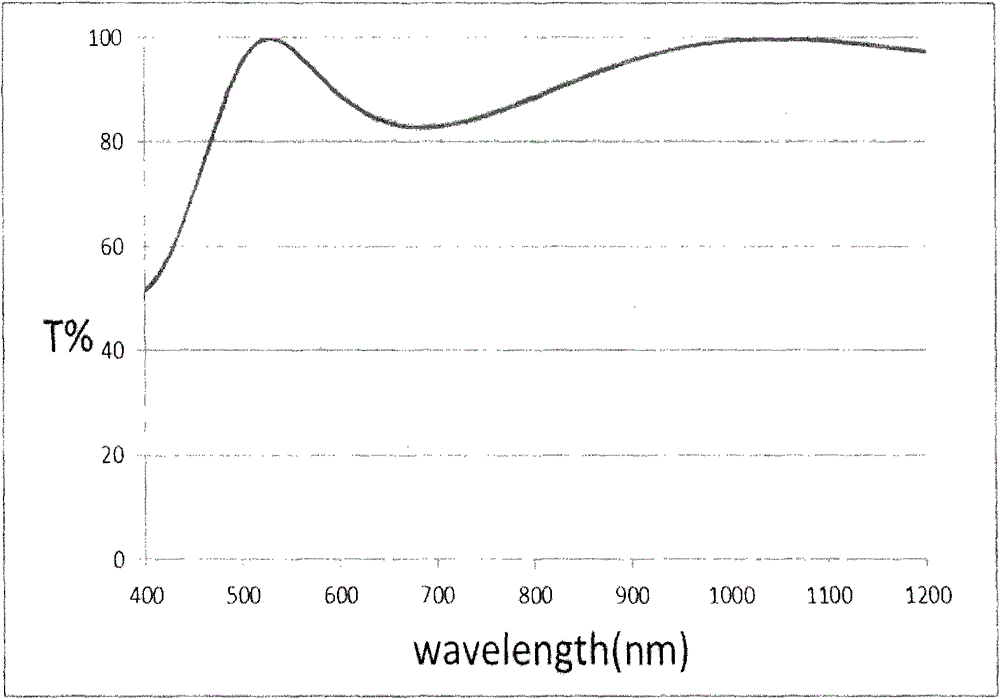

[0026] YCOB crystal 1064nm and 527nm dual-wavelength anti-reflection coating coating

[0027] 1. The YCOB crystal size of the plated sample is 10*10*3mm. The structure of the film system is: SL(HL)^3A, S is the substrate YCOB crystal, A is air, and H is the high refractive index material HfO 2 , L is the low refractive index material SiO 2 , the thickness of each film is 190nm / 54.8nm / 62.53nm / 119nm / 22nm / 165.54, the coating equipment is Japan Optical Chi coating machine OTFC-1800, and the configuration ion source is 17cm radio frequency ion source.

[0028] 2. Plating is performed according to the aforementioned process steps, and the conventionally polished YCOB substrate is etched with an etching solution prepared by mixing hydrofluoric acid and deionized water (volume ratio 1:20), and the etching time is 30 minutes. The substrate after chin etching was cleaned with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com