Technique method for producing gasoline by using methanol through one-step method

A process method, methanol technology, applied in the field of one-step methanol production of gasoline, which can solve the problems of high operating costs, large investment, and a large number of reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

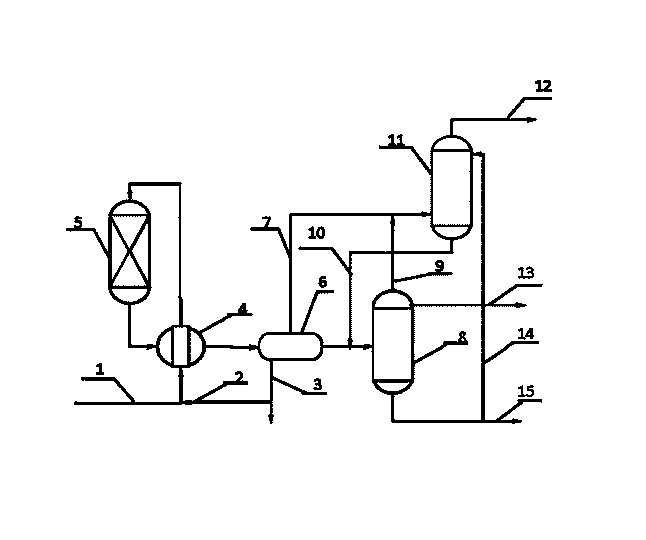

Image

Examples

Embodiment 1-9

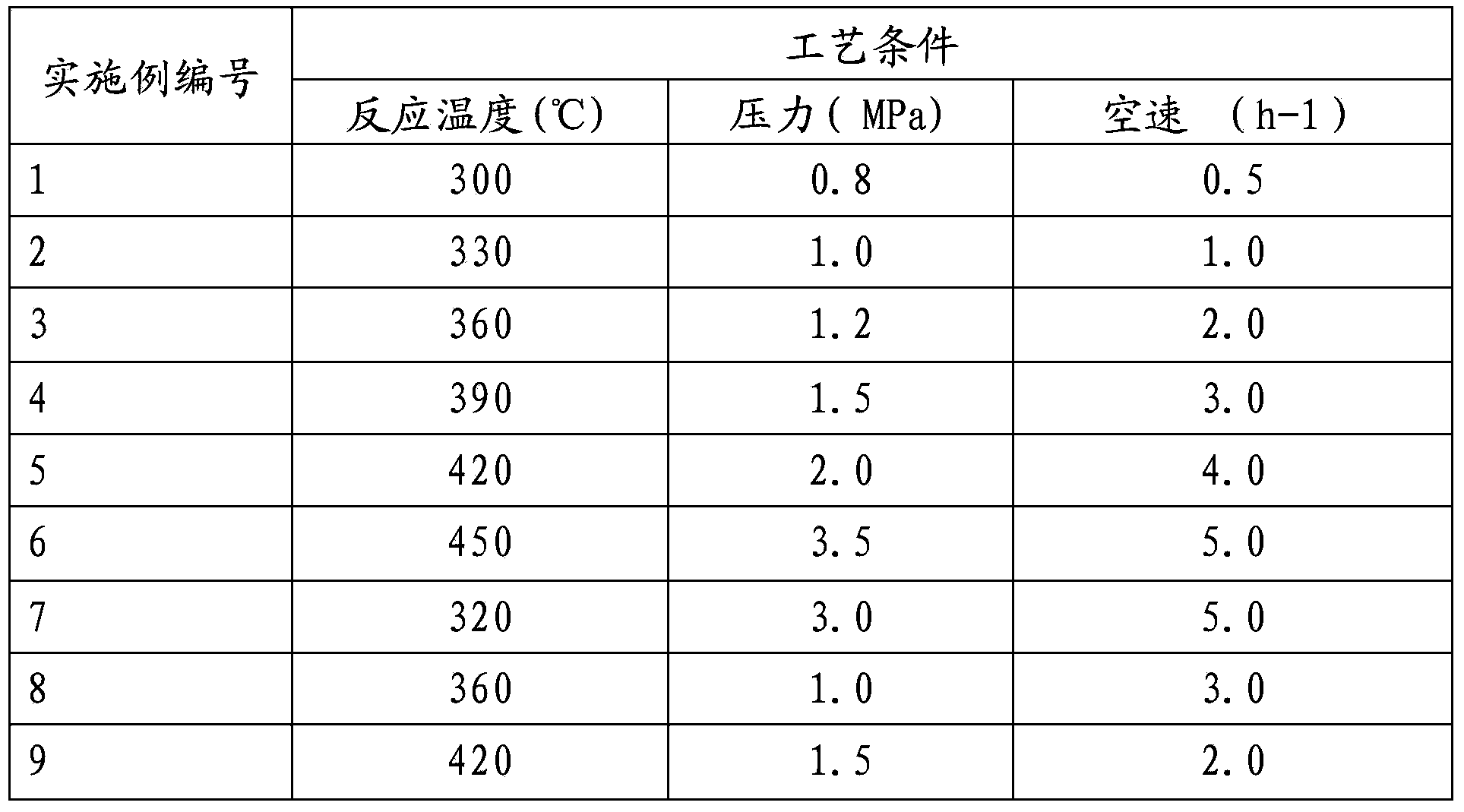

[0041] In the fixed-bed stainless steel reactor that 500 milliliters of special catalyzers are