Production method of dried sweet potatoes

A production method and technology of dried sweet potatoes, which are applied in the field of food processing, can solve the problems of single taste of dried sweet potatoes, and achieve the effect of being beneficial to human health and having a simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

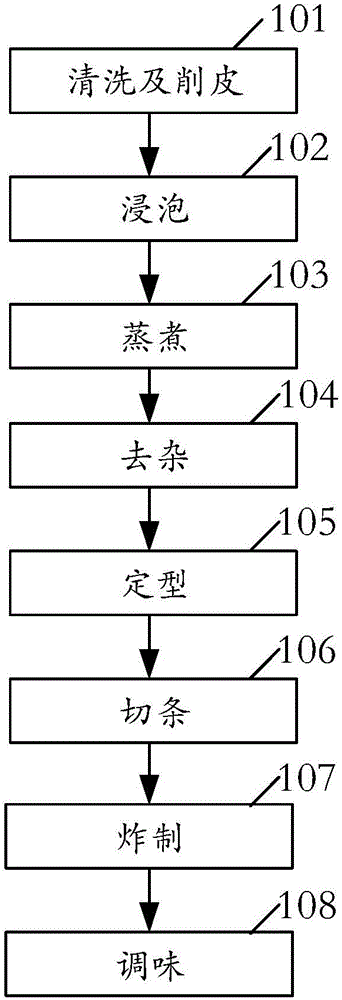

[0018] The embodiment of the present invention provides a kind of production method of dried sweet potato, such as figure 1 shown, including:

[0019] Step 101, cleaning and peeling: wash the air-dried sweet potatoes with clean water to clean the surface; peel the cleaned sweet potatoes to remove skin fibers, diseased spots, black spots and bitter threads;

[0020] Step 102, soaking: put the wild jujube into boiling water, steam for 1 hour, take the supernatant after steaming the wild jujube for use, put the cleaned sweet potato into the supernatant, soak it, take it out after 5 hours and let it cool;

[0021] Step 103, steaming: steaming the soaked sweet potatoes under high pressure until the sweet potatoes are pureed, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com