Compound internal member applied to circulating fluidized bed desulfuration reactor

A technology of circulating fluidized bed and internal components, which is applied in the fields of circulating fluidized bed desulfurization reactors, internal components, and composite internal components, and can solve the problems of no significant effect of redirection, increased wear of internal components, and increased system resistance, etc. problems, to improve the effect of gas-solid mass transfer, enhance the degree of turbulence, and increase the effect of particle back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

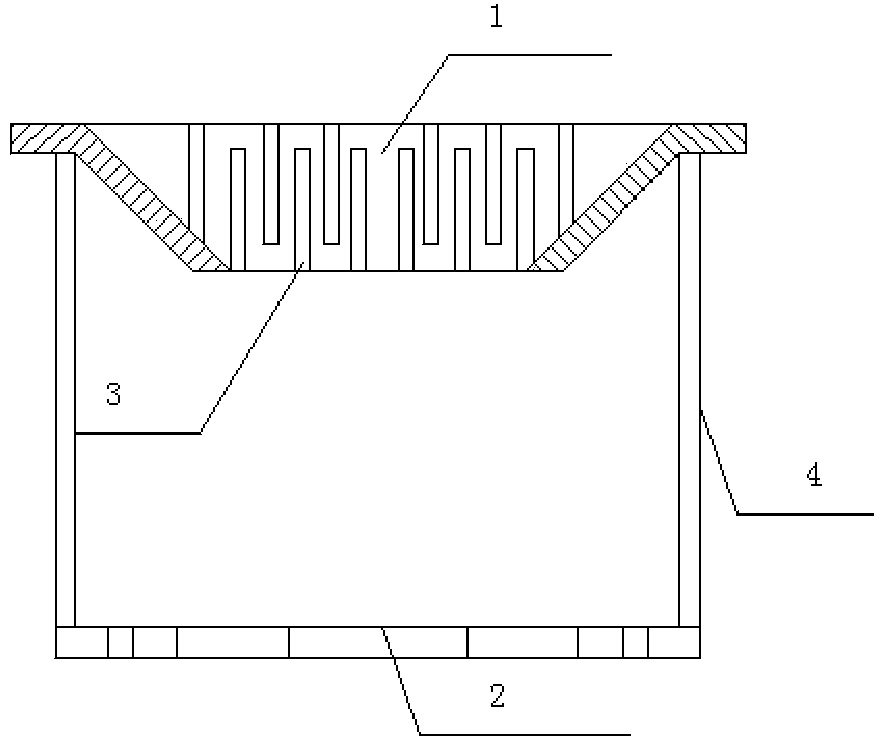

[0038] like figure 1 , figure 2 As shown, a composite internal member applied to a circulating fluidized bed desulfurization reactor, the composite internal member includes an internal member unit, the internal member is installed on the upper part of the circulating fluidized bed desulfurization reactor, and the distance from the circulation The outlet of the fluidized bed desulfurization reactor is 0.5m.

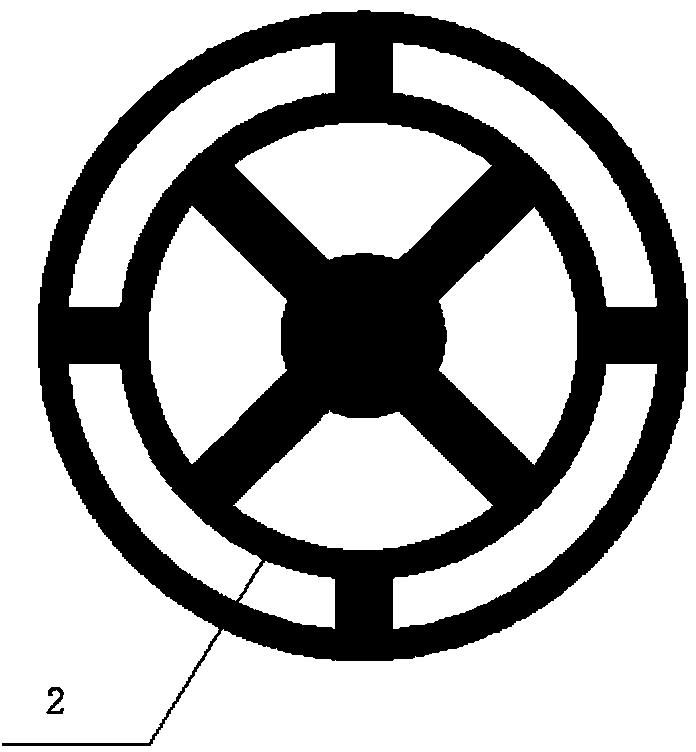

[0039] The internal component unit includes an open funnel 1 and an air distribution plate 2 . The side wall of the open-type funnel 1 is provided with a plurality of strip holes 3, which are divided into upper and lower rows and arranged alternately; the air distribution plate 2 has at least two rows of fan-shaped holes in the radial direction, and the adjacent two rows of fan-shaped holes are arranged in a staggered manner; The open funnel 1 and the air distribution plate 2 are connected by a support column 4 .

[0040] The opening ratio of the side wall of the open ...

