High-speed stacking machine for light material boxes

A technology of stacker and material box, which is applied in the field of high-speed stacker of light material box, which can solve the problems of slow running speed, loud running noise, and inaccurate positioning, and achieve fast running speed, high positioning accuracy and complete machine compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] whole system description

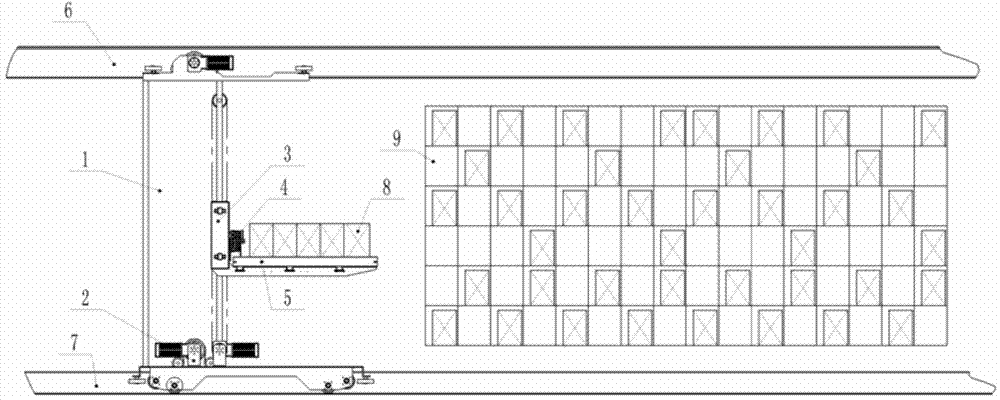

[0067] like figure 1 The schematic diagram of the whole system is shown as follows:

