Feeding device

A technology of feeding device and conveyor belt, which is applied in the direction of conveyor objects, transportation and packaging, can solve the problems of hidden safety hazards and low efficiency, and achieve the effect of high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

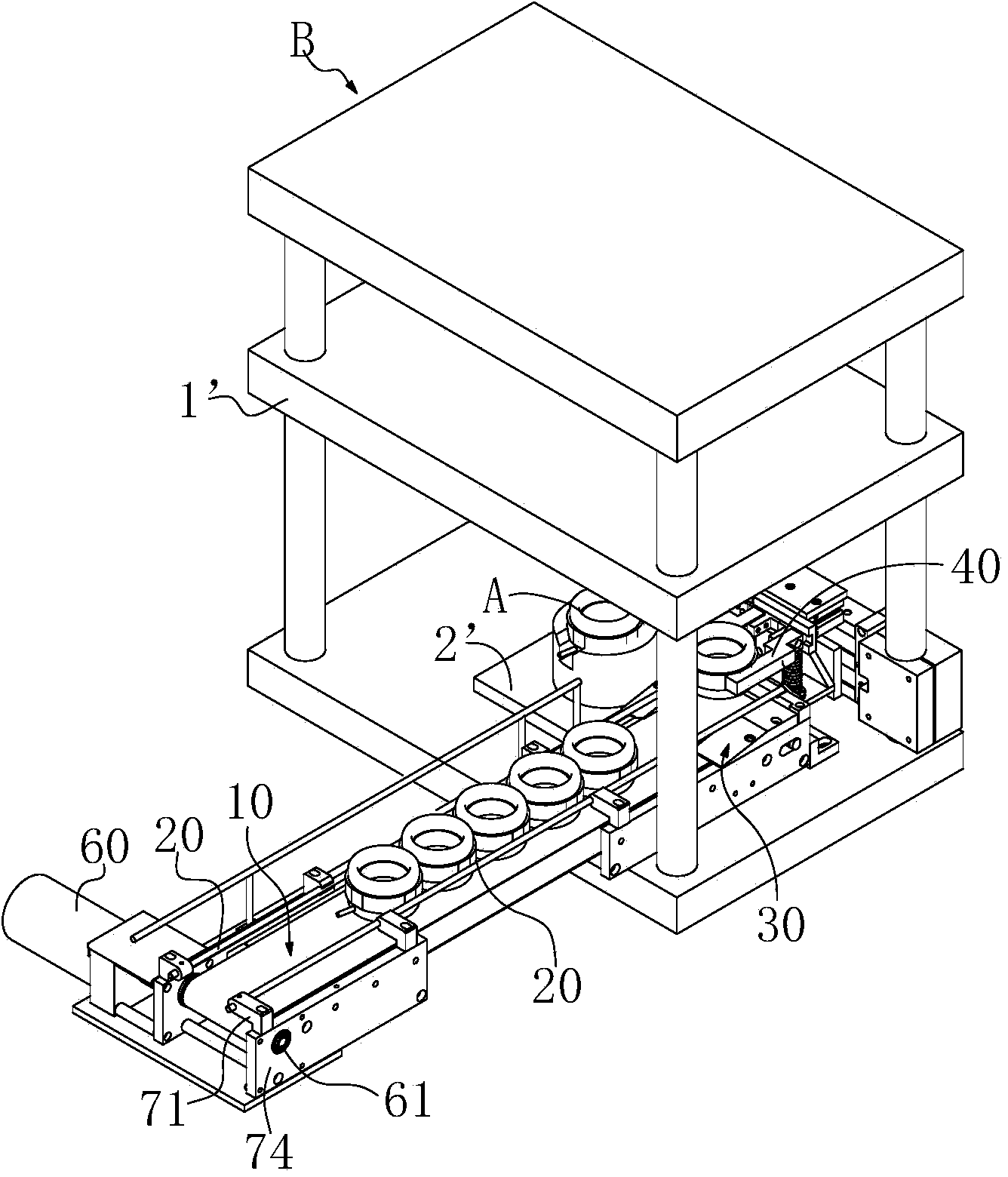

[0011] Combine below Figure 1 to Figure 4 , the present invention is further described:

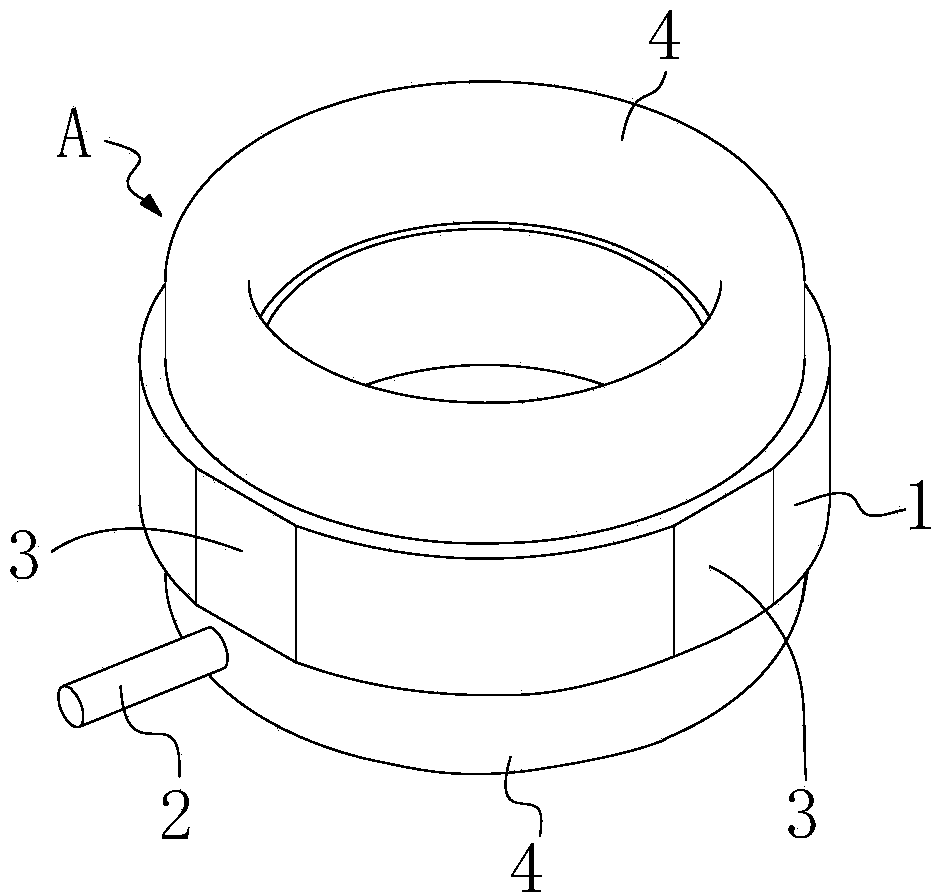

[0012] A feeding device, two limit guide rods 20 parallel to each other are arranged at the same height above the conveyor belt 10 arranged on plain cloth, the tail end of the limit guide rods 20 extends to the discharge end of the conveyor belt 10, and the end of the conveyor belt 10 The discharge end is provided with a height adjustment unit for the upper and lower relative positions between the stator primary assembly A and the limit guide rod 20. position, in other words: the distance between the lower end surface of the iron core 1 of the stator primary assembly A at the position of the adjustment unit and the limit guide rod 20 in the up and down direction is smaller than the position of the stator primary assembly A in the conveying section of the conveyor belt 10 The distance between the lower end surface of the iron core 1 at the place and the upper and lower direction of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com