Rotary support clamping sealing tank and processing method

A processing method and a technology of supporting cards, which are applied in the directions of sealing, closing, and packaging, can solve the problems of inability to achieve the sealing effect, troublesome opening of the cover, troublesome use, etc., and achieve the effects of good sealing, convenient connection, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

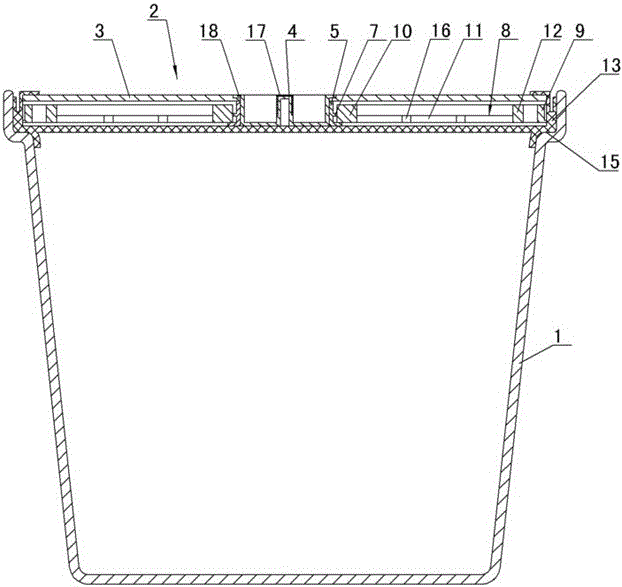

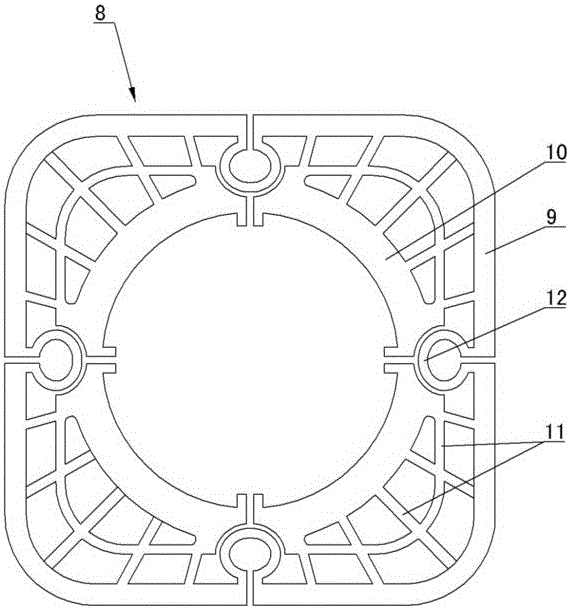

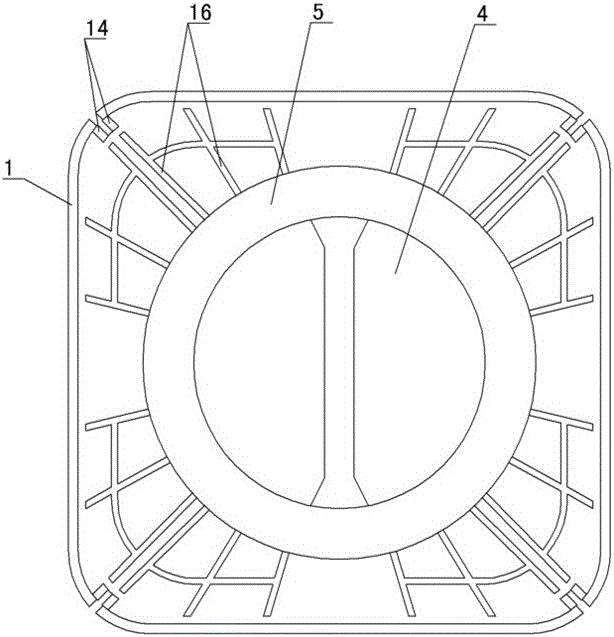

[0020] The present invention relates to a kind of rotary support clamping sealed tank, such as figure 1 — Figure 4 As shown, it includes a tank body 1 and a tank cover 2. The tank cover 2 includes a cover plate 3, a knob 4 is arranged in the cover plate 3, a knob collar 5 is installed under the knob 4, and 4 outer walls of the knob collar 5 are arranged. There is a support block 7 with a slope 6, and a support frame 8 is provided on the bottom surface of the cover plate 3. The support frame 8 includes four sides 9 corresponding to the mouth of the tank body 1 and an inner ring 10 corresponding to the knob collar 5. The inner ring 10 and four sides 9 described above are divided into four equal parts by breaking in the middle, and the inner ring 10 of each equal part is connected with the four sides 9 by a bracket 11, and the four sides 9 of each equal part are connected by an open elastic ring 12. Connected, the support block 7 with the slope 6 is in contact with the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com