Full-automatic paper mounting machine paper feeding mechanism capable of conveying short paper pieces

A paper feeding mechanism, short size technology, applied in the direction of object supply, pile separation, thin material handling, etc., can solve the problem of not being able to process short size paper, and achieve the effect of facilitating paper transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

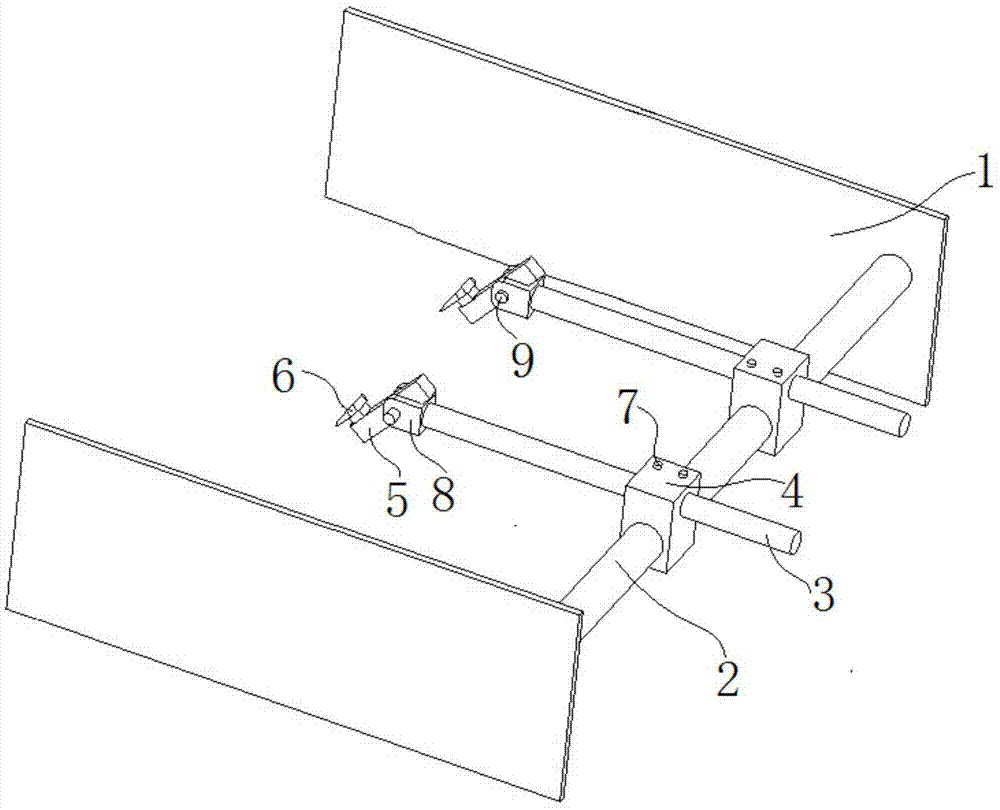

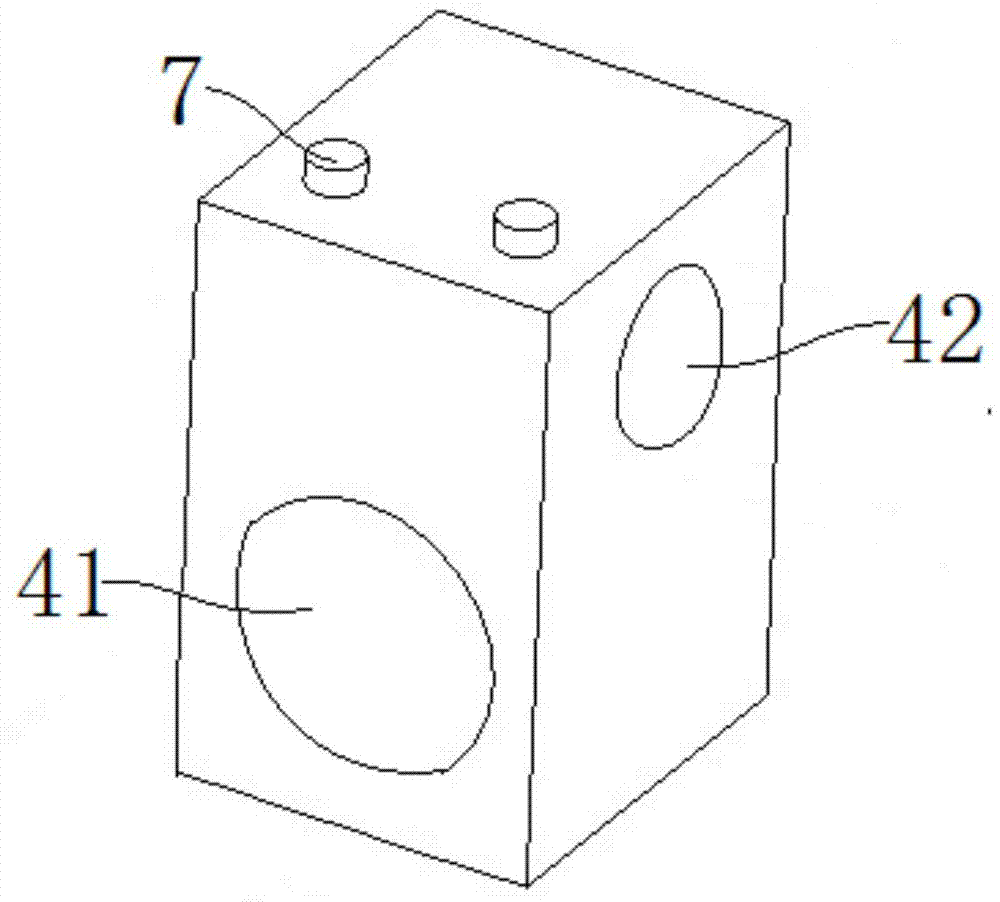

[0024] to combine figure 1 , a paper feeding mechanism of a fully automatic laminating machine adapted to conveying short-sized papers in this embodiment includes a frame 1, a fixed shaft 2, and a spacing adjustment device that is convenient for transmitting short-sized papers. The spacing adjustment device has two , and are all set on the fixed shaft 2, which can be adapted to process papers of different sizes, especially short-sized papers; the fixed shaft 2 is fixedly installed on the frame 1, and is easy to disassemble; specifically: the spacing adjustment device includes The fixed block 4, the connecting shaft 3, the connecting block 5, the adjusting bolt 7 and the locking bolt 9 are provided with a first through hole 41 and a second through hole 42 which do not interfere with each other and are perpendicular to each other, and the second through hole 42 The through hole 42 is located above the first through hole 41 (as figure 2 shown); the fixed block 4 is sleeved on t...

Embodiment 2

[0026] The basic mechanism of the paper feeding mechanism of a fully automatic laminating machine adapted to conveying short-sized paper pieces in this embodiment is the same as that in Embodiment 1, except that the included angle between the connecting block 5 and the connecting shaft 3 is 35°.

Embodiment 3

[0028] The basic mechanism of the paper feeding mechanism of a fully automatic laminating machine adapted to conveying short-sized paper pieces in this embodiment is the same as that in Embodiment 1, except that the included angle between the connecting block 5 and the connecting shaft 3 is 45°.

[0029] During use, control the adjusting bolt 7 according to the size of the paper to be conveyed, and then adjust the length of the connecting shaft 3 protruding or retracting the fixed block 4. After the adjustment, the adjusting bolt 7 is locked.

[0030] The paper feeding mechanism of the automatic laminating machine adapted to conveying short-sized paper pieces according to the present invention has ingenious structural design, convenient disassembly and operation, and can be adapted to process more paper pieces of different sizes, especially short-sized paper pieces. paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com