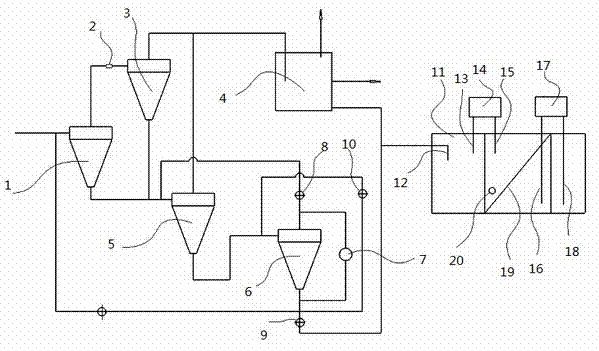

Oil-water separation system

A technology for oil-water separation and oil-water mixture, which is used in liquid separation, separation methods, and multi-stage water/sewage treatment to achieve the effects of improving sorting efficiency, simple sorting, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Do further description below in conjunction with accompanying drawing:

[0018] The oil-water separation part in this embodiment is mainly composed of the coarse separation cyclone 1 and the first to third cyclones. The coarse separation cyclone 1 roughly separates the mixed stock solution of oil and water. Since the overflow is followed by cyclone separation process, so the overflow of the coarse separation cyclone is not that the purer the oil, the better. Considering the fluidity and separability of the overflow, it is preferable that 70%-75% of the oil in the raw liquid enters the overflow item and enters the first Cyclone 3, the rest of the oil, water and most of the heavy impurities enter the underflow and lead to the second cyclone 5. If the purity of the overflow of the rough separation cyclone 1 is only pursued one-sidedly, the oil cannot be swirled because it is too thick. flow separation, and the selected amount of the entire separation system is greatly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com