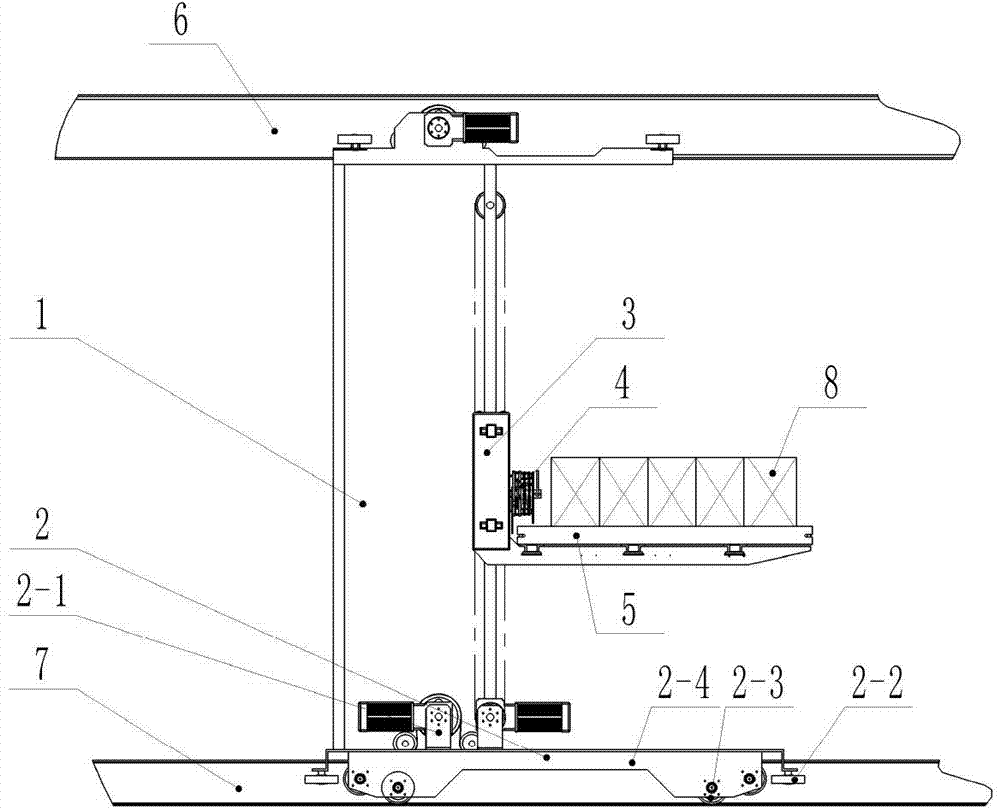

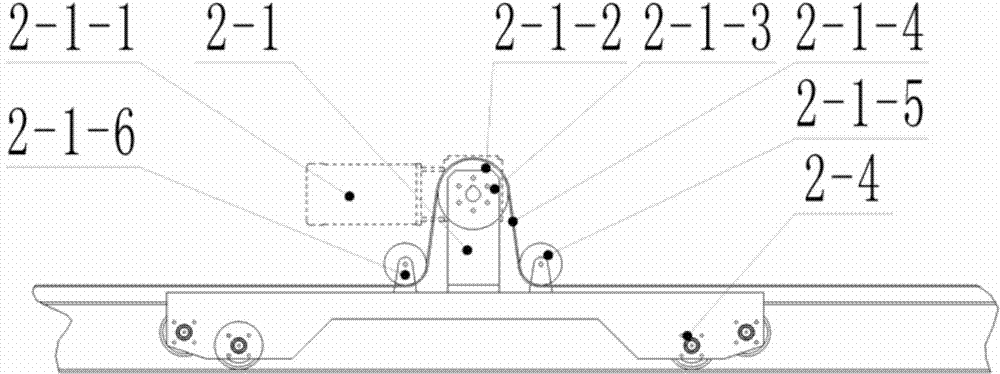

[0068] A number of material boxes 8 are neatly placed in the compartments of the shelf 9, and each compartment stores a material box 8. The light-duty material box high-speed stacker 1 travels between the sky rail 6 and the ground rail 7, and the light-duty material boxes are stacked at high speed. The machine 1 is mainly composed of a traveling device 2, a lifting mechanism 3, a telescopic fork claw mechanism 4 and a material box transfer mechanism 5. Under the action of the mechanism 3 and the traveling device 2, the claw mechanism 4 of the telescopic fork can find the position for setting the cargo grid, and pull the material box 8 into the material box transfer mechanism 5. The material box transfer mechanism 5 can carry up to 5 pieces Material box 8.

[0069] Structural description of light box high-speed stacker

[0070] The light-duty material box...

Embodiment 2

[0091]On the basis of the first embodiment, in order to eliminate the different starting and lifting resistance of the lifting motor 3-3 when the lifting platform 3-1 of the lifting mechanism 3 rises and falls, and the synchronous belt 3-6 always bears the gravity of the lifting platform, the The hoisting platform of the above-mentioned hoisting mechanism is provided with a balancing counterweight of the hoisting platform, which is formed by connecting the hoisting platform and the counterweight by a steel cable bypassing the fixed pulley on the walking frame.

[0092] This embodiment can effectively reduce the output of the hoisting motor, increase the service life, and reduce maintenance costs.

[0093]

Embodiment 3

[0095] On the basis of the second embodiment, in order to simplify the structure of the hoisting mechanism 3, it can be considered to refer to the structure of the synchronous belt drive mechanism in the traveling device: the hoisting mechanism consists of a hoisting motor, a hoisting pulley, a motor bracket, a synchronous belt, a guide wheel, and a hinge. The support is arranged on the lifting mechanism, the lifting pulley is fixed coaxially with the output shaft of the lifting motor, the two guide wheels are hinged on the hinge support, the hinge support is fixed with the lifting platform, and the synchronous belt is wound along the guide wheel in turn to lift. At both ends of the pulley, the tensioning extends to the upper and lower ends of the walking frame along the tangential direction of the guide wheel, and is fixed on the walking frame, and the synchronous belt is engaged with the lifting pulley.

[0096] In this embodiment, the length of the synchronous belt can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com