Method for producing aluminium hypophosphite by adopting reaction extrusion process

A technology of reactive extrusion and aluminum hypophosphite, which is applied in the direction of hypophosphorous acid and phosphorus oxyacid, can solve the problems of lower decomposition temperature of aluminum hypophosphite and large particle size of aluminum hypophosphite, so as to reduce energy consumption and production cost Low, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for producing aluminum hypophosphite using a reactive extrusion process, including the following steps:

[0035] (1) Mix 5280g of sodium hypophosphite and 3420g of aluminum sulfate uniformly, then add the mixture into a twin-screw extruder set at 50°C for reactive extrusion; after reactive extrusion, a white mud-like product is obtained;

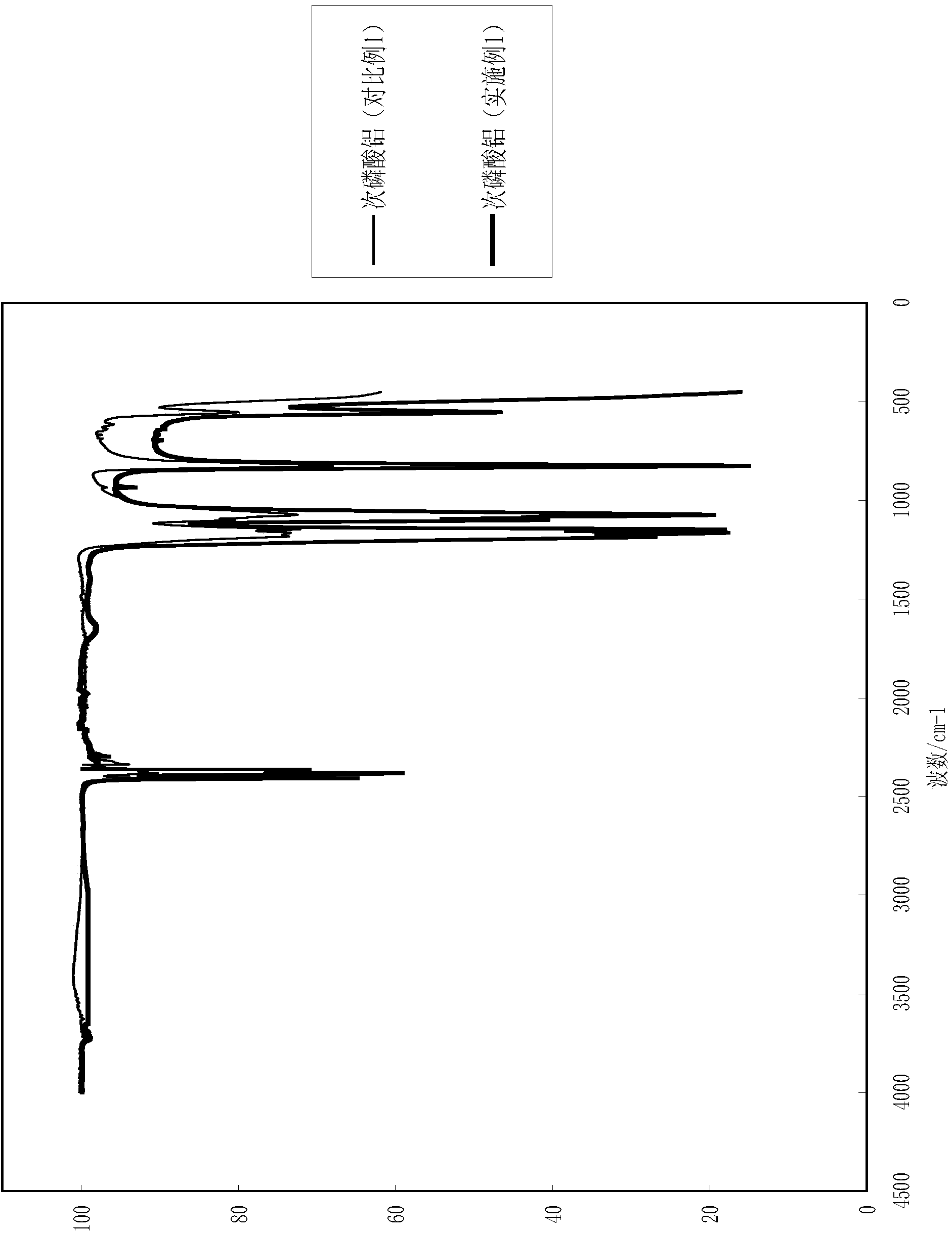

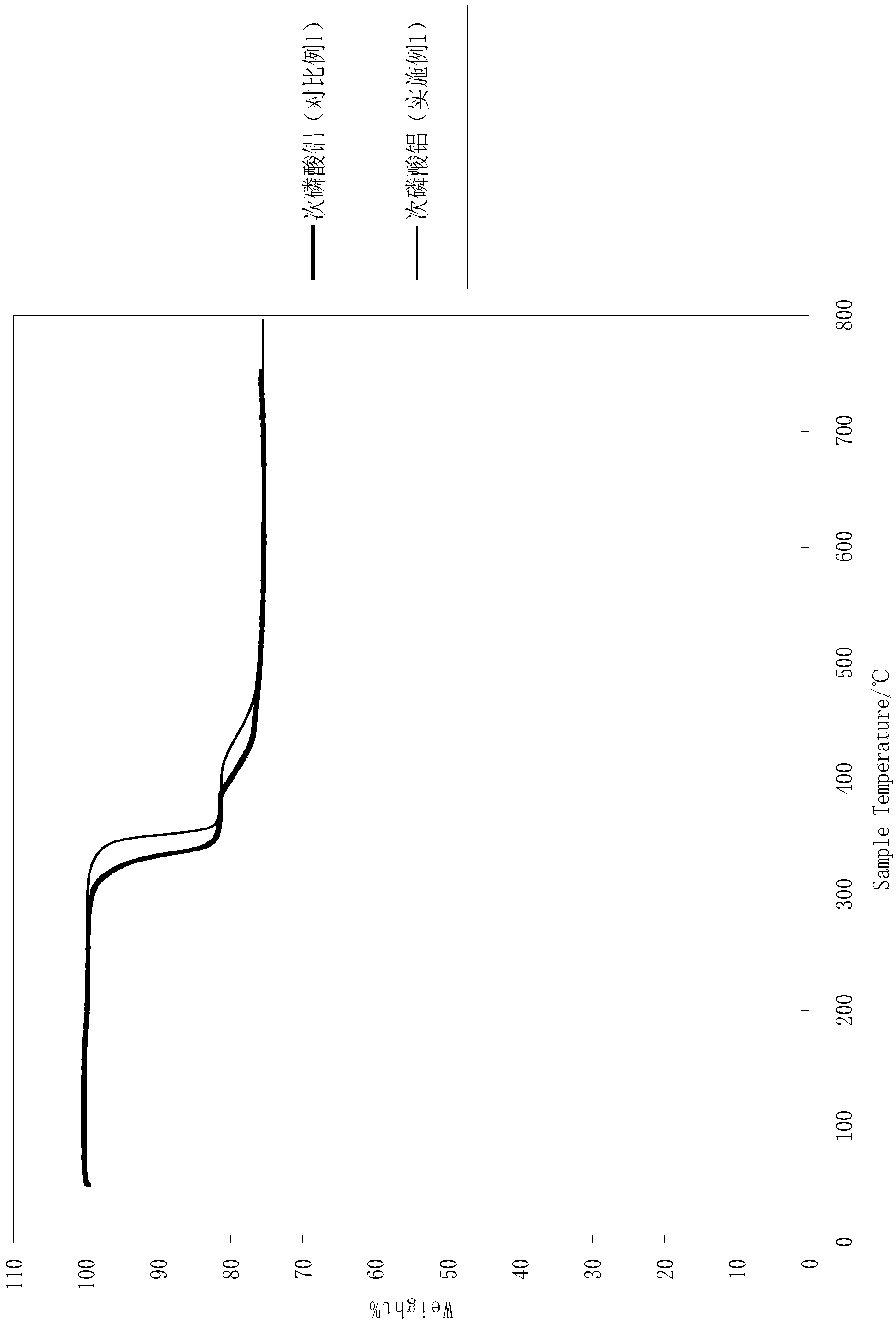

[0036] (2) The product of step (1) is sealed and stored in an environment of 50° C., and matured for 24 hours; then the product is washed, filtered and dried to obtain white powdery aluminum hypophosphite. After testing, the yield of the product obtained in this example was 98%. The particle size analysis of the obtained aluminum hypophosphite is shown in Table 1, and the infrared detection spectrum is shown in figure 1 , See the thermal weight loss chart figure 2 And table 2.

Embodiment 2

[0047] A method for producing aluminum hypophosphite using a reactive extrusion process, including the following steps:

[0048] (1) Mix 2490g of ammonium hypophosphite and 2130g of aluminum nitrate uniformly, then add the mixture into a twin-screw extruder set at 70°C for reactive extrusion; after reactive extrusion, a white mud-like product is obtained;