housed, experiment is carried out according to the method provided by the present invention and condition, see Table 1 for experimental operation condition, be equipped with high-pressure separator, stabilizer, absorber, product collection device.

[0042] Table 1 Experimental operating conditions

[0043]

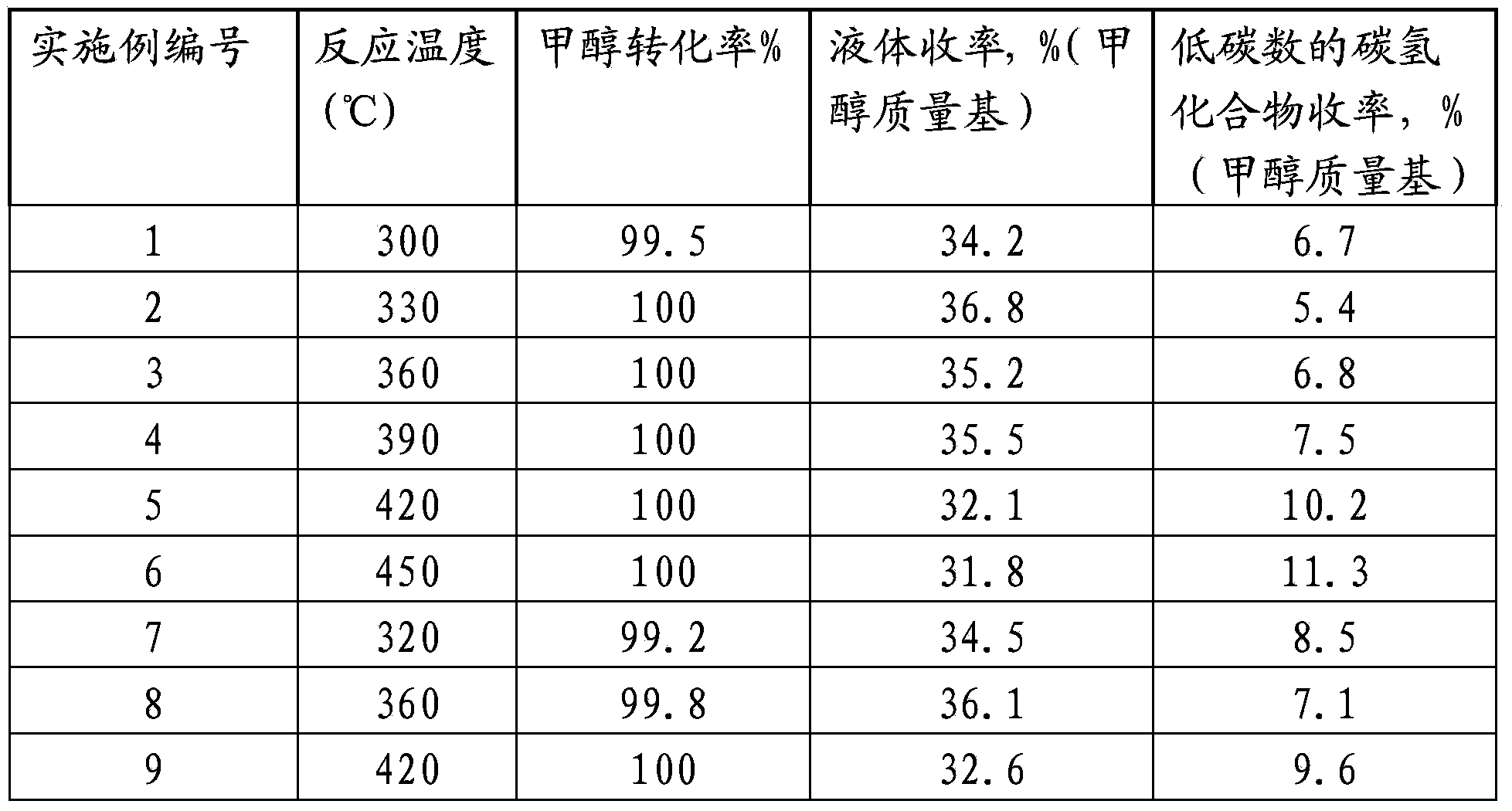

[0044] Through the implementation of the technical solution of the present invention, please refer to Table 2 for the finally obtained experimental results of the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com