Automatic warning device for numerical control cutting tool wear

An automatic alarm device and tool wear technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of surface burns, strains, scrapping and other problems of the processed materials, and achieve the effect of avoiding the reduction of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

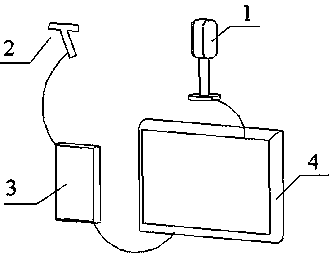

[0020] figure 1 Shown is the composition of the CNC cutting tool wear automatic alarm device of the present invention, which includes an alarm 1, a temperature sensor 2, a resistance-voltage conversion circuit 3, and an NC processor 4.

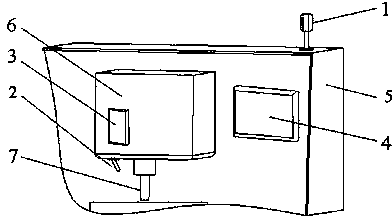

[0021] figure 2 Shown is an embodiment of the CNC cutting tool wear automatic alarm device of the present invention, wherein the temperature sensor 2 is installed on the spindle box 6 to facilitate the detection of the position of the cutting part temperature of the cutting tool 7, and the resistance-voltage conversion circuit 3 Installed inside the spindle box 6, the NC processor 4 is a part of the CNC machine tool, the alarm 1 is installed on the CNC machine bed 5, a position that is convenient for the operator to observe, and the temperature sensor 2 is processed with the NC through the resistance-voltage conversion circuit 3 The NC processor 4 is connected with the alarm 1 through a cable.

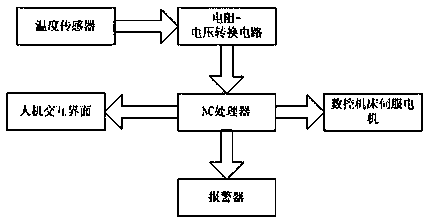

[0022] image 3 It shows the working princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com