Classification mechanism of automatic lamp inspection machine

An automatic light inspection machine and power wheel technology, applied in sorting and other directions, can solve the problems of high motor requirements, inconvenient adjustment, large space occupation, etc., and achieve the effect of low motor requirements, compact structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

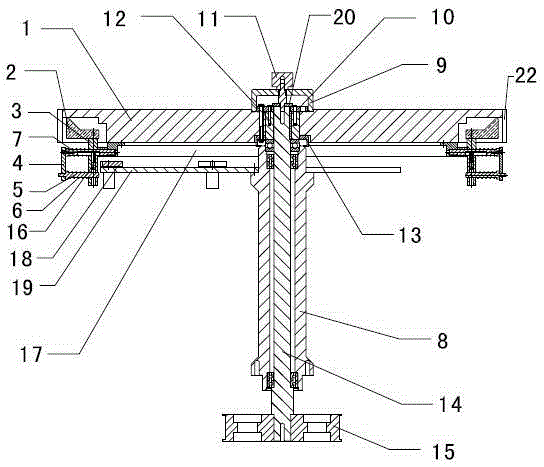

[0029] Refer to attached Figure 1~2 : the sorting mechanism of this automatic lamp inspection machine, comprises sorting dial 1, transmission device, push bottle assembly and sorting cam 18. The upper end surface of the classification dial 1 is provided with an angle adjustment disc 10, and the lower end surface of the classification dial 1 is symmetrically provided with an adjustment pressure sleeve 13 with the angle adjustment disc 10, and the bolts pass through the angle adjustment disc 10 and the classification dial 1 sequentially from top to bottom. And adjust the pressure sleeve 13 and tighten it.

[0030] The transmission device includes a fixed shaft seat 8, a mandrel 14 and a power wheel 15, the power wheel 15 is horizontally arranged at the lowermost end of the classification mechanism, the mandrel 14 is vertically fixed between the power wheel 15 and the classification dial 1, and the fixed shaft seat 8 Set on the outer side of the mandrel 14, the upper and lower ...

Embodiment 2

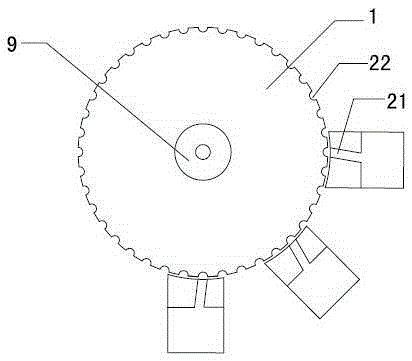

[0038] Refer to attached figure 1 And attached Figure 3-4 : the sorting mechanism of this automatic lamp inspection machine, comprises sorting dial 1, transmission device, push bottle assembly and sorting cam 18. There are three sorting cams 18, each sorting cam 18 corresponds to a sorting bottle track 21, and the other ends of the three sorting bottle tracks 21 correspond to storage areas for qualified products, unqualified products and products to be re-tested, and the rest are the same as in the embodiment 1.

Embodiment 3

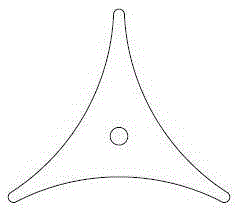

[0040] Refer to attached Figure 1~2 And attached Figure 5 : the sorting mechanism of this automatic lamp inspection machine, comprises sorting dial 1, transmission device, push bottle assembly and sorting cam 18. Classification cam 18 cross-section is quadrangular, and four sides are bent to the center, and classification cam 18 is connected with the control system of light inspection machine, rotates 90 ° at every turn, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com