Pneumatic control system in elevator lift car

An elevator car and air pressure control technology, which is applied to elevators, elevators, transportation and packaging in buildings, etc., can solve problems such as changes in the atmospheric pressure of the car, the size of the blower is not clearly indicated, and the rapid change of air pressure cannot be achieved. Structure, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

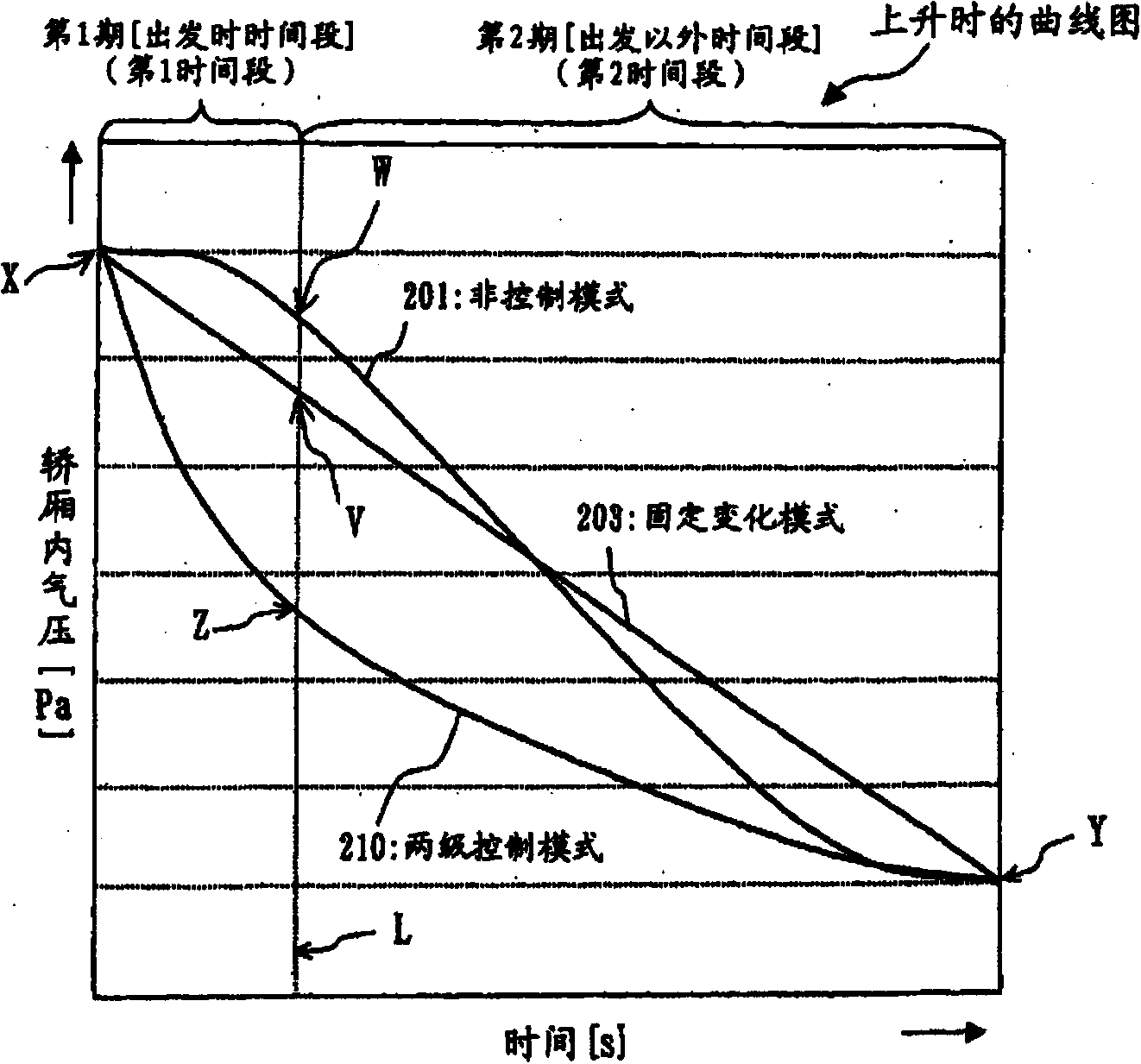

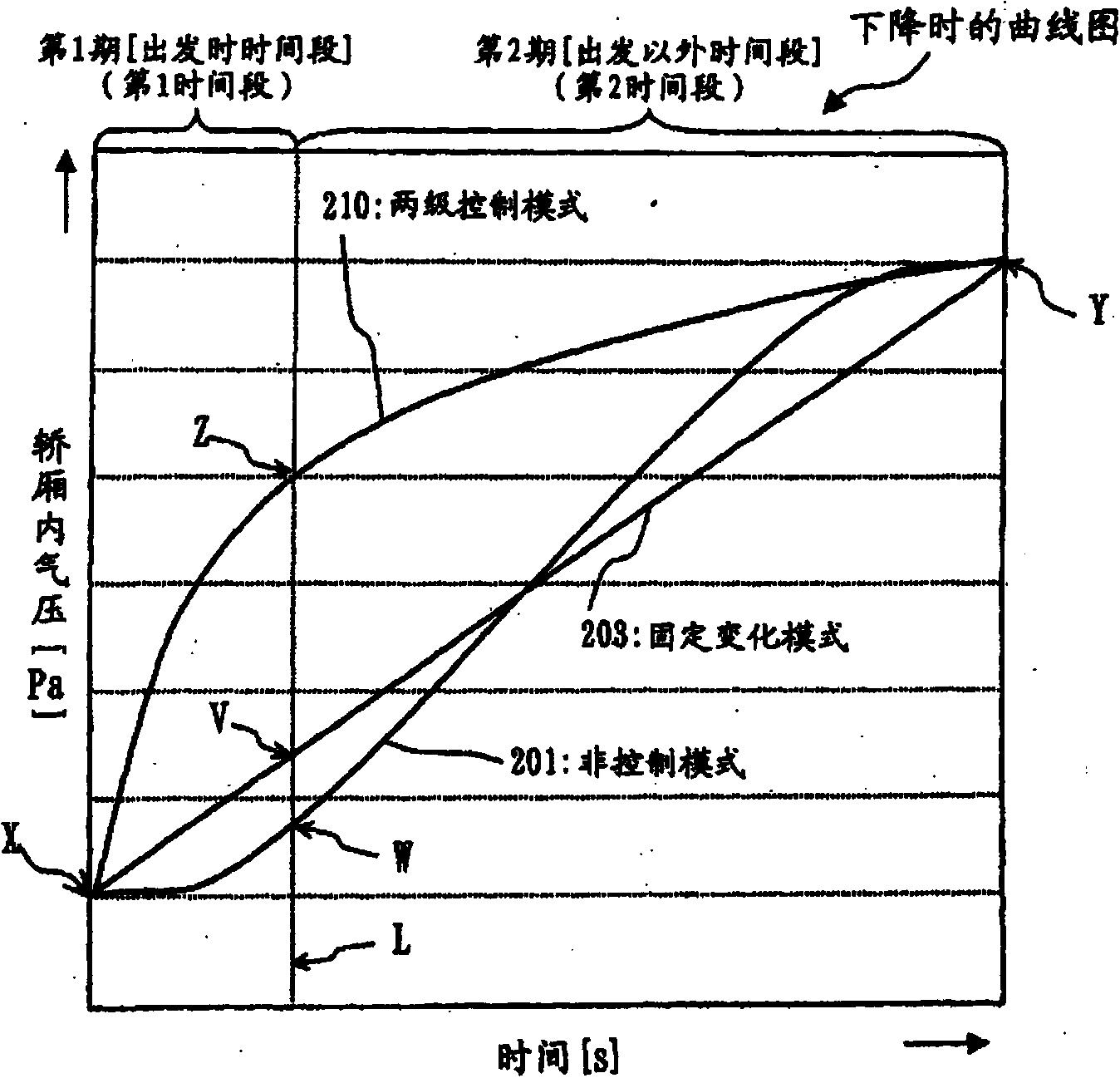

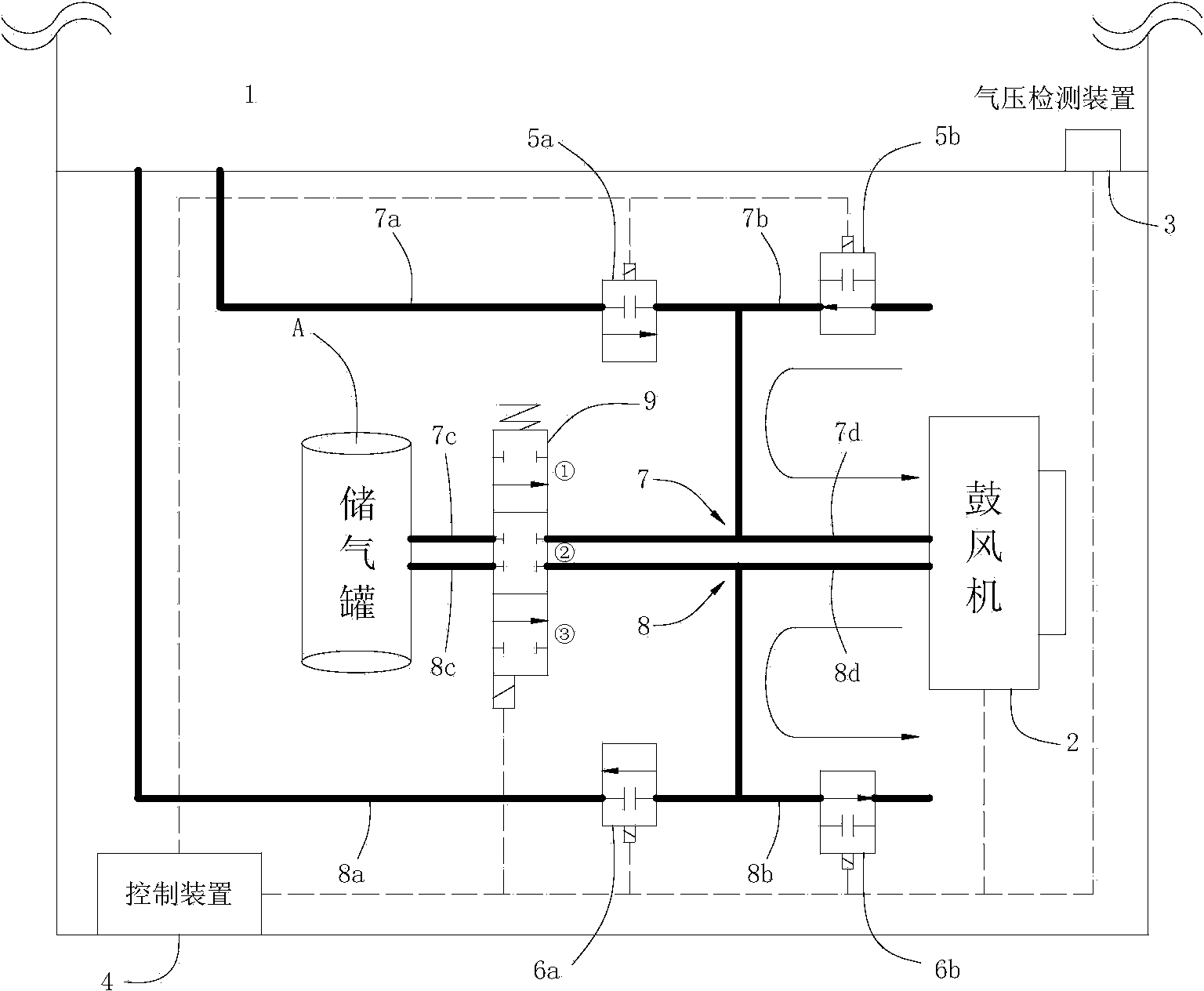

[0060] Figure 3 to Figure 9 Embodiment 1 of the air pressure control system in an elevator car according to the present invention is shown.

[0061] Such as Figure 3 to Figure 9 As shown, the air pressure control system in the elevator car of the present embodiment for controlling the air pressure in the elevator