Maotai flavor type mixed liquor and preparation method thereof

A sauce-flavored wine preparation technology, which is applied in the field of wine preparation, can solve problems such as high alcohol content, strong stimulation, and lack of aroma, and achieve the effect of single taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

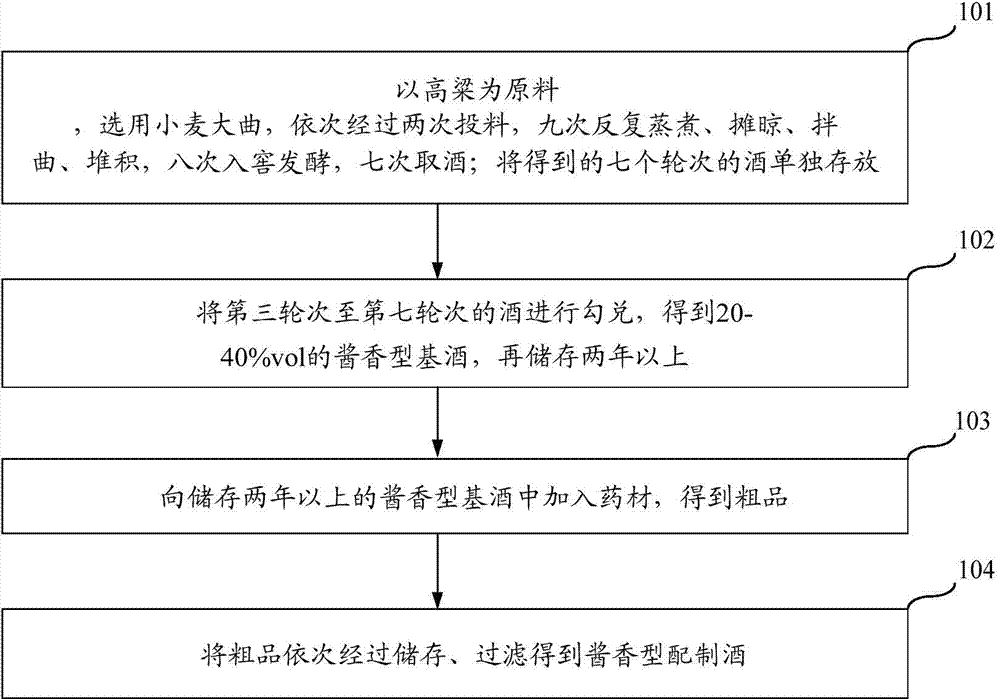

[0027] A preparation method of sauce-flavored wine, such as figure 1 shown, including the following steps:

[0028] Step 101: Using sorghum as the raw material for wine making, wheat Daqu was selected, fed twice in sequence, boiled nine times, spread out, mixed with koji, and piled up, put into the cellar for fermentation eight times, and took wine seven times; the obtained seven rounds The second wine is stored separately.

[0029] Step 102: Blend the wines from the third round to the seventh round to obtain a 20-40% vol Maotai-flavored base wine, and store them for more than two years.

[0030] Step 103: adding medicinal materials to the Maotai-flavored base wine stored for more than two years to obtain a crude product.

[0031] Step 104: The crude product is sequentially stored and filtered to obtain the sauce-flavored wine.

[0032] Wherein, the raw materials referred to in the two feeds in step A are sorghum and wheat Daqu (Daqu made from wheat).

[0033] For the prep...

Embodiment 2

[0049] The preparation method of the Maotai-flavored mixed wine with the yellow grass as the raw material comprises the following steps:

[0050] The first step is to prepare the sauce-flavored base wine:

[0051] Using sorghum as the raw material for wine making, select ultra-high temperature Daqu with a saccharification power of 40-80 mg / g h and a liquefaction power of 0.8-1.0 g / g h (the highest fermentation temperature reaches 68°C), and produce it as Maotai-flavored liquor The process involves feeding grain twice, cooking, drying, and mixing koji for nine times, then stacking at a high temperature of 45-50°C, eight times for fermentation in cellars, and seven times for wine extraction.

[0052] After each round of extraction, the wine is stored separately, and then 3-7 rounds of wine are selected and blended to produce a low-alcohol sauce-flavored base wine with an alcohol content of 20-40%vol.

[0053] Put the above-mentioned low-alcohol sauce-flavored base wine into a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glycation power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com