Embodiment 2

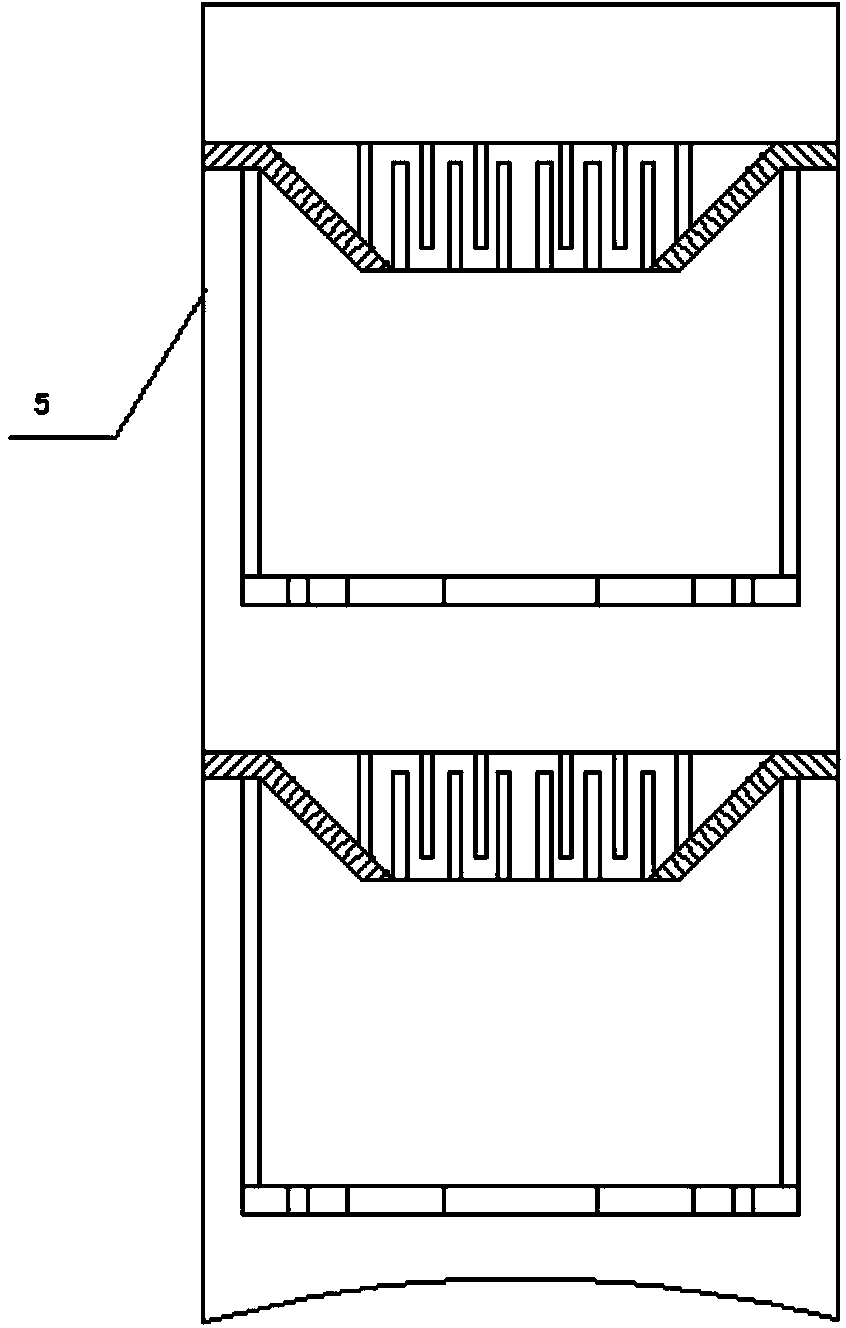

[0045] like image 3As shown, a composite internal member applied to a circulating fluidized bed desulfurization reactor, the composite internal member includes two vertically arranged internal member units, and the internal member units are installed in the circulating fluidized bed desulfurization reaction The upper part of device 5 is 1m away from the outlet of the circulating fluidized bed desulfurization reactor.

[0046] The internal component unit includes an open funnel and an air distribution plate. The side wall of the open-type funnel has a plurality of strip holes, which are divided into upper and lower rows and arranged alternately; the air distribution plate has at least two rows of fan-shaped holes in the radial direction, and two adjacent rows of fan-shaped holes are arranged in a staggered manner; the opening The type funnel and the air distribution plate are connected by a support column.

[0047] The opening ratio of the side wall of the open funnel is 70%...

Embodiment 3

[0052] A composite internal member applied to a circulating fluidized bed desulfurization reactor, the composite internal member includes three internal member units, the internal member is installed on the upper part of the circulating fluidized bed desulfurization reactor, and the distance from the circulating fluidized The outlet of the bed desulfurization reactor is 0.7m.

[0053] The internal component unit includes an open funnel and an air distribution plate. The side wall of the open-type funnel has a plurality of strip holes, which are divided into upper and lower rows and arranged alternately; the air distribution plate has at least two rows of fan-shaped holes in the radial direction, and two adjacent rows of fan-shaped holes are arranged in a staggered manner; the opening The type funnel and the air distribution plate are connected by a support column.

[0054] The opening ratio of the side wall of the open funnel is 60%. The bottom diameter of the open funnel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com