car 1 is arranged at the bottom of the elevator car 1, and the system has: a blower 2 with a small wind force, which is arranged The bottom of the elevator car 1, and continuously generates wind pressure in one direction when the elevator is running; an air storage tank A, whose function is to discharge the air in the elevator car 1 and reduce the air pressure in the elevator car 1 , or used to fill air into the elevator car 1 to increase the air pressure in the elevator car 1; a three-position four-way reversing valve 9, the reversing valve controls its position through the control device 4; decompression Use the piping group 7, which has a first decompression pi...

Embodiment approach 2

[0084] Such as Figure 12 to Figure 19 As shown, the air pressure control system in the elevator car of the present embodiment for controlling the air pressure in the elevator car 1 is arranged at the bottom of the elevator car 1. Wind pressure is continuously generated in one direction during operation; two air storage tanks (B, C), one of the two air storage tanks is the air storage tank B used to discharge the air in the elevator car 1, which can reduce The effect of the air pressure in the elevator car 1, the other of the two air storage tanks is the air storage tank C used to fill the elevator car 1 with air, which plays the role of increasing the air pressure in the elevator car 1; The pressure piping group 7 has a fifth decompression piping 7e, one end of which is open in the elevator car 1, the other end connected to one end of the decompression air tank B, and a second decompression piping 7e, one end of which is open to the atmosphere. The piping 7b, and the sixth d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com