[0049] (2) The product of step (1) is sealed and stored in an environment of 80° C., and matured for 4 hours; then the product is washed, filtered and dried to obtain white powdery aluminum hypophosphite. After testing, the yield of the product obtained in this example was 97%. The particle size analysis of the obtained aluminum hypophosphite is shown in Table 3, and the infrared detection spectrum is shown in image 3 , See the thermal weight loss chart Figure 4 And Table 4.

[0050] Table 3 Particle size analysis of aluminum hypophosphite prepared in Example 2 and Comparative Example 1

[0051]

Median diameter

Volume ave...

Embodiment 3

[0056] A method for producing aluminum hypophosphite using a reactive extrusion process, including the following steps:

[0057] (1) Mix 3122g potassium hypophosphite and 1333g aluminum chloride uniformly, then add the mixture into a twin-screw extruder set at 60°C for reactive extrusion; after reactive extrusion, a white mud-like product is obtained;

[0058] (2) The product of step (1) is sealed and stored in an environment of 60° C., and matured for 12 hours; then the product is washed, filtered and dried to obtain white powdery aluminum hypophosphite. After testing, the yield of the product obtained in this example was 98%. The particle size analysis of the obtained aluminum hypophosphite is shown in Table 5, and the infrared detection spectrum is shown in Figure 5 , See the thermal weight loss chart Image 6 And table 6.

[0059] Table 5 Particle size analysis of aluminum hypophosphite prepared in Example 3 and Comparative Example 1

[0060]

Median diameter

Volume averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com