Emergency shutdown system of gas cut-off valve

A technology for shutting down systems and shut-off valves, applied to blast furnace parts, furnaces, heating furnaces, etc., can solve problems such as gas leakage, inability to realize remote closing of gas shut-off valves, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

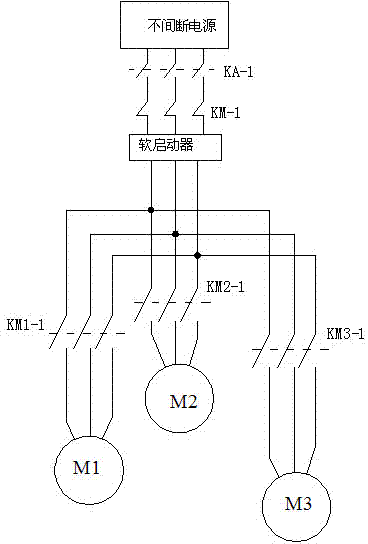

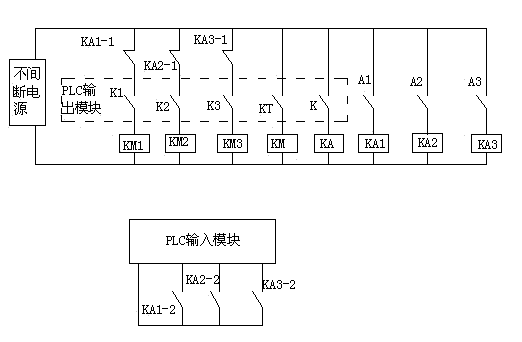

[0015] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0016] It can be seen from the accompanying drawings that an emergency closing system for a gas shut-off valve of this program includes an uninterruptible power supply, and the uninterruptible power supply is connected to the gas shut-off valve through a soft starter, and has a switch input module and a switch The PLC controller of the output module has three valve emergency switches K1, K2, K3, which correspond to three gas cut-off valves M1, M2, M3 respectively, and are used to control the gas of the three hot blast stoves.

[0017] The first valve emergency switch K1 and the first emergency cut-off relay KM1 are connected in series to the uninterruptible power supply. The normally open contact KM1-1 of the first emergency cut-off relay is connected in series with the first gas cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com