Multistage ferric-carbon microelectrolysis coupled Fenton oxidation bed reactor

An iron-carbon micro-electrolysis and reactor technology, applied in the field of water treatment, can solve the problems of substandard total nitrogen and chromaticity, unsatisfactory removal of organic pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

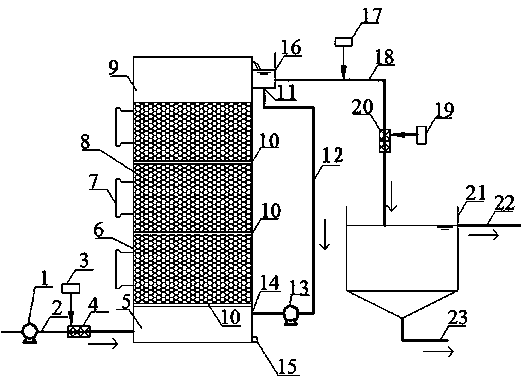

[0013] The specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0014] A multi-stage iron-carbon micro-electrolysis coupled Fenton oxidation bed reactor, including a lifting pump 1, a water inlet pipe 2, a hydrogen peroxide dosing device 3, a water inlet pipe mixer 4, a water distribution chamber 5, and a multi-stage iron-carbon micro-electrolysis reactor Electrolytically coupled Fenton oxidation bed reactor body 6, refueling port 7, elemental iron and granular activated carbon mixture layer 8, effluent clarification area 9, sieve plate water distribution system 10, sludge discharge port 15, reactor outlet channel 16, The outlet pipe 18 and the sedimentation tank, the sedimentation tank includes a sedimentation tank body 21, an outlet pipe 22 and a mud discharge pipe 23, one end of the water inlet pipe is connected with the raw water of coking wastewater and the outlet water after the conventional common biol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com