Solvent-free complex method of high temperature cooking complex films and bags and complex device thereof

A technology of high-temperature cooking and composite film, applied in the field of composite film and bags, can solve the problems of large site and space, long drying section, and high design of composite equipment, so as to reduce comprehensive production costs, reduce energy consumption, and save procurement costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] For simplicity, some technical features known to those skilled in the art are omitted from the following description.

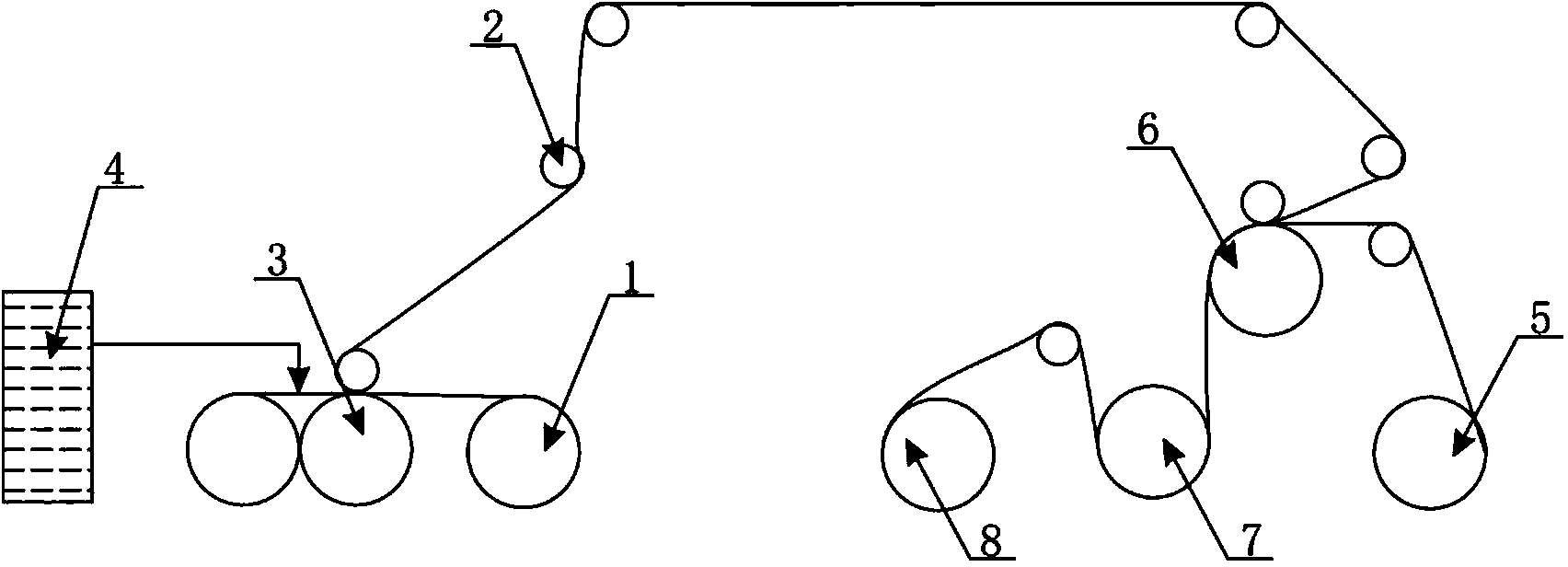

[0029] Such as figure 1 Shown in the flowchart of an embodiment of the solvent-free composite method of high-temperature cooking composite film and bag of the present invention, it includes

[0030] Put the first film in a room at 23±2°C and humidity 60±5% for 8 hours of pretreatment, and install the first film on the first unwinding device and pass it through the guide roller according to the composite direction of the film;

[0031] Put the first film into a room at 23±2°C and humidity 60±5% for 8 hours of pretreatment. The purpose is to allow the -CO-NH- on the surface of the first film to react with